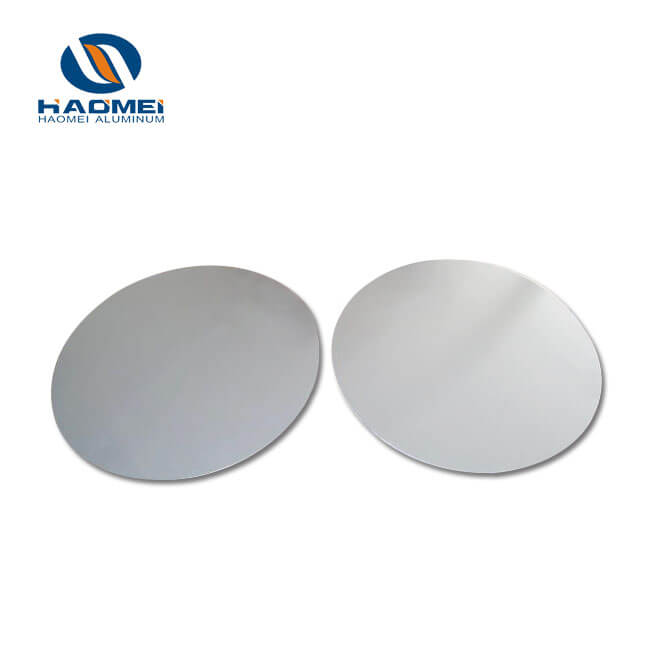

Aluminium Circle 1060 for Spinning

Aluminium circle 1060 belongs to the pure aluminum and has good ductility. It is especially suitable for deep stamping, spinning,drawing,etc. Its common tempers are H14/H24, H18, H0,etc.

Aluminum discs are mainly targeted at customers with deep stamping, spinning,drawing and other processing techniques and are suitable for kitchenware, lighting, and tanks. Aluminum discs are generally made of 1060-0 or 1060 semi-hard. In this state, they will not crack during stamping, spinning, etc. during the later production process.

Aluminium circle 1060 belongs to the pure aluminum and has good ductility. 1060 aluminum circle has good bending ability and deep drawing performance. Compared with other aluminum alloys, 1060 aluminum has higher electrical conductivity and thermal conductivity, and is suitable for manufacturing electrical components, radiators and other products. In addition, 1060 aluminum discs have excellent corrosion resistance and can remain stable in humid environments.

1060 aluminum disc circle can be roughly divided into H14/H24, H18, H0 and other tempers according to different annealing treatment times. The hardness and elongation of different states are different, and the performance is also different.

1060-H14/H24 aluminum is a semi-hard aluminum with a tensile strength of around 120 MPa and an elongation of around 10%. This aluminum plate is the most commonly used product in bending processing. It has high strength and good bending performance without cracking.

1060-H18 aluminum circle is a product with the highest hardness and strength among 1060 aluminum plates. The tensile strength is around 150MPa and the elongation is within 3%. It is not suitable for bending but is suitable for punching products. Due to the high hardness, no burrs will be left after punching.

1060-H0 aluminum plate is an aluminum plate with low hardness, also known as ultra-soft aluminum plate. It has basically no strength and is suitable for products that require deep stamping and stretching, such as lampshades, tanks, and utensils.

The production process of 1060 aluminum round plate can be divided into two types: casting and hot rolling. The 1060 aluminum plate produced by casting and rolling is cheaper, the grain size is not as uniform as hot rolling. In large-scale deep stamping process, cast-rolled aluminum discs do not have as high an elongation as hot-rolled. At the same time, hot-rolled aluminum circle like 12 aluminum disc can be anodized, but since the price of the hot-rolled 1060 aluminum circle is much higher than that of the cold-rolled series, the market demand of the hot rolled aluminum circle is not too big.

As one of the big aluminum discs suppliers in China, Haomei Aluminum has rich alloys of aluminum circles with complete specification. Welcome to leave message below to inquire what you need.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China