What Is Manufacturing Process of Coated Aluminum Strip

The coated aluminum strip is of beautiful appearance and longer service life. What are its manufacturing process? It includes input, surface cleaning, painting, curing, finished products. Learn more.

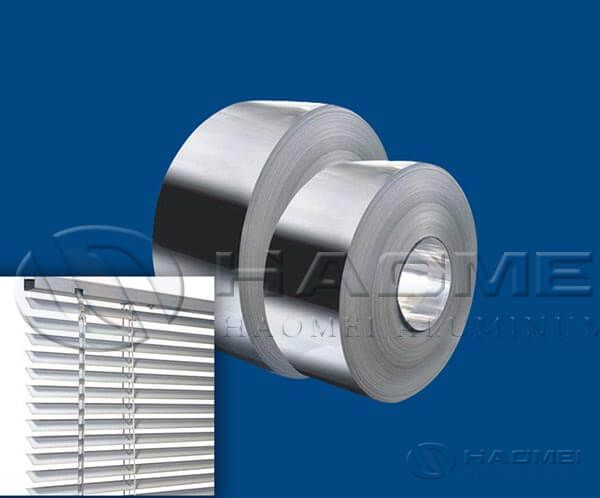

The coated aluminum strip refers to the aluminum strip with color spraying effect on its surface. The purpose of coating treatment is, firstly, to have a beautiful effect in construction, decoration, home and other fields; secondly, because of the coating process and coating thickness, which are directly related to the product quality and service life of the color coated aluminum strip.

The coating process is a key step in the production of colored aluminum strips, which directly affects the final coating quality and product durability. Therefore, the coating process is very strict. With the continuous improvement of coating equipment and the development and utilization of new coatings, the production of coated aluminum are mature. So what is the specific process of painted aluminum strip?

The general production process of coil coating has 5 steps, namely coil input, cleaning and chemical treatment, painting, curing and finished product output. The specific process layout and equipment of different manufacturers may have a little difference.

Input of aluminum coil

It is is the continuous uncoiling of the uncoiler to ensure the continuous and stable input of the coils into the production line. Some adopt a cross-rotating beam type coil carrier, and some adopt a double set of alternate decoilers before and after.

Surface cleaning and chemical treatment

The upper and lower surfaces of the aluminum coil must be cleaned and chemically pretreated, in order to ensure that the paint can be firmly attached. Pretreatment is a key process to ensure the surface quality of aluminum coil roll coating.

Through chemical cleaning agent and chemical conversion solution, in conjunction with a certain process, the oil and impurities on the surface of the aluminum coil are removed, so that a chemical conversion film is formed on the surface of the aluminum coil, which provides a good adhesion foundation for the coating and effectively ensures the adhesion quality of the coating on the surface of the aluminum strip.

Painting

There are at least two roller coaters in a production line to ensure two layers of topcoat and primer. Black aluminum strip is a popular choice.

Curing of the paint layer

The aluminum strip that has just been painted should be fixed before contacting the next roller surface to avoid mutual adhesion and damage. Generally speaking, at least two curing boxes are included.

Output of finished products

It must ensure that the speed of the production line is synchronized with the transfer of finished rolls.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China