Different Forms of 1050 Aluminum

Among aluminum alloys, 1050 aluminum alloy has become an indispensable material in industrial production and daily life due to its high purity (aluminum content ≥99.5%), excellent thermal conductivity, good plasticity, and corrosion resistance.1050 a

Among aluminum alloys, 1050 aluminum alloy has become an indispensable material in industrial production and daily life due to its high purity (aluminum content ≥99.5%), excellent thermal conductivity, good plasticity, and corrosion resistance.

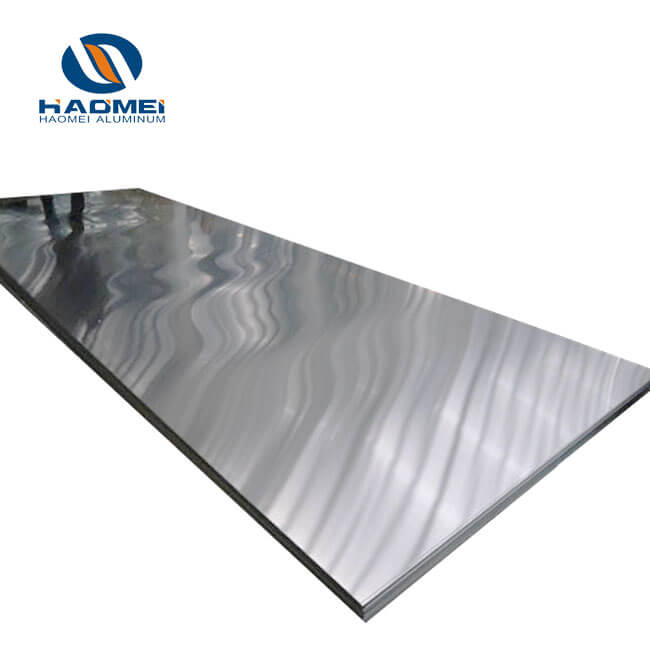

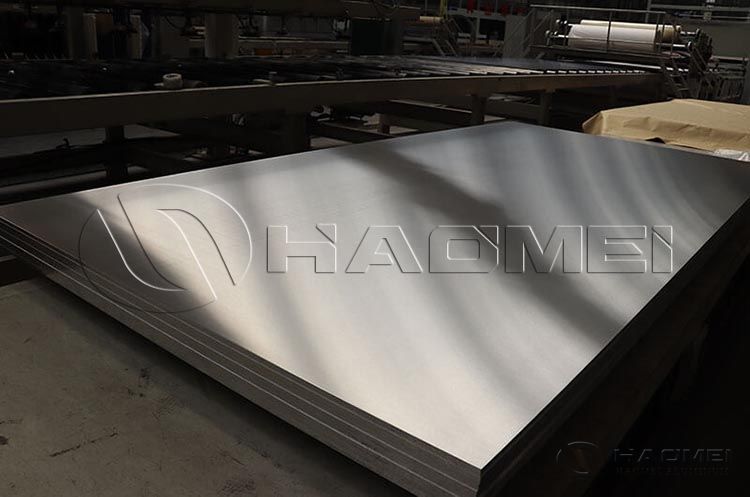

1050 aluminum sheet

1050 aluminum sheet typically comes in flat sheet form with a wide range of thicknesses (generally ranging from 0.2mm to 50mm). Its core advantages lie in its ease of processing and strong stability. Its common tempers are 1050-O, 1050 h18 and 1050 h14 aluminium.

1050-O aluminum: After full annealing, the O-state achieves optimal plasticity, enabling it to meet nearly any complex stamping and bending requirements. Its surface is also smooth and flat, making it suitable for subsequent surface treatments such as painting and printing.

This aluminum sheet is often used in decorative applications, such as interior wall panels and advertising signboards. It is also widely used in home appliance manufacturing, with applications such as refrigerator side panels and washing machine housings relying on the formability and excellent surface quality of O-state aluminum sheet.

1050h14/h18 aluminum sheet: After partial or full cold rolling, the sheet's strength is significantly increased. While its plasticity decreases slightly, it can withstand certain external impacts. H14 aluminum sheet, due to its moderate strength, is often used in kitchenware manufacturing, such as frying pan bodies and baking tray bases. It ensures stability during use and is easy to process into various shapes.

The stronger H18 aluminum sheet is more commonly used in structural support applications, such as frames for small devices and furniture connectors, where its higher hardness reduces the risk of deformation.

