5052 6061 Aluminum Alloy

AA5052 and 6061 aluminum alloys are two frequently used alloys in many fields. What are properties and uses of AA5052 and 6061 aluminum alloy? Learn more.

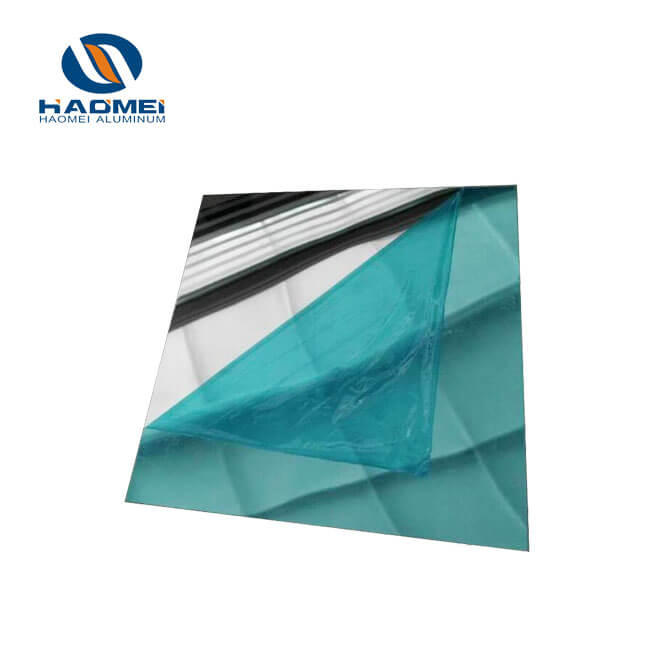

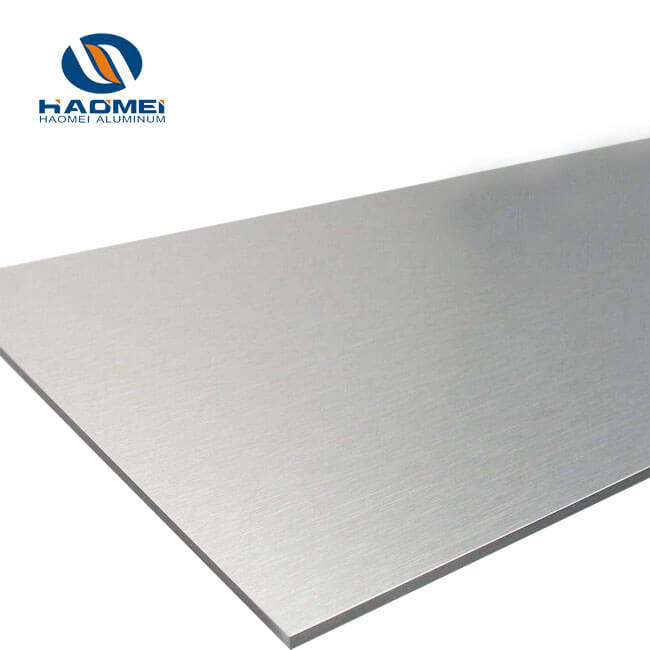

AA5052 and 6061 aluminum alloys are two frequently used alloys in many fields. 5052 aluminium sheet has multiple tempers, including but not limited to O, H32, H34, H36, h38, etc. These tempers are achieved through different heat treatment and cold working processes, and each state gives 5052 aluminum alloy different mechanical properties and applicable scenarios.

5052-O aluminum refers to the annealed state without heat treatment. In this state, the aluminum alloy material has high formability and plasticity, and is suitable for manufacturing various molded parts.

5052-H32 aluminum is a heat-treated and cold-worked state that provides moderate strength and good formability. In this state, 5052 aluminum alloy has moderate yield strength and tensile strength, and good elongation, making it suitable for a wide range of applications.

5052-H34 aluminum can achieve a balance between higher strength and good plasticity, suitable for applications with high tensile strength and corrosion resistance.

