Gutter Coil

Gutter coil guide for bulk buyers: aluminum coil stock specs, alloys, coatings, sizing, and QC tips for durable gutters and fascia trim.

What is gutter coil?

Gutter coil (also called aluminum gutter coil or gutter coil stock) is a continuous roll of thin aluminum sheet used to fabricate gutters, fascia wraps, drip edge, and other exterior trim parts. Its designed to be run through a gutter machine or brake-formed on site, giving contractors and fabricators a fast way to produce consistent profiles in the exact lengths needed.

For bulk buyers of aluminum sheet, coil, strip, and foil, the confusion usually comes from mixing up (1) coil width vs. finished gutter size, (2) gauge/thickness vs. weight, and (3) paint system vs. the visual color alone. The sections below clarify the essentials so you can specify the right gutter coil for your production and jobsite conditions.

Common applications and why coil format matters

Gutter systems demand long, straight, blemish-free runs. Coil form delivers that efficiency:

Seamless gutters: Coil feeds directly into forming machines, minimizing joints and leak points.

Fascia and trim wrapping: Coil is brake-formed for clean edges and consistent bend radii.

Drip edge and flashing: Coil can be slit and formed into protective transition pieces.

From an operations perspective, coil reduces scrap vs. cutting sheets, speeds line changeover, and improves inventory density (more square meters per pallet position).

Key specs to choose (alloy, thickness, width, coating)

The right gutter coil is a balance of formability, dent resistance, corrosion performance, and appearance.

Alloy and temper

Most gutter coil is produced in formable aluminum alloys suitable for bending and roll-forming. When quoting, confirm:

Alloy: common exterior building alloys are chosen for corrosion resistance and workability.

Temper: softer tempers form easier but can dent more easily; harder tempers resist dents but may crack on tight bends.

Thickness (gauge)

Thickness drives stiffness, dent resistance, and how the coil behaves in forming.

| Spec factor | What it affects | Practical note for bulk orders |

|---|---|---|

| Thickness (mm or gauge) | Dent resistance, rigidity | Thicker isnt always better if your forming equipment is tuned for a specific range |

| Width (in/mm) | Which gutter/trim profiles you can form | Width must match the machine/forming design, not the final visible face |

| Inside diameter (ID) | Uncoiler compatibility | Confirm ID to prevent production downtime |

| Coil weight | Handling and freight | Align with your warehouse lifting capacity and racking limits |

Width selection

Widths are typically chosen based on the gutter profile (e.g., K-style, half-round) and the trim/flashing design. For jobsite flexibility, some buyers standardize a few widths to simplify SKU management.

