A Highlight of Aluminum Flashing Roll

The aluminum flashing roll a versatile product used in roofing areas. The two common specifications are 24inch and 48 inch aluminum flashing roll. How to control its quality? Learn more.

The aluminum flashing roll a versatile product used in roofing areas like fascia covers, siding, gutters, chimney flashing,etc. It is a necessary element for most dwellers to weatherproof their homes. The two common specifications are 24inch and 48 inch aluminum flashing roll.

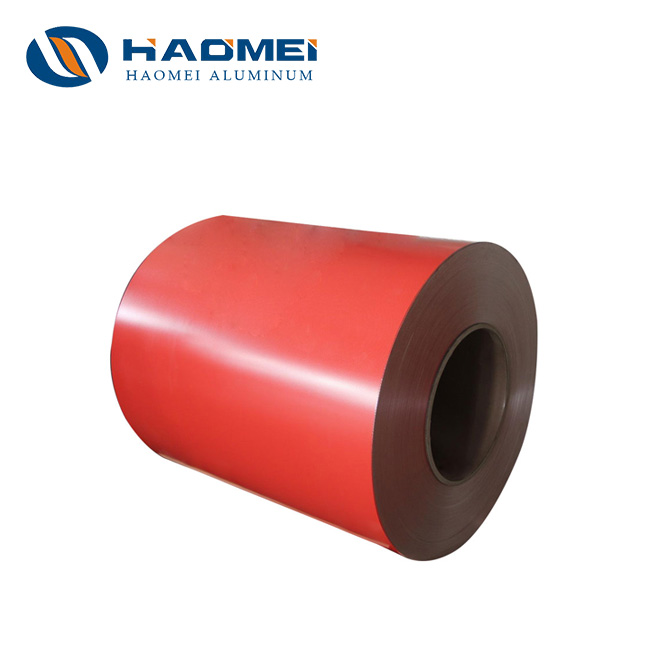

The paint thickness of color coated aluminum coil is one of the important factors affecting its performance and quality. Too much or too little paint thickness will lead to defects and problems of color-coated aluminum coils. Excessive paint thickness will increase the cost, reduce the hardness and flexibility of the coating, affect the adhesion and corrosion resistance of the coating, and easily cause defects such as sagging, wrinkles, and air bubbles.

If the paint thickness is too small, the coverage and hiding power of the coating will be reduced, the color and luster of the coating will be affected, and defects such as scratches, wear, and peeling will easily occur.

Therefore, controlling the paint thickness of aluminum flashing roll s a key link to ensure its quality and performance. The paint thickness of color-coated aluminum coils is affected by many factors, mainly in the following aspects:

The choice of plain aluminum coil

The quality and surface treatment of raw materials directly affect the bonding force and flatness between the coating and the substrate. Raw materials should select appropriate alloy series, hardness, thickness and other parameters, and carry out cleaning, pretreatment, primary (finish) coating and other processes to improve its corrosion resistance and adhesion to the upper paint film.

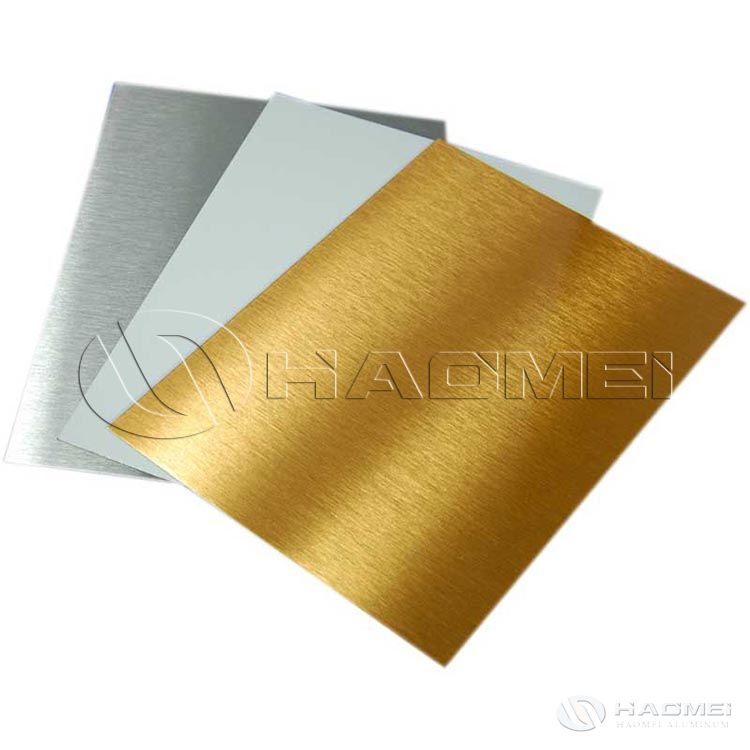

Types and properties of coatings

Different types and properties of coatings have different requirements for coating thickness. According to the paint, there are PVC coated aluminum coils, polyester coated aluminum coils, acrylic coated aluminum coils, fluorocarbon coated aluminum coils, silicon polyester coated aluminum coils, etc. Among them, PVDF aluminum coil is the highest-grade product, which has the most excellent weather resistance and anti-ultraviolet performance, but also requires a higher paint thickness, generally more than 25 microns.

Coating process and equipment

Different coating processes and equipment have different control precisions for paint thickness. According to different coating methods, there are organically coated aluminum coils produced by roll coating, spray coating, powder coating, laminating, printing, etc. Among them, the roller coating method is the most commonly used method, which evenly distributes the pre-adjusted paint on the substrate through the roller, and forms a continuous and uniform paint film by baking and curing.

Parameters such as the shape, size, speed, and gap of the roller will affect the quantity and distribution of the roller coating, thereby affecting the coating thickness of the final product.

To sum up, the paint thickness of the 24 inch aluminum flashing roll is a complex and important issue, which needs to be considered comprehensively according to the product's use, performance requirements, cost control and other factors, and corresponding measures should be taken for monitoring and adjustment. Generally speaking, the standard paint thickness range for color-coated aluminum coils is 15-25 microns.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China