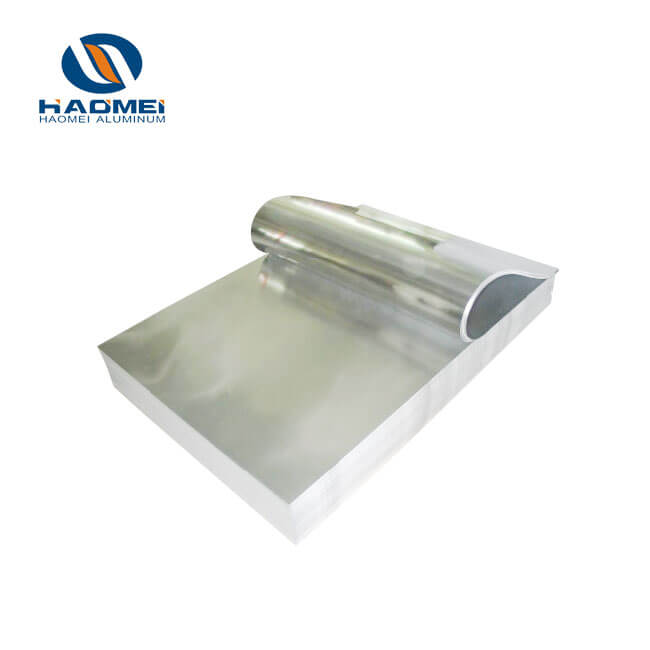

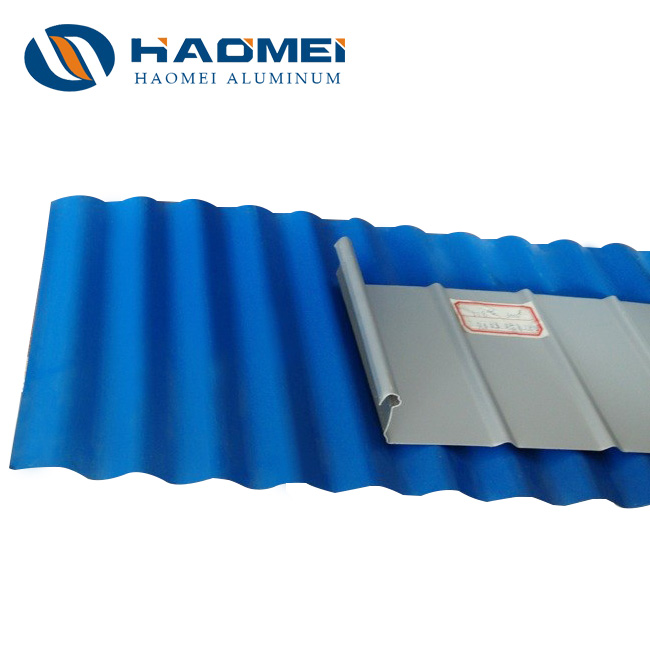

1050 aluminum coil

1050 aluminum coil is supplied in coils, reaching lengths of tens or even hundreds of meters, with thicknesses typically ranging from 0.1mm to 3mm. Its core characteristic is its strong continuous processability, so it prefers a state that maintains good ductility and a smooth surface. 1050-O and 1050 h12 aluminum coils are more common.

1050-O aluminum coil: Due to its excellent plasticity, O-state aluminum coil is ideal for continuous stamping and shearing processes, such as the mass production of small aluminum parts (such as gaskets and connectors in electrical appliances). Its rolled form reduces the complexity of sheet splicing, significantly improving production efficiency.

1050-O-state aluminum coil also has a smooth surface and is often used as a substrate in packaging, such as the inner layer of aluminum-plastic composite film, where subsequent lamination enhances barrier properties. Furthermore, in architectural decoration, O temper aluminum coil can be roll-formed into corrugated or embossed sheeting for wall or roof decoration. The continuous coil material is suitable for large-scale construction.

1050-H12 aluminum coil: After a light cold rolling process, H12 aluminum coil maintains a certain degree of ductility while boasting slightly higher strength than O-grade aluminum, making it ideal for applications requiring light forming. For example, in the automotive industry, it's used to create decorative strips for vehicle interiors.

Aluminum coil can be bent and cut into decorative pieces of varying lengths, ensuring styling flexibility while withstanding the slight friction of daily use. In home appliance parts, H12 aluminum coil can also be used to create air conditioner vent frames and microwave oven housings, balancing ease of processing with stability.

1050 aluminum foil

1050 aluminum foil is the lightest and thinnest of the three types, typically ranging in thickness from 0.006mm to 0.2mm, and can even reach the micron level. Its core advantages are ultra-thinness, easy lamination, and strong barrier properties. Therefore, it has more stringent requirements for its condition, and is almost exclusively used in O temper.

Food packaging: 1050 aluminum effectively blocks oxygen, moisture, and light, extending the shelf life of food. It is non-toxic and harmless, meeting food-grade safety standards. Furthermore, 1050 aluminum foil is commonly used in household applications. Its high thermal conductivity ensures even heat transfer during grilling and baking, preventing food from burning.

Electronics and electrical sector: Ultra-thin 1050 aluminum foil can be used for electromagnetic shielding, such as wrapping around wires and cables to reduce electromagnetic interference. In lithium battery manufacturing, 1050 aluminum foil can also be used as the positive electrode current collector.

Pharmaceutical packaging: 1050 aluminum foil is often used in "aluminum-plastic blister packaging" (such as for capsules and tablets). This provides a barrier against moisture and microorganisms while also making it easy for consumers to access the contents. Furthermore, the foil's chemical stability is strong, preventing it from reacting with pharmaceuticals, ensuring safe use.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China