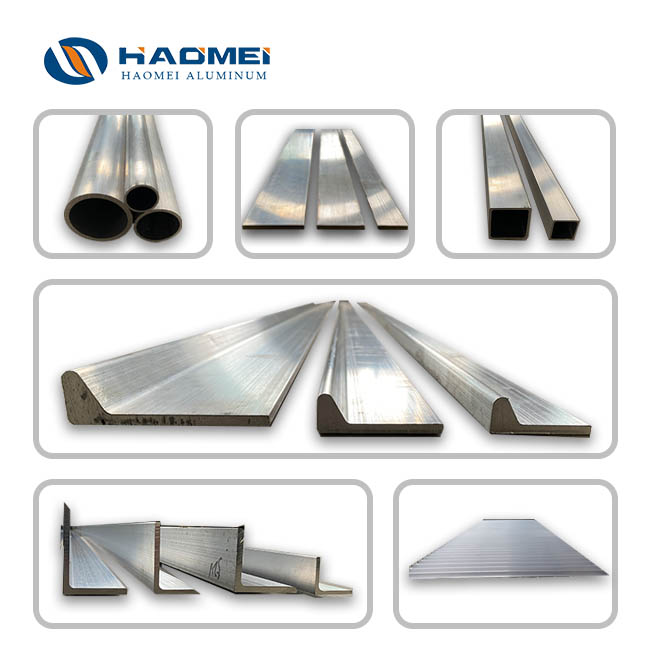

6061 aluminum is a precipitation-hardened alloy containing magnesium and silicon that can be produced by flat rolling or extrusion to produce aluminum plates, bars and rounds. 6061 aluminum is one of the most commonly used heat-treatable aluminum alloys.

6061 aluminum is light, strong, corrosion-resistant, and very practical even when the surface is worn. It is easy to cut, drill, form, tap and stamp, with excellent welding quality. The weight-to-strength ratio, corrosion resistance and weldability make 6061 aluminum the choice for a wide range of applications that require high strength, corrosion resistance and/or welding.

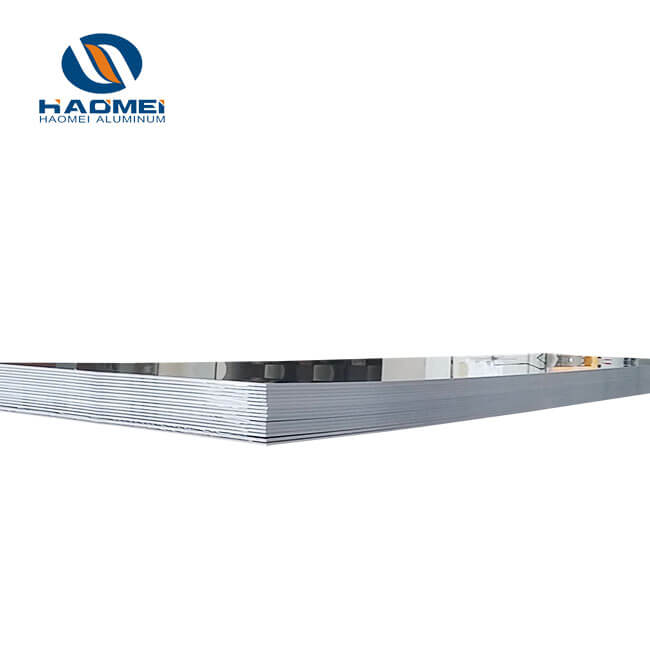

T6 temper is the most used state of 6061 Al alloy. The manufacturing process of the 6061 medium and thick plate in this temper is medium and thick plate quenching - medium and thick plate slicing - stretching machine - aging treatment - sawing machine - polishing - packaging. The whole production cycle is about 10 days. After solution heat treatment, no cold processing is required. Straightening and leveling can be performed, but it does not affect the mechanical properties.

6061-t651 is a high-quality aluminum alloy product produced by heat treatment pre-stretching process. Although its strength cannot be compared with 2XXX series or 7XXX series, it has many characteristics of magnesium and silicon alloys, such as excellent processing performance, excellent welding characteristics and electroplating properties, good corrosion resistance, high toughness and no deformation after processing, dense material without defects and easy to polish and excellent anodizing effect.

Applications

Aviation and marine | Aircraft structures,model aircraft components,yacht structures and components,docks and ramps, etc. |

Transportation | Truck bodies and frames, automobile frames, pistons, wheels, streetcar parts |

Sporting equipment | Bicycle frames and components, fly fishing reels, |

Manufacturing | Base plate, jig, machine parts, high pressure gas cylinder |

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China