How to Choose Different Types of Coated Aluminum Coils

There are two types of coated aluminum coils: PVDF coated aluminum coil and PE coated aluminum coil. What are its manufacturing process and how to choose proper ones? Learn more.

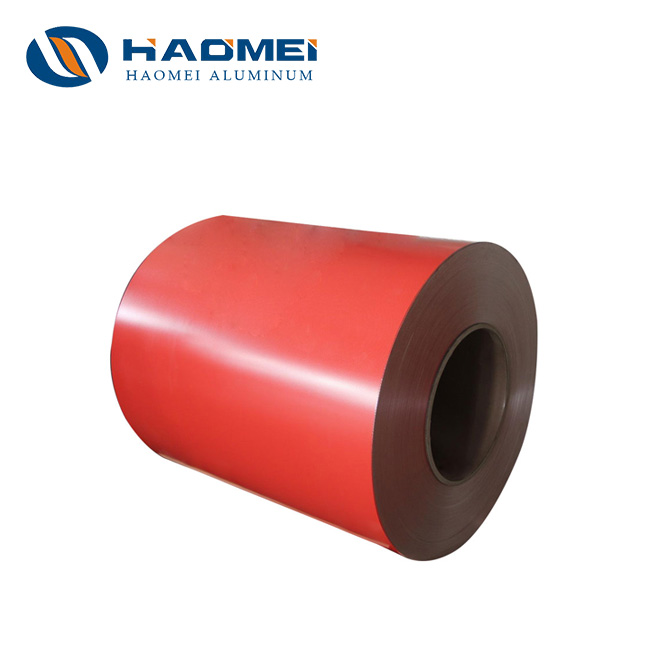

The coated aluminum coil refers to the aluminum coil that are coated with one or more layers of organic coatings. It has the advantages of being lightweight, corrosion-resistant, easy to process, and environmentally friendly, and is widely used in construction, home appliances, transportation, decoration and other fields. The production process of colored aluminum mainly relies on roller coating.

Types

According to the type of coating, color coated aluminum coils can be divided into two categories: PVDF coated aluminum coil and PE coated aluminum coil.

PVDF coated aluminum coil

It refers to coating the surface of the aluminum coil with a coating containing fluorocarbon resin to form an aluminum product with excellent weather resistance, UV resistance, chemical corrosion resistance and self-cleaning properties. Fluorocarbon pre-coated aluminum coils are suitable for high-end building curtain walls, roofs, ceilings and other occasions, and their service life can reach more than 20 years.

PE coated aluminum coil

It refers to coating the surface of the aluminum coil with coating containing polyester resin to form an aluminum product with good adhesion, rich colors and environmental protection performance. This precoated aluminum coil is suitable for indoor and outdoor decoration, doors, windows, home appliances and other occasions, and their service life can reach about 10 years.

Manufacturing process

Uncoiling

Put the aluminum coil into the uncoiler and unroll it into a flat strip.

Cleaning

The uncoiled aluminum strip is fed into a cleaning machine, and acid and alkali solutions are used to remove oil and rust to make the surface clean and smooth.

Preprocessing

The cleaned aluminum coil is fed into the pre-treatment machine, and a conversion agent is used to chemically convert it to form a dense and uniform conversion film to enhance its adhesion to the paint.

Painting

The pretreated aluminum coil is fed into the coating machine and sprayed with primer and topcoat one or more times with a roller or spray gun to form a coating with the desired color and effect.

Solidifying

The coated aluminum coil is is sent into a curing oven and dried and cured at high temperature to achieve the required hardness and gloss.

Cutting

The cured aluminum coil is fed into the cutting machine and cut longitudinally and transversely according to the customer's requirements to obtain pre-coated aluminum coils of the required specifications and sizes.

Inspection

During the production and manufacturing process, the quality of color aluminum coils needs to be tested, including surface quality, flatness, thickness, etc.

Package

The processed color aluminum coils are packaged and appropriate protective measures are taken to ensure that they will not be damaged during transportation.

How to purchase color aluminum coils

When purchasing color aluminum coils, you should choose a reputable aluminum coil manufacturer. You should consider it from the following aspects:

Processing performance

Since color aluminum coils require stamping, cutting, bending and other processing operations, their processing performance should be fully considered when purchasing. Choosing color aluminum coils with good processing properties can reduce processing difficulty and improve production efficiency.

Specifications

According to the needs of the actual application scenario, select the color aluminum coil with appropriate thickness, width and length to ensure that it meets the usage requirements. At the same time, it should be noted that color aluminum coils of different specifications may differ in price and quality, so a reasonable selection needs to be made based on budget and actual needs.

Surface treatment quality

The surface treatment quality of color aluminum coils has an important impact on its aesthetics and durability. When purchasing, you should pay attention to the adhesion and wear resistance of the surface coating to ensure it has a long service life and good decorative effect.

Relevant standards and regulations

Colored aluminum coils for different uses may be subject to different standards and regulations, such as safety performance requirements and environmental protection requirements for building exterior wall decoration materials.

Haomei Aluminum is one of the reputable aluminum gutter coil suppliers in China. Welcome to leave message below to tell us what you need.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China