Aluminum Trim Coil for 6 Inch Gutter

6 inch gutter coil usually has two specifications: 0.032" x 15" and 0.027" x 15". Aluminum trim coil for gutter usually chooses 1xxx pure aluminum, 3xxx Al-Mn alloy, 5xxx Al-Mg alloy and 6xxx Al-Mg-Si. Learn more.

The color coated aluminum coil for making gutter usually chooses 1xxx pure aluminum, 3xxx aluminum-manganese alloy, 5xxx aluminum-magnesium alloy and 6xxx aluminum-magnesium-silicon alloy. The thickness of the aluminum coil is divided into 0.6, 0.7, 0.8, 0.9, 1.0, 1.1, 1.2, 1.5, etc. 6 inch gutter coil usually has two specifications: 0.032" x 15" and 0.027" x 15".

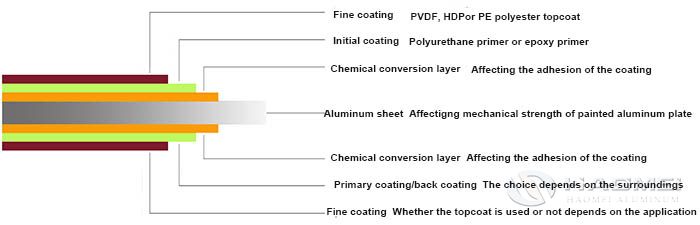

The surface of the aluminum coil has been specially cleaned, and then electrostatically sprayed with a colored outdoor polyester coating. The thickness of the coating is not less than 20umd. The weather resistance of the coating is not less than 7 years, and the high weather resistance, high hardness, wear resistance and impact resistance meet the export environmental protection requirements.

AA3004 aluminum-magnesium-manganese alloy is generally recognized as a roofing and exterior wall material with a service life of more than 50 years in architectural design due to its moderate structural strength, weather resistance, stain resistance, and easy bending and welding processing. In response to architectural design in marine climates, 5052 marine-grade aluminum alloy materials with stronger corrosion resistance can be used.

Roller coating is an important process in the pre painted aluminum coil production line. The quality of sprayed products, especially the appearance quality, will directly affect the decoration effect. But even if you pay attention to the processing, there will always be quality defects. There are several factors leading to the defects of aluminum trim coil.

1. Defects in processing technology

The spraying process is closely related to the spraying quality, and the relative linear speed of the spraying roller, coating roller, measuring roller and plate is controlled within a certain range. The coating should set a certain viscosity range according to different systems and the film thickness of the coated aluminum coil, so as to ensure the smooth progress of the coating and promote the improvement of product quality. Coating drying and curing process, and the operation of the drying oven must be carried out according to the requirements, and cannot be changed at will, otherwise the coating effect will be seriously affected.

2. Raw material defects

Coatings and aluminum coils are important factors affecting the quality of coatings. Because the color difference of different batches, nsufficient coating particle size, low coating rate, poor coordination between the coating and organic solvents, etc. will directly affect the actual effect of the coating, resulting in uneven aluminum coils, uneven film thickness, and poor edge deflection values.

3. Defects of human factors

The proficiency and operating specifications of the operators of aluminum trim coil manufacturers are the basis for high-quality spraying. Therefore, it is necessary to strengthen the training of actual operating staff to ensure the spraying quality of the product.

4. Defects in machinery and equipment

The spraying equipment should be intact, stable in operation, without horizontal or vertical vibration, and the spraying roller should be finely ground. The horizontal vibration of all the rollers of the coating machine should be controlled within the allowable range, otherwise it will seriously affect the quality of the coating surface.

5. Natural environment defect

The internal structure of the spraying room should be kept clean, anti-fouling, anti-moth, and naturally ventilated to ensure that the quality of the sprayed surface will not be polluted by the environment. As the temperature changes, the processing technology standards should also be adjusted accordingly.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China