Different Types of Aluminum Bottle Cap Materials

There are different types of aluminum bottle cap materials including aluminum plain sheet, color coated aluminum sheet, color printed aluminum sheet. The common alloys are 1060, 8011 and 3105. Learn more.

Aluminum bottle cap is made of high-quality special aluminum alloy materials and are mainly used for the packaging of wine, beverages (with or without steam) and medical and health care products, and can meet special requirements such as high-temperature cooking and sterilization.

There are different types of aluminum bottle cap materials including aluminum plain sheet, color coated aluminum sheet, color printed aluminum sheet. The common alloys are 1060, 8011 and 3105.

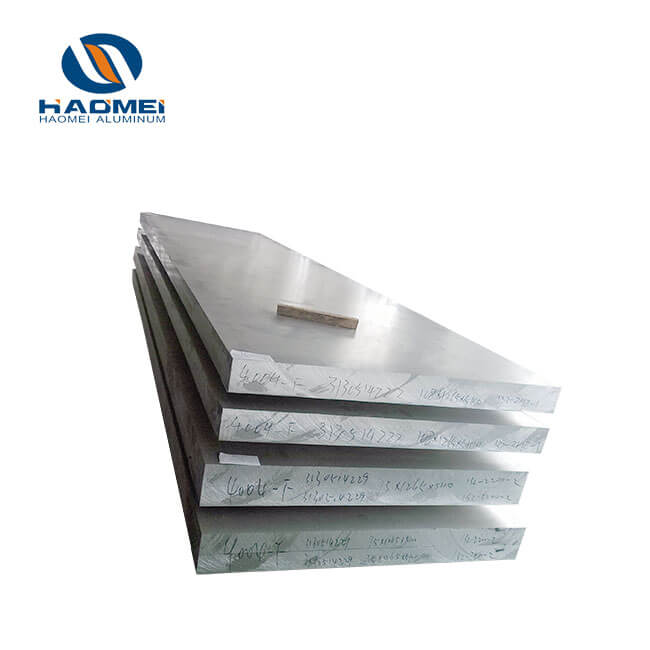

For direct casting

Alloy | Temper | Thickness (mm) | U.T.S (Mpa) | Elongation(%) |

8011 | H14,H16 | 0.15-0.28 | 125-155 | ≥2 |

3105 | H14,H16 | 0.15-0.28 | 150-200 | ≥1 |

For continuous casting

Alloy | Temper | Thickness (mm) | U.T.S (Mpa) |

8011 | H16 | 0.15~0.25 | 160~215 |

3105 | H18 | 0.15~0.25 | 220~260 |

Production line

We have complete production lines for different types of aluminum bottle cap materials: cutting production line, slitting production line, coating production line and printing production line. We have two cutting lines, two coating lines from Japan, one printing line from UK, one slitting line for making aluminum strips.

Application scope

Haomei aluminum bottle cap material can be used for the packaging beverage bottles, wine bottles, cosmetic bottles, medicine bottles, etc.

Main Alloys

As the main ROPP/PP cap material, 8011 aluminum sheet coil requires not only good deep drawing performance and low ear making rate, but also is required to have a certain strength after baking in the bottle cap making process.

3105 aluminum sheet belongs to the AL-Mn series alloy. The addition of manganese element makes it have good anti-rust performance and good electrical conductivity. Among them, the aluminum content is 98%. The 3105 aluminum alloy has 0.3% copper element, so its conductivity can reach 41%. Whether it is shear strength, tensile strength, or yield strength,the value are all very high.

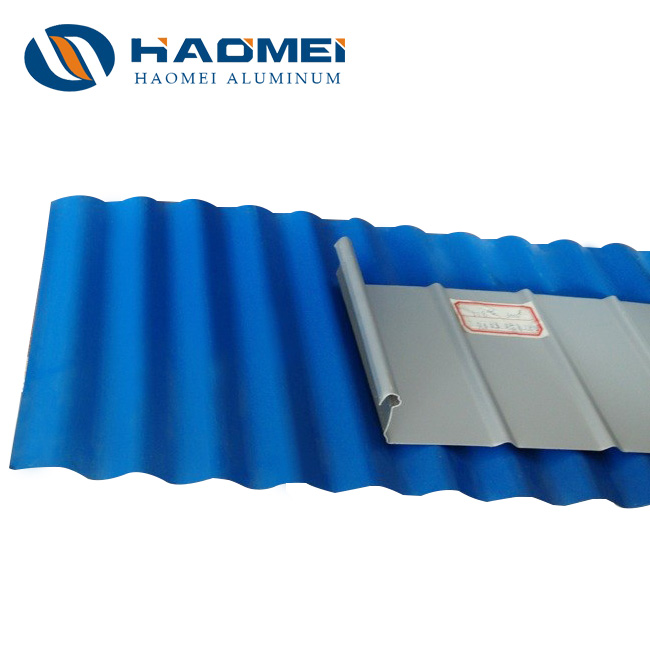

The color coated aluminum sheet is mainly pre-coated with paint or pre-coated with DOS oil on the aluminum base material, mainly using sheet coating and roller coating processes. Sheet coating means that DOS pretreatment is carried out first, and then sheet coating is carried out after cross-shear cutting; roller coating means that DOS treatment is not required, and roller coating is carried out directly on the surface of the aluminum substrate after cleaning.

Quality control

Aluminum bottle caps are mostly processed in a production line with a high degree of automation, so the requirements for the strength, elongation and dimensional deviation of the bottle cap material. Haomei aluminum foil for bottle needs to go through several test like raw materials procurement control and Pre-production test, in-production quality control and after-production inspection.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China