What Will Aluminum Plate Thickness Affect

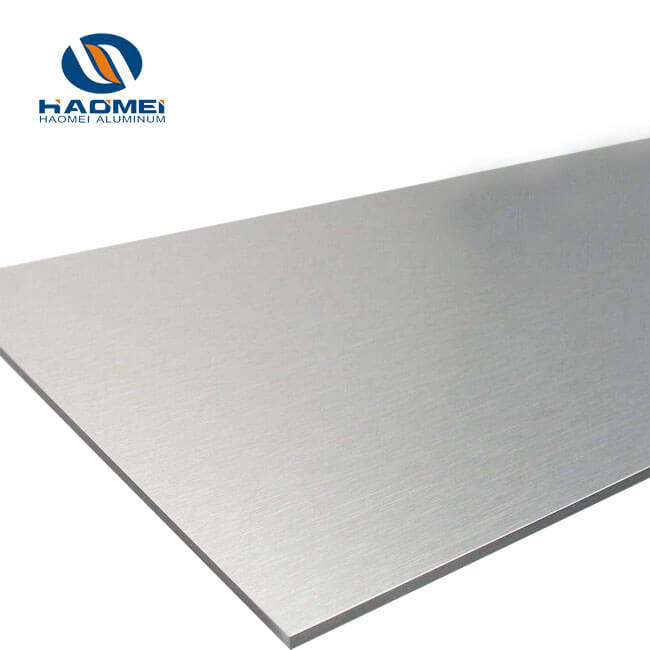

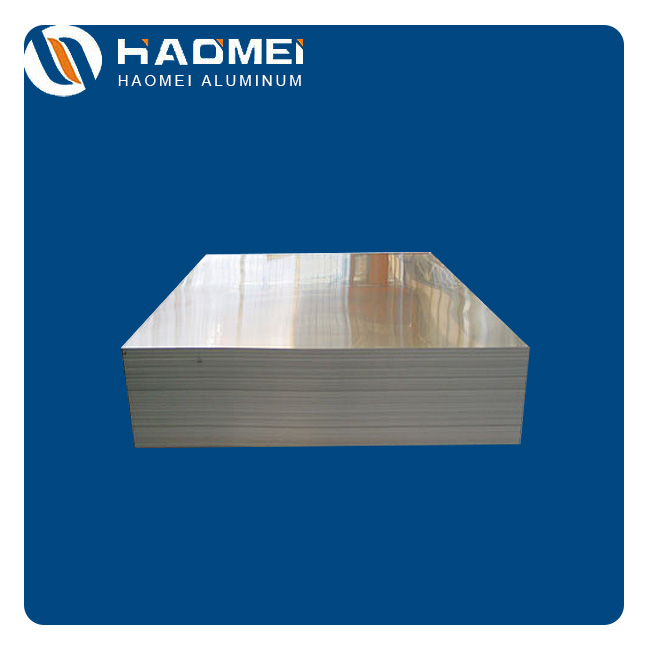

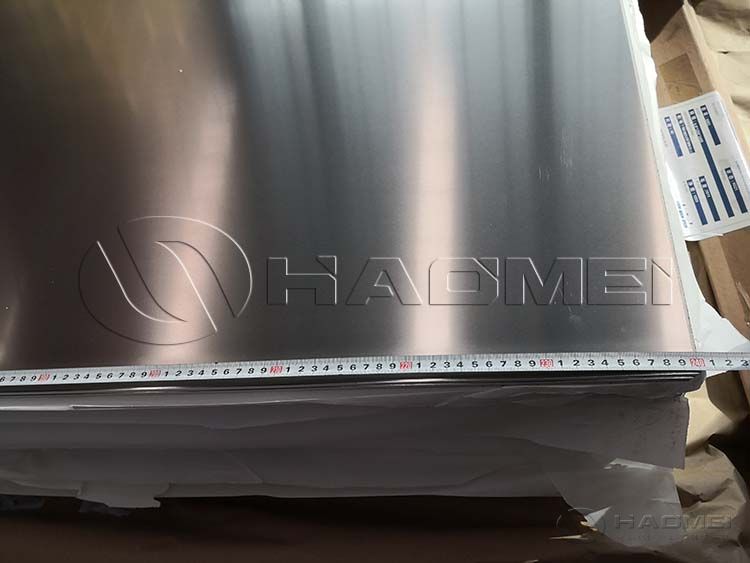

Usually we regard aluminum plates between 0.2-6.0mm as standard aluminum sheet. 4mm and 6mm aluminum sheet are two popular specifications. How will the aluminum plate thickness affect its performance? Learn more.

