6061 Bending Aluminum Sheet

What are the main reasons for bending and cracking of 6061 bending aluminum sheet? How to avoid the cracking? There are some professional tips like process parameters, reasonable temperature control.

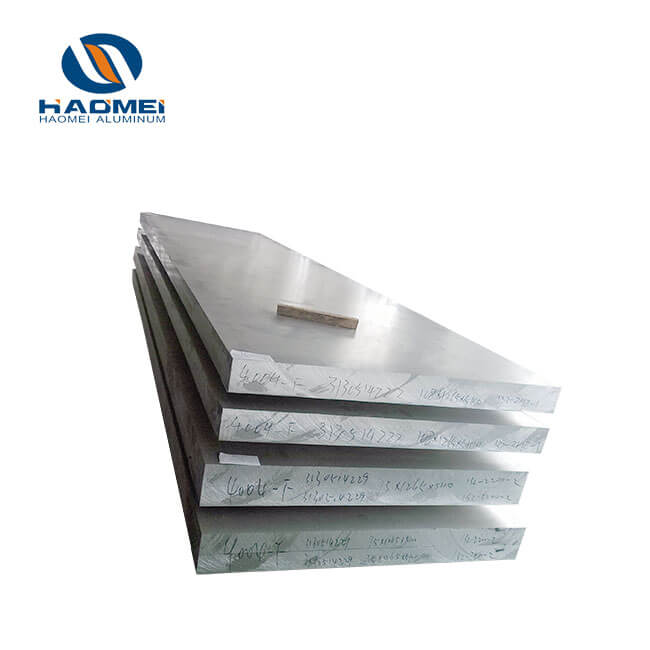

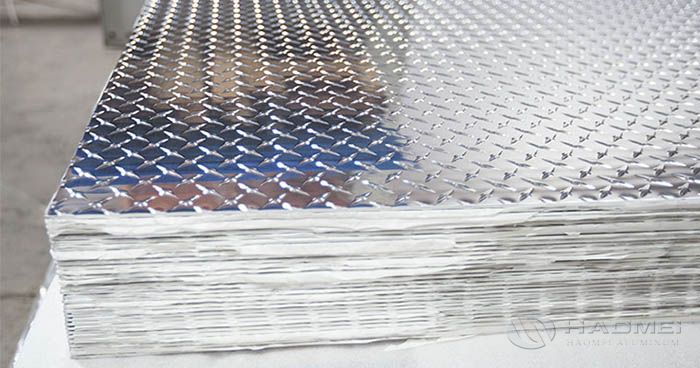

6061 bending aluminum sheet is a commonly used aluminum alloy with certain tensile strength and corrosion resistance. During the bending process, if the operation is improper or some external force is applied, it may indeed cause the aluminum plate to crack.

The main reasons for bending and cracking of 6061 aluminum plates are as follows:

1. Stress concentration: During the bending process, the aluminum plate will bend and deform, resulting in local stress concentration. If the bending radius is too small or the angle is too large, the stress will not be distributed evenly, resulting in excessive local stress and cracking of the aluminum plate.

2. Insufficient hardness: If the aluminum sheet has insufficient hardness, that is, insufficient strength, it is prone to plastic deformation when subjected to external forces, leading to cracking.

3. Cold work hardening: After cold working, the hardness of the 6061 aluminum sheet will increase, which will increase the brittleness of the aluminum plate and make it prone to cracks.

How to avoid bending and cracking of 6061 aluminum plates:

1. Appropriate process parameters: Appropriate bending radius and angle are the keys to avoid cracking. Generally speaking, the bending radius should be twice the thickness of the aluminum plate to avoid excessive concentrated stress. At the same time, the angle should gradually become larger to prevent the aluminum plate from being subjected to excessive pulling force in an instant, causing cracking.

2. Reasonable temperature control: During the bending process, the temperature of the aluminum plate also has a certain impact on preventing cracking. Reasonable temperature control can reduce the hardness of the material and reduce the risk of cracking. Depending on the specific situation, you can consider preheating before bending, or using heating equipment to locally preheat the bending area, which can help reduce the risk of stress concentration and cracking.

3. Use appropriate molds: Appropriate molds can reduce stress concentration on the aluminum plate and provide good support. Using cushioning materials such as rubber gaskets or U-shaped grooves can reduce stress concentration and reduce the risk of cracking.

4. Treatment before processing: Before processing, the 6061 aluminum sheet can undergo appropriate annealing or T6 heat treatment to improve its hardness and strength. This increases the tensile strength of the aluminum plate and reduces the risk of cracking.

Overall, these measures can reduce stress concentration and reduce the brittleness of aluminum plates, thereby effectively reducing the risk of cracking. However, specific operations still require comprehensive consideration and judgment based on actual conditions and professional knowledge. Haomei Aluminum has different sizes and tempers of 6061 aluminum plate. Welcome to leave message below to inquire Al6061 price from us.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China