What Is the Role of Aluminum Foil in Cigarette Packaging

The production history of aluminum foil can be traced back to the early 20th century. Before 1900, people could produce small batches of aluminum foil through laborious hammering processes. Over the past 100 years, scientists have continuously improved pr

The production history of aluminum foil can be traced back to the early 20th century. Before 1900, people could produce small batches of aluminum foil through laborious hammering processes. Over the past 100 years, scientists have continuously improved production technology and equipment, making aluminum foil thinner and thinner and the output increased greatly. It has broadened the application fields of aluminum foil, from early chocolate and butter packaging paper to beverage packaging, bottle caps, cigarette packaging,etc.

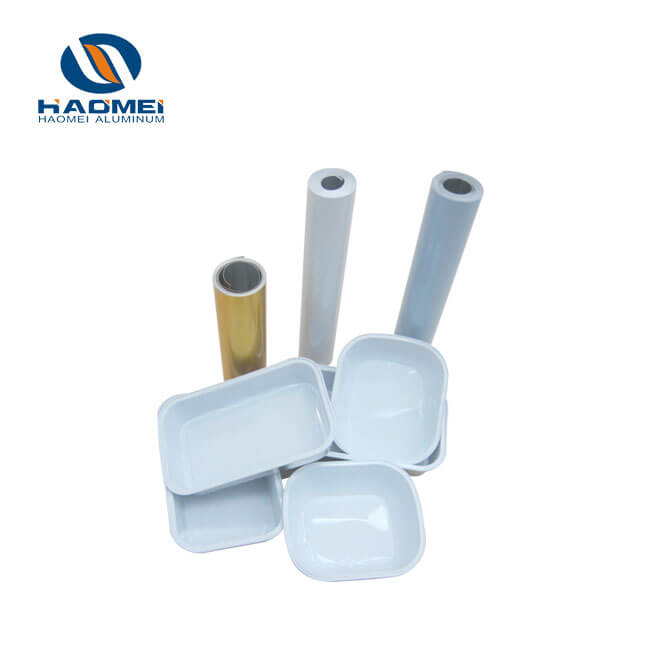

Aluminum foil for cigarette packaging has two main functions: one is to preserve the aroma, the aluminum foil paper can prevent the smell of cigarettes from dispersing and prevent the smell of cigarettes from corroding other items; the other is to prevent mildew. Aluminum foil can block moisture and effectively prevent moisture, thereby preventing cigarettes from becoming moldy in humid environments.

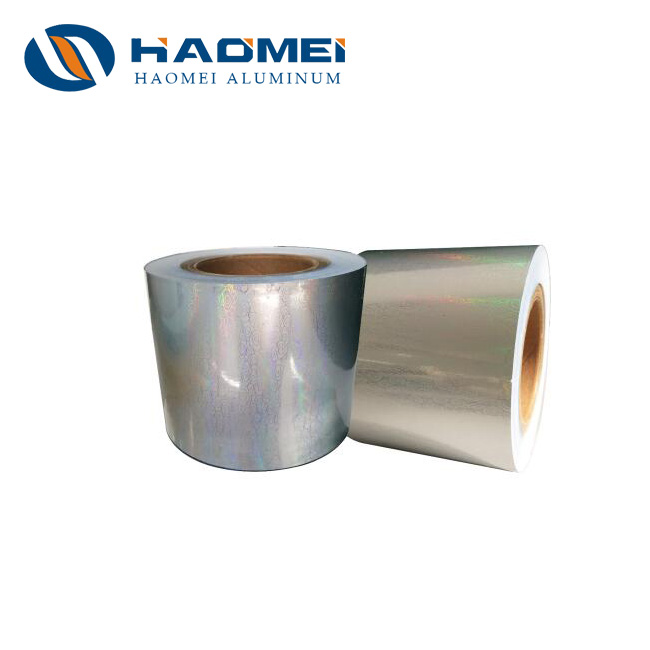

The largest amount of aluminum used in cigarette packaging is aluminum foil lining paper. Aluminum foil lining paper is a composite paper of thin paper and aluminum foil. The thickness of aluminum foil is 0.006mm to 0.007mm. Generally, 0.006mm thick aluminum foil is used.

The state is soft state, with better extensibility. The size of the aluminum foil lining paper of each pack of cigarettes is 154mm×114mm. According to the specific gravity, the aluminum foil lining paper of each pack of cigarettes accounts for about 0.284 grams.

Composite aluminum foil lining paper is a traditional type of cigarette lining paper and occupies a large market share among tobacco packaging materials. Composite aluminum foil lining paper has very good protective properties.

The unique dense arrangement of aluminum molecules can effectively block the penetration of gas and moisture, ensuring that the cigarette box hardly absorbs any aroma substances of cigarettes. Other materials such as metal-plated paper or printed paper are difficult to achieve a comparable ability to protect the aroma.

In the production process, the control of surface and performance of the aluminum foil paper for cigarette mainly includes the following points:

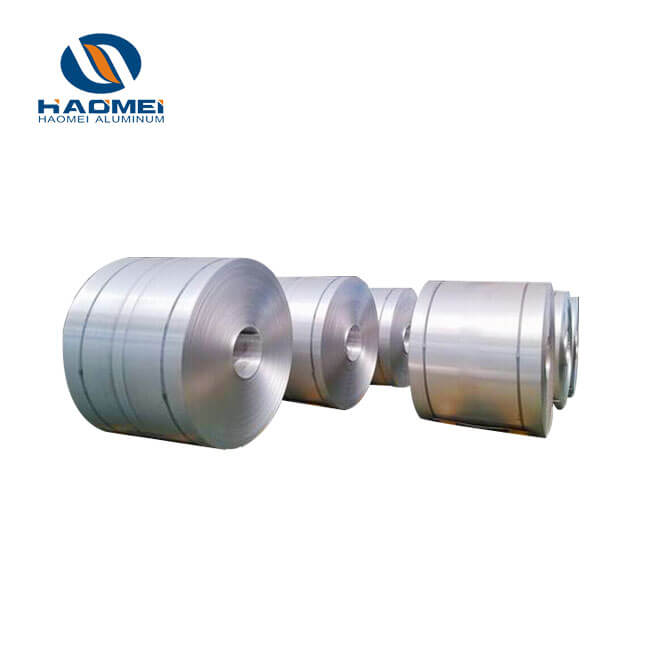

1. First of all, we must control the quality from the source and strictly inspect the aluminum blanks.

2. Then during the rolling process, the surface quality is controlled by cleaning and roughness control of the rolls, selecting rolling oil, reducing the viscosity of the rolling oil, and controlling the operating speed of the machine.

3. During the slitting process, it is necessary to ensure that the edges of the aluminum rolls are neat and there are no quality problems such as scratches.

4. In the annealing process, the annealing time and annealing temperature are controlled according to the performance requirements of the applications to ensure clean oil removal.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China