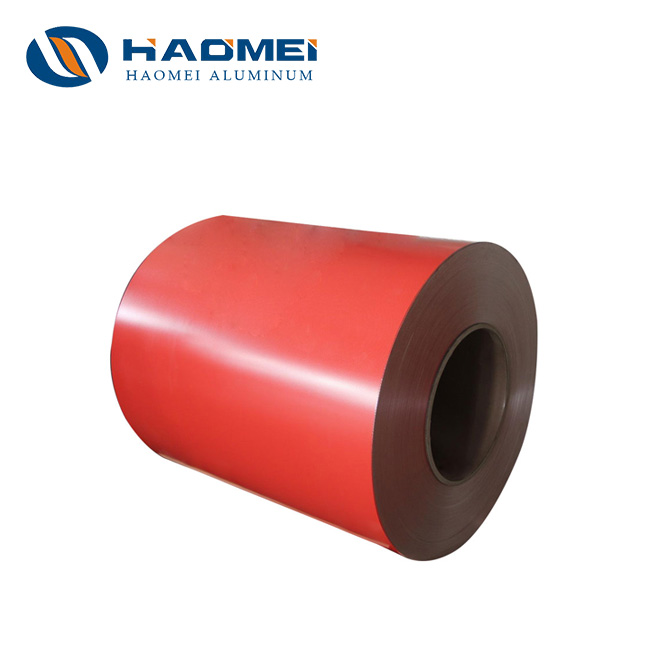

1060 Painted Aluminum Trim Coil

The painted aluminum trim coil is one of the most popular top-grade decorative materials. The two common coatings are PVDF and PE. The popular alloys are 1050 and 1060. Learn more.

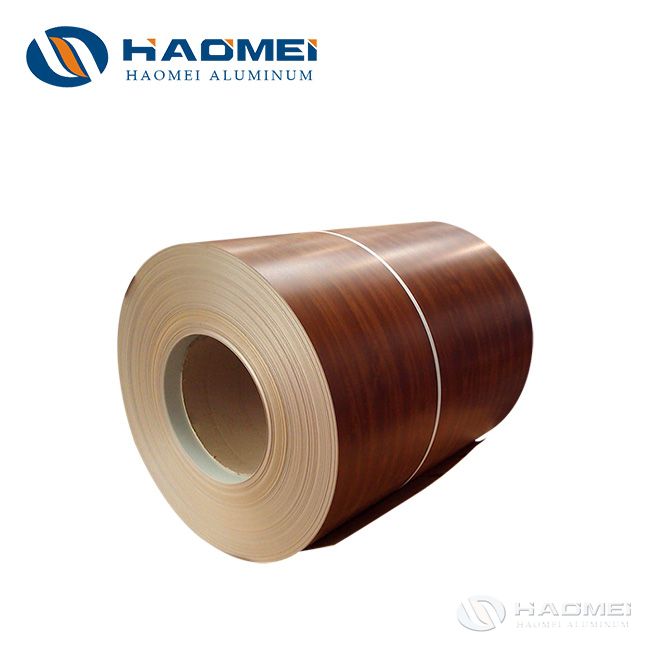

The color coated aluminum coil has become one of the most popular top-grade decorative materials. It is a green, durable and beautiful metal products. The colors of the coated aluminum coil are richer than the ordinary aluminum alloys, and various colors or patterns can be customized according to customer needs.

The painted aluminum is mainly used architectural decoration, food packaging, electronic appliances, printing, transportation and other fields. In the field of architectural decoration, the painted aluminum trim coil is mainly used in roofs, building curtain walls, interior wall decoration, ceilings, honeycomb panels, thermal insulation panels, rolling doors, blinds, etc. In the field of food packaging, color-coated aluminum is mainly used in food cans, can lids, bottle lids,etc.

The two main types of paint for aluminum trim coils are fluorocarbon (PVDF) and polyester (PE). The service life of PVDF coated aluminum coils is also very long, and it can maintain no obvious color difference for 20 years, which is 10 years longer than the color-maintaining ability of polyester color-coated aluminum coils.

Roller coating uses the coating roller as the carrier of the coating. The coating forms a wet film of a certain thickness on the surface of the coating roller. With the help of the coating roller contacting the coated object during the rotation process, the coating is applied to the surface of the aluminum coil. Roller coating is suitable for the coating of flat metal plates, especially for the high-speed coating of aluminum coils.

Color-coated aluminum coils are mainly based on 0.3mm thickness, 0.5mm thickness and 0.8mm thickness. 1050 and 1060 aluminum coil are the common alloys. The color of color-coated aluminum coils can be customized according to the RAL color card or other standard color card numbers, or can be processed by sample color matching. PVDF coated aluminum coil generally takes about 15 days.

The paint thickness of color-coated aluminum coil is a complex and important issue, which needs to be comprehensively considered according to factors such as product use, performance requirements, cost control, etc., and corresponding measures should be taken to monitor and adjust. Generally speaking, the standard paint thickness range of color-coated aluminum coil is 15-25 microns.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China