How to Improve Anodized Aluminum Disc’s Properties

There are different types of aluminum discs circle: pure aluminum discs, alloy aluminum discs, anodized aluminum discs,etc. How to improve its properties? Heat treatment is one way. Learn more.

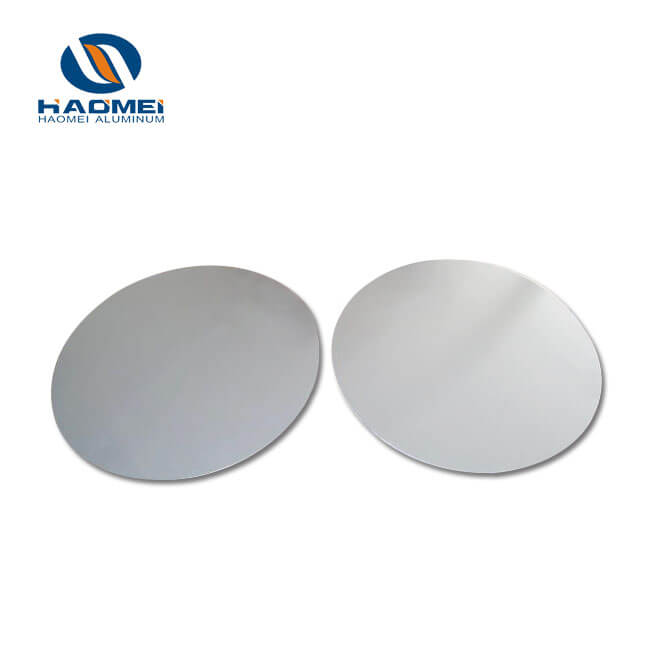

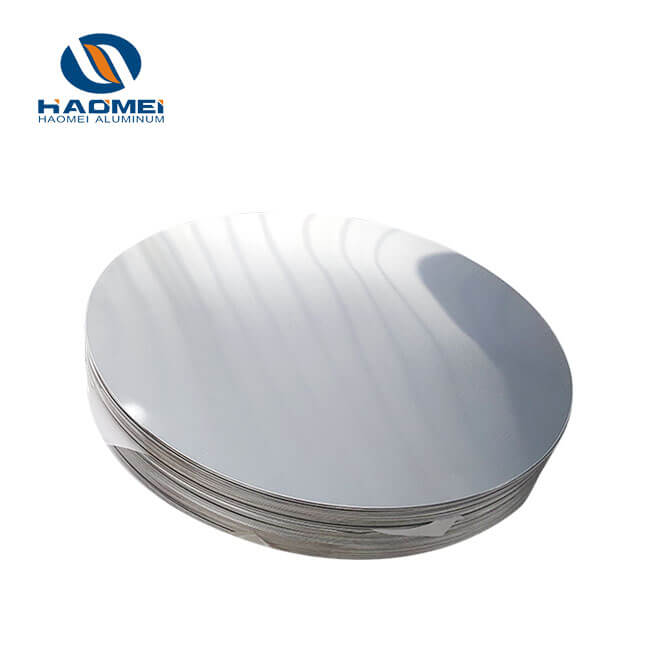

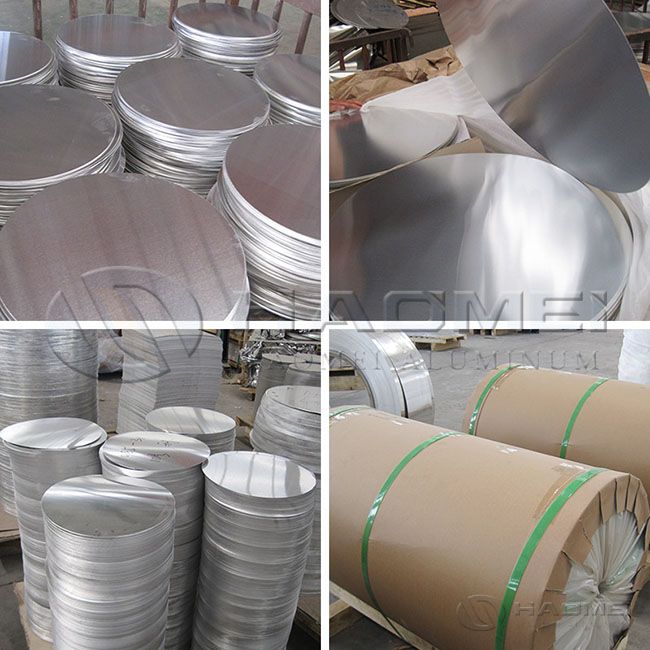

Aluminum discs are round aluminum sheets processed on the basis of aluminum plates. It is divided into pure aluminum discs, alloy aluminum discs, thin aluminum discs, medium-thick aluminum discs and anodized aluminum discs.

The thickness range of the aluminum discs circle is generally 1.0mm-5.0mm and the diameter is 30mm-200mm. The main alloys are 1060, 1100, 3003 and 5052. The tempers are H24, H22, O, H18. It is suitable for processing processes such as stretching and spinning, and can produce kitchenware, electrical appliances, LED lamp casings and other products.

1000 aluminum discs are commonly used in processing parts, deep drawing or spinning concave utensils, clock surfaces and disks, nameplates, kitchen utensils, reflective equipment, heat sinks, bottle caps, and other deep stamping products.

3000 series aluminum discs are used for processing parts that require good formability, high corrosion resistance and good weldability, such as kitchen utensils, food and chemical product processing and storage devices, tanks for transporting liquid products.

Heat treatment is an important process to improve the material properties of aluminum circles and plays a key role in the strength, hardness, and mechanical properties of aluminum discs. It is a process of heating and cooling to change the structure and properties of materials. For the aluminum circle sheet, heat treatment mainly includes aging treatment, solution treatment and stress reduction treatment.

Aging treatment refers to heating the aluminum disc to a certain temperature, maintaining it for a certain period of time and then cooling it. This allows the alloy elements in the aluminum discs to dissolve in the matrix and form a dispersed strengthening phase. These strengthening phases can effectively improve the tensile strength and hardness of aluminum discs. Commonly used aging treatment methods include natural aging and artificial aging.

