The Requirements for Aluminum Foil Battery

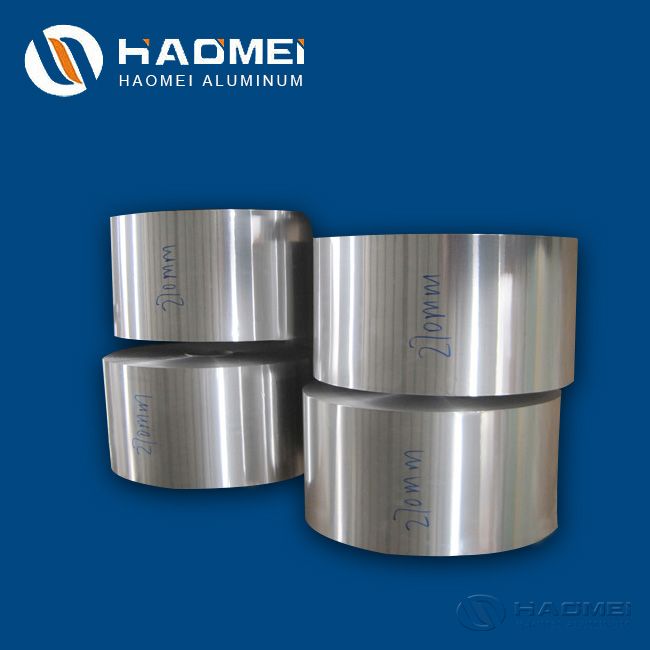

With the demand for higher performance lithium battery, the requirements for aluminum foil battery is also becoming higher. Haomei Aluminum can provide quality batter grade aluminum foil.

In recent years, the uses of lithium batteries has greatly expanded, and the demand for aluminum foil for lithium ion battery has rapidly increased. Take Samsung SDI, LG Chem, Panasonic, ATL, BYD as example. In recent years, their lithium battery production has a huge growth while the technical requirements for aluminum foil also have been greatly increased.

This has a certain stimulating effect on the domestic aluminum foil industry. Battery foil is being recognized as an independent aluminum foil variety. The recent safety accidents such as explosion and spontaneous combustion in the production or use of batteries is a warn for not only the battery industry, but also the aluminum foil. What is the requirements for aluminum foil battery?

Firstly, high cleanliness of the aluminum foil. No debris, dust, especially iron debris should be mixed into the aluminum coil, which will seriously affect the safety of the battery during the charging and discharging process.

Secondly, high requirements for the shape of aluminum foil. The uniformity of the positive electrode material coated on the surface of the aluminum foil will greatly affect the service life and endurance of the lithium battery.

The coating process is almost free of tension, which has a very strict requirements on the aluminum foil, usually below 10I.

Thirdly, high mechanical properties of aluminum foil. Under the premise of high purity, the higher the tensile strength and the elongation, the better the aluminum foil. But as we all know, the higher the aluminum purity, the lower the tensile performance. This undoubtedly brings many challenge to the development of battery aluminum foil.

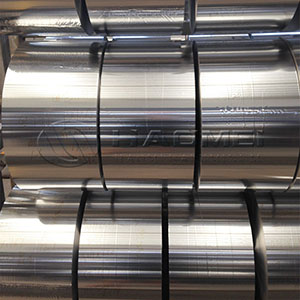

Fourthly, high requirements for thickness and pinholes. Having a thinner body is an important way to increase the capacity of lithium batteries. However, the reduction in the thickness of the aluminum foil will inevitably lead to an increase in the number of pinholes. It is another difficulty for the manufacturing of aluminium foil battery.

Fifthly, high surface requirements. The surface of the aluminum foil must not have various surface defects such as dark spots, black oil lines, and pits, having close relationship with the uniform coating of the lithium battery and the compaction process, which requires the high cleanliness of aluminum foil machines and the processing environment.

Finally, high dyne value. In order to ensure the coating quality, the dyne on the surface of the battery grade aluminum foil should be above 32 dyne, even 34 or 36 dyne.

Aluminum foil is one of the main raw materials for power batteries, and its quality management also needs to pass the TS16949 system certification. A dust-free production workshop (300,000 or even 100,000) suitable for the battery production environment has become a necessary condition. Haomei, a big aluminum foil manufacturer, has the solid power to produce quality battery aluminum foil.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China