7075 2024 Aluminum Sheet Plate

The most widely used aircraft sheets are 2000 and 7000 series aluminum alloys like 7075 and 2024 aluminum sheet. What are their main elements and properties? They features high strength. Learn more.

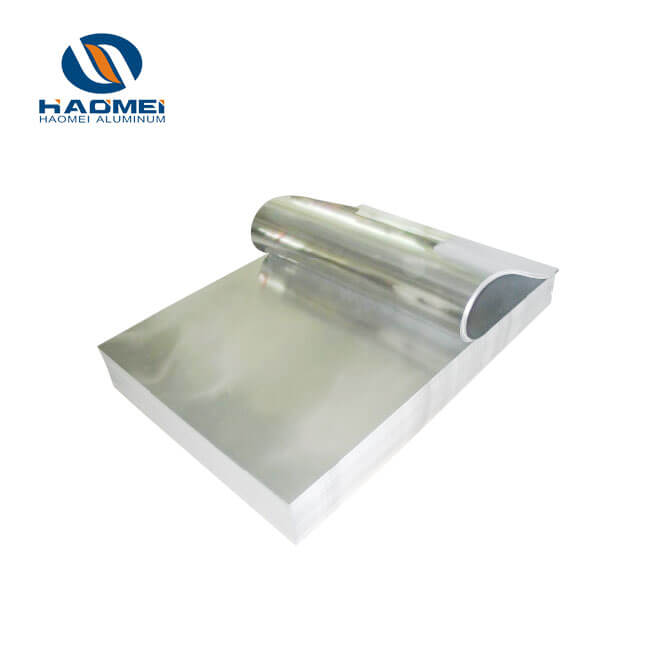

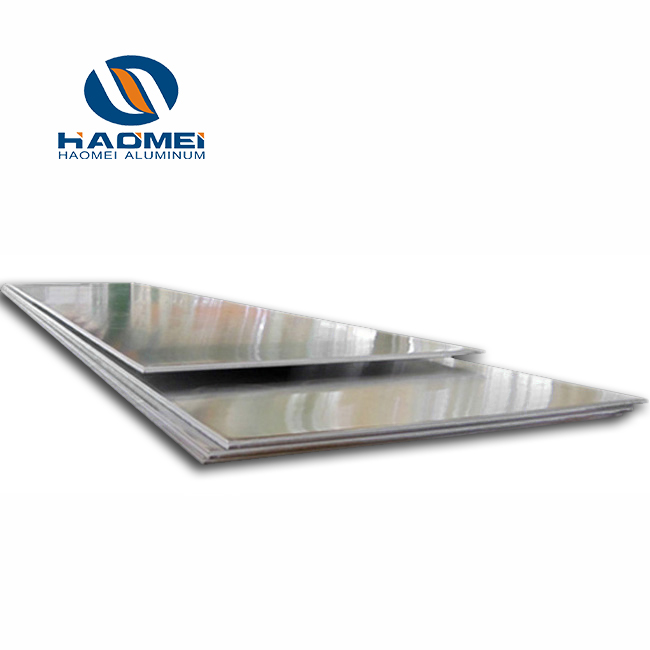

Ultra-high-strength aircraft aluminum sheet generally refers to aluminum alloys with a a yield strength of more than 500MPa, and the most common ones are ultra-duraluminum 7000 series. This series of aluminum alloys was originally developed under the background of aerospace applications, and has now developed into the main structural materials of military and civil aircraft in the world, accounting for 70-80% of aircraft structural parts.

As a relatively mature lightweight high-strength alloy material, aluminum alloy is widely used in aerospace. Aluminum alloy materials like 7075 aluminum plate are generally used as structural materials, which have higher specific strength and better processing performance than steel.

The aerospace field mainly develops high-strength, high-toughness and strong corrosion-resistant aluminum alloy materials to meet the harsh conditions of use in aerospace. The most widely used are 2000 series and 7000 series. The main components of 2000 series aluminum alloys are mainly aluminum (Al), copper (Cu), and magnesium (Mg). The main components of 7000-series aluminum alloys are Al, zinc (Zn), Mg, and Cu elements.

The 2000 series aluminum alloy mainly uses Cu as the main alloying element. The alloy prepared by adding an appropriate amount of Cu element to the aluminum alloy material will have a better improvement in strength, heat resistance, and processing performance, but the corrosion resistance will decrease.

Therefore, for 2000 series aluminum alloys like 2024 aluminum sheet, pure aluminum or 6000 series aluminum alloys are generally coated on their surface as an electrochemical protective film to improve their corrosion resistance.

Generally speaking, the development direction of aluminum alloy is from high strength, low toughness to high strength, high toughness, and then to high strength, high toughness, and corrosion resistance. The development of heat treatment state develops from T6 to T73 to T76 to T736 to T77.

The degree of alloying is getting higher and higher, the content of impurities such as Fe and Si is getting lower and lower, and the addition of trace transition elements is becoming more and more reasonable, and finally the overall performance of the alloy is comprehensively improved.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China