Solution treatment refers to heating aluminum discs to high temperatures to dissolve the alloy elements in the aluminum matrix. The dissolved state of the alloying elements is then fixed by rapid cooling. Solution treatment can make aluminum discs have better plasticity and processability, and is suitable for aluminum discs that require subsequent deformation and processing.

Stress reduction treatment refers to heating aluminum discs that have completed other heat treatments to a certain temperature and then slowly cooling them. This can eliminate the internal stress caused by heat treatment and improve the deformation ability and fatigue resistance of the aluminum disc.

The advantages of heat treatment of aluminum circle blanks are mainly reflected in the following aspects:

1. Improve strength and hardness: Through appropriate heat treatment process, the strength and hardness of aluminum circles can be greatly improved.

2. Improve corrosion resistance: Heat treatment can eliminate oxides and other impurities on the surface of aluminum discs, and at the same time improve the corrosion resistance of aluminum wafers and extend their service life by forming a strengthening phase.

3. Improve processability: Solution treatment can make the aluminum discs have better plasticity and processability, which facilitates subsequent processing and deformation.

4. Improve thermal stability: Heat treatment can maintain stable performance of aluminum wafers in high temperature environments, delay their thermal aging rate, and increase their service life.

5. Improve the fatigue resistance: Stress reduction treatment can eliminate the internal stress caused by heat treatment, improve the fatigue resistance of the aluminum disc, and enable it to maintain stable performance under long-term high-intensity working conditions.

Haomei Aluminum has rich types and complete sizes of aluminum circles like 6 inch aluminum disc and 12 inch aluminum discs. Welcome to leave message below to inquire what you need.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China