What Is Manufacturing Process of Prepainted Aluminum Sheet

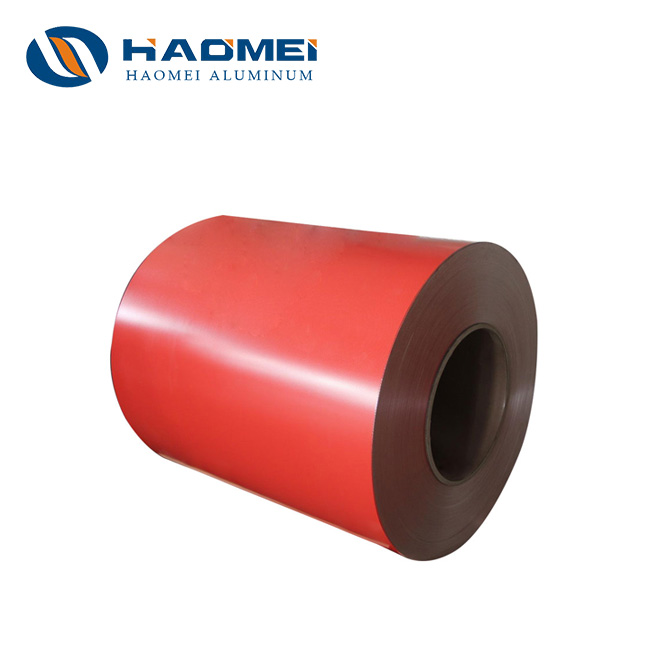

The prepainted aluminum sheet process mainly includes pre-treatment and coating. How should the aluminum trim coil manufacturers do to get the qualified finished color coated aluminum coil? Learn more.

The prepainted aluminum sheet process is to coat the surface of the aluminum coil with colored paint and then solidify it at high temperature to form a new material. The process flow of the color coated aluminum coils is mainly divided into five steps, namely plain aluminum coil, pretreatment, coating, curing treatment, and quality inspection.

1. Pretreatment

The pre-treatment serves coating process and lays the foundation for the preparation of excellent coatings. All the aluminum sheets will have some grease and lubricants remaining on the surface during the production process or absorb some impurities during transportation.

If these greases and adhesions are not removed, it will affect the coating and use of the finished products. In addition, the clean aluminum sheet surface needs to be chemically treated to form a stable conversion film, thereby improving the substrate's corrosion resistance and adhesion to the paint.

The pretreatment processes mainly includes hot alkali degreasing, hot water cleaning, chemical treatment and passivation treatment. Due to the fast line speed of the pre-coating line in hot alkali degreasing, the degreasing agent used generally has a higher concentration. Typical degreasing agents contain sodium hydroxide (NaOH), sodium carbonate (Na2Co3), water glass (Na2SiO3), phosphate, etc.

Hot water cleaning is mainly to clean the residual degreasing agent on the surface of the aluminum sheet to prevent these degreasing agents from causing secondary pollution to the substrate. The methods of use are mostly dipping and spray brushing. It is best to use water with a hardness not too high, otherwise , the minerals in the water will generate mineral spots on the surface of the substrate.

Passivation treatment is to use pressure spraying, dip coating or roller coating to form a conversion film on the surface of the substrate. Pressure spraying is generally used. In actual operation, excess passivation fluid needs to be rinsed with water. Roller coating is the best passivation construction method, with the advantages of uniform coating and no need for rinsing.

Aluminum plates generally use chromate/oxide type treatment agents, which contain chromate, chromic acid, phosphoric acid and accelerators fluoride and molybdate. This type of treatment agent must add phosphoric acid, otherwise it cannot be used for food grade painted aluminum sheet.

2. Coating

Coating is the core part of the production line. The main equipment includes a roller coater and a drying tunnel. Generally, one-side coating or two-side coating are used. According to the different directions of the coating roller and the transmission roller, it can be divided into smooth coating and reverse coating.

A roller coater is a device that uses a roller to apply paint on rolled aluminum. The most commonly used are two-roller machines and three-roller machines. The two-roller machine is mainly composed of a paint tank, a lifting roller, a coating roller, and a transmission roller.

When working, the pre-adjusted paint is pumped into the paint tank from the working pump. The lifting roller is responsible for sticking the paint in the paint tank and transferring it to the coating roller. The coating roller applies the paint to the aluminum coil in the transmission. The transmission roller is mainly responsible for the transmission of aluminum coils. During actual operation, the relative rotation speeds between the lifting roller, coating roller and transmission roller have a certain ratio.

As one of the big aluminum trim coil manufacturers in China, Haomei Aluminum has rich colors and different types for you to choose from. Welcome to leave message below to inquire what you need.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China