At present , the aluminum plate thicknesses are 0.3mm, 0.4mm, 0.5mm, 0.6mm, 0.7mm, 0.8mm, 0.9mm, 1.0mm, 1.2mm, 1.5mm, 1.8mm, 2.0mm, 2.3mm, 2.5mm, 2.8mm, 3.0mm, 3.5mm, 4.0mm, 5.0mm, 6.0mm, 7.0mm, 8.0mm, 9.0mm, 10.0mm, 12.0mm, 14.0mm, 16.0mm, 18.0mm, 20.0mm, 22.0mm, 25.0mm, 30.0mm, 35.0mm, 40.0mm, 50.0mm, 60.0mm, 70.0mm, 80.0mm.

The thickness of the aluminum plate mainly depends on the production equipment. Usually we regard aluminum plates between 0.2-6.0mm as standard aluminum sheet. 4mm and 6mm aluminum sheet are two popular specifications. Aluminum plates above 8mm can become thick aluminum plates. Aluminum plates within 6mm thickness can be directly processed from cast-rolled coils through finishing mills, while thick aluminum plates usually require hot rolling equipment to produce.

Aluminum plate thickness and price

Aluminum plate thickness is linked to price. Usually aluminum plates with a thickness of 0.8-6.0mm have the lowest price, and those that are thinner or thicker than this thickness will have a slightly higher price.

Aluminum plate thickness accuracy

Usually the thickness tolerance of aluminum plates produced by finishing mills is usually plus or minus 0.02mm or lower, while the thickness tolerance of medium-thick aluminum plates produced by hot rolling equipment is larger and is generally controlled around 0.1mm.

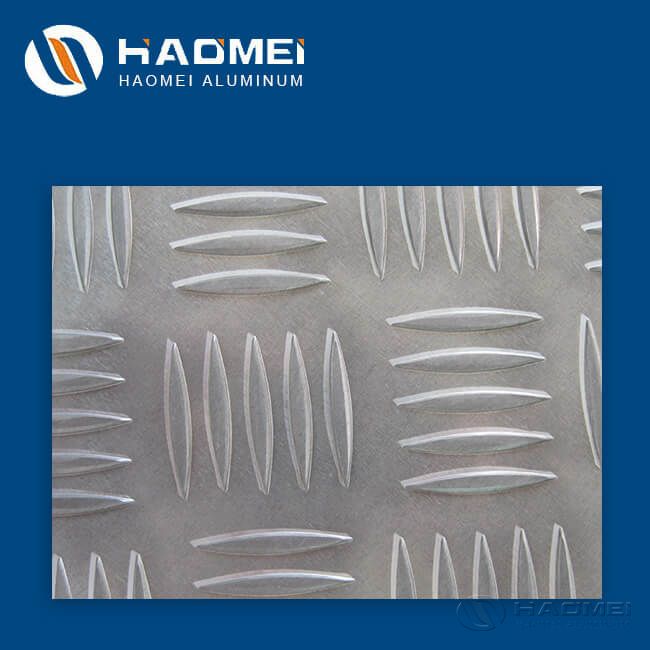

Aluminum plate thickness and its bending performance

1060 aluminum plate has high ductility and plasticity, while its strength and hardness are relatively low. These characteristics determine that the 1060 aluminum plate has high adaptability to bending processing. The thickness of 1060 aluminum plate is also one of the factors affecting its bending performance. Generally speaking, the thinner the 1060 aluminum plate, the better its bending performance. When its thickness exceeds the recommended level, the bending process will become difficult. 4mm aluminum sheet can be bent by cold bending.

When bending 1060 aluminum plates, it is also important to choose the appropriate bending process. Common bending processes include cold bending and hot bending. Cold bending is suitable for thin 1060 aluminum sheet while hot bending is suitable for thick 1060 aluminum plate.

The bending angle of the 1060 aluminum plate is also a factor that needs attention. Generally speaking, the bending angle of 1060 aluminum plates cannot exceed the elastic limit of the material, otherwise it will cause problems such as cracks and deformation.

Choosing a suitable bending mold is also an important factor affecting the bending performance of 1060 aluminum plate. Different molds have different bending radii and bending angles. Choosing the appropriate mold can effectively ensure the bending quality of 1060 aluminum plates.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China