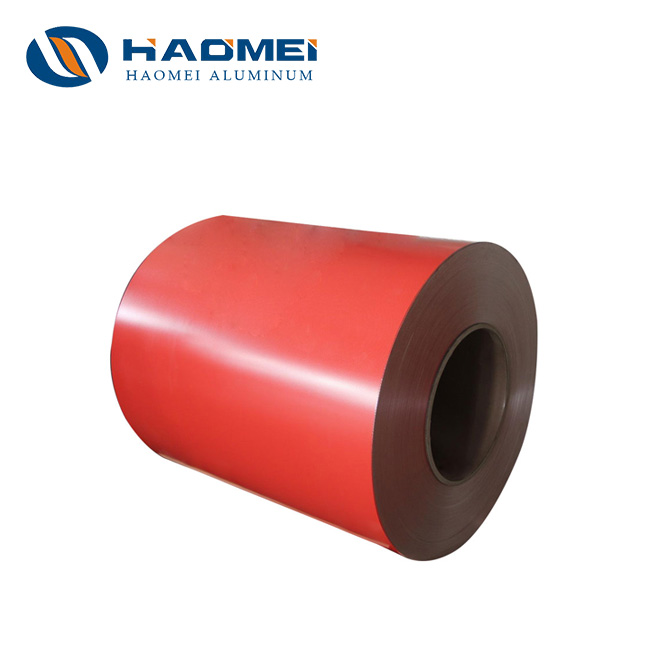

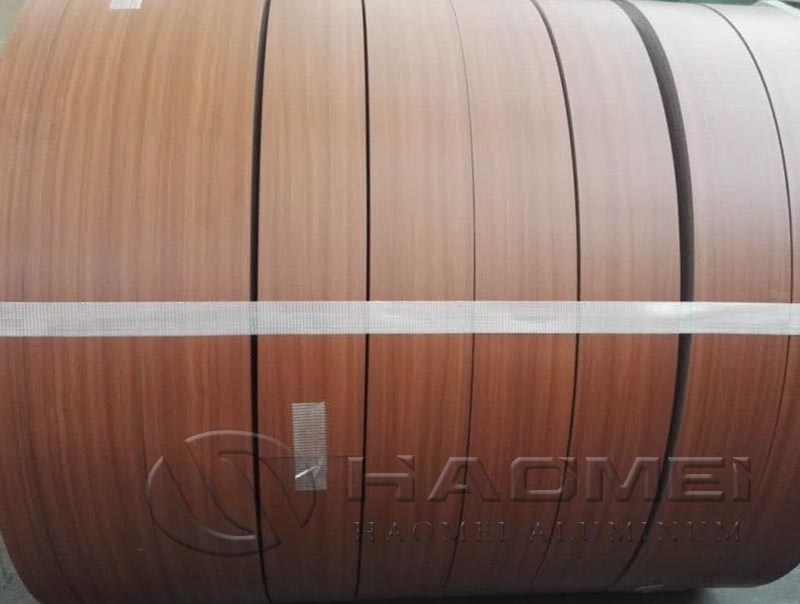

Coating system and finish

Exterior gutter coil is often prefinished for UV stability and color consistency. Paint type, primer, and topcoat thickness matter as much as the color chip.

If your customers require specific aesthetics (matte, gloss, textured, wood grain), consider specifying prefinished options so the alumium gutter coil arrives ready for forming with consistent appearance across batches.

How to buy gutter coil in bulk: a practical checklist

Bulk purchasing is less about finding a roll and more about controlling variation across runs.

Define the end use: seamless gutters vs. fascia wrap vs. flashing. Each has different bend requirements and exposure.

Lock the critical dimensions: thickness tolerance and width tolerance should be clearly stated in the PO.

Confirm coating performance: request coating specs suitable for outdoor UV and moisture exposure, especially in coastal or industrial areas.

Specify surface protection: ask for interleaving or protective film when cosmetic appearance is critical (e.g., darker colors show scuffs more easily).

Packaging and handling: clarify pallet type, edge protection, wrap, and labeling (heat number, coil number, net/gross weight).

Quality checks to reduce claims

For incoming inspection, focus on measurable items:

| Inspection item | What to look for | Why it matters |

|---|---|---|

| Thickness across the coil | Consistency edge-to-center | Prevents forming issues and uneven profiles |

| Coating appearance | Color consistency, pinholes, scratches | Reduces jobsite rejections and callbacks |

| Edge condition | Burrs, wave, camber | Impacts slitting, feeding, and safe handling |

| Coil set / flatness | Excess memory, waviness | Affects brake forming and finished visual lines |

If you distribute to multiple crews or regions, consider keeping a retained sample and recording coil IDs by job. This improves traceability if a color or gloss complaint arises months later.

FAQs about gutter coil

Is gutter coil different from regular aluminum coil?Functionally its aluminum coil optimized and commonly stocked for gutter/trim fabricationoften prefinished, with widths and tempers aligned to forming practices.

What causes cracking at bends?Usually an alloy/temper mismatch, too-tight bend radius, or low-temperature forming. Confirm temper, adjust tooling, and ensure the coating system supports forming without micro-cracking.

How do I prevent color mismatch across projects?Standardize paint system and supplier, specify color tolerance, and buy enough for a project batch when possible. Prefinished options like PE coated aluminum coil help maintain consistency when ordered to a defined spec.

Whats the biggest spec mistake in POs?Ordering by gauge name without stating actual thickness and tolerance. Always include mm (or inch) thickness plus allowable deviation.

Bottom line

Gutter coil is a production-focused aluminum coil stock used to form gutters and exterior trim efficiently. For bulk buyers, the best outcomes come from specifying thickness/width clearly, matching alloy and temper to your forming method, and treating coating performance as a functional requirementnot just a color choice. With consistent specs, packaging, and incoming QC, you can reduce scrap, avoid jobsite rejections, and keep high-volume fulfillment predictable.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China