The Manufacturing Process of aluminum strip for cosmetics

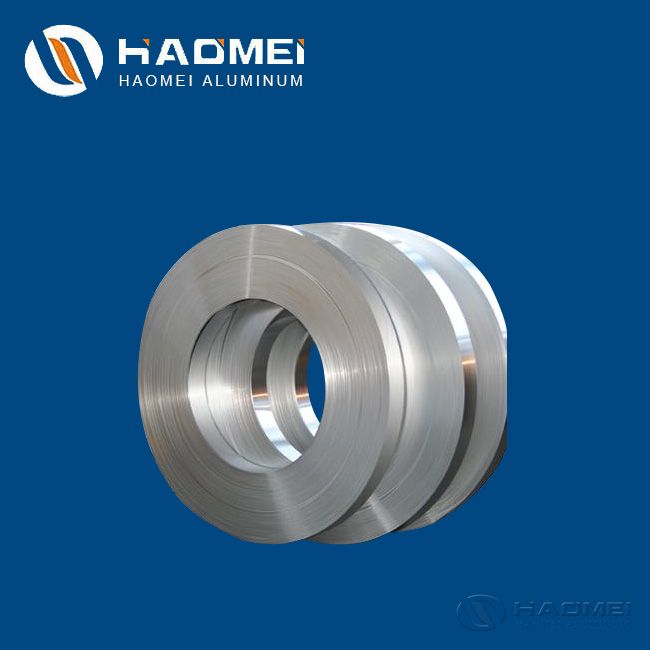

The aluminum strip for cosmetics is of better sealing, high pressure resistance, corrosion resistance,etc. The common alloys are 1070, 1050, 5005,etc. Learn more.

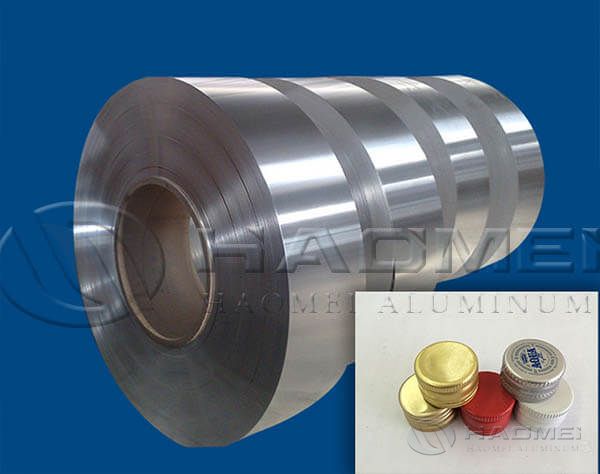

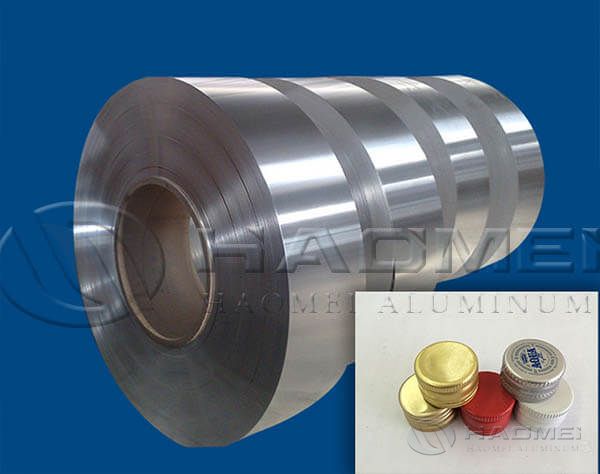

The aluminum strip for cosmetics is of better sealing, high pressure resistance, corrosion resistance, beautiful appearance and environmental protection compared with the traditional plastic or tinplate caps. At present, the aluminum strip for cosmetic cap is 1070,1050,5005,etc.,aluminum alloy strip.

In the production process, they are prone to dark color after anodizing, high ear-making rate, and easy cracking. To solve these problems, we have improved the manufacturing process. The finished aluminum strip is of smooth surface and stable property and is easy to o be stamped, which is an ideal choice for making high-end cosmetic bottle caps.

1. Prepare ingots. It contains the following elements by weight percentage: Si≤0.08%, Fe≤0.1%, Cu≤0.03%, Mn≤0.02%, Mg≤0.02%, 0.01%≤Ti≤0.02%, the rest is Al.

2. Surface milling. The milling amount is 5-30 mm per side and the amount of side milling is 4~25mm per side.

3. Homogenization heating. The furnace gas is at a constant temperature of 550℃, and the temperature is kept for 12-30 hours. The ingot discharge temperature is 480-500℃.

4. Hot rolling. The ingot with a thickness of 420-620mm is rolled by a hot rolling mill for 15-23 passes to form an aluminum coil with a thickness of 2.5~6.0mm, and the final rolling temperature is 250-285℃.

5. Cold rough rolling. After hot rolling, the aluminum coil with a thickness of 2.5-6.0mm is cold rolled into a cold rolled aluminum coil with a thickness of 0.33~2.0mm through 1-2 passes. The rolling speed is 120 -900m/min.

6. Cleaning. Use high-pressure and high-temperature water for cleaning. The high-pressure water jet pressure is 0.5- 0.8 MPa, the water temperature is 90-98℃ and the production speed is 60-300m/min. The angle between nozzle and aluminum strip production line is 45 degree.

7. Intermediate annealing. In the vacuum annealing furnace, the process of furnace gas temperature 370-500℃ and the holding time is 9-18h.

8. Finish cold rolling: The aluminum coil with a thickness of 0.33-2.0mm after intermediate annealing is rolled to 0.2-1.2mm in one pass, the roughness of the work roll is 0.008~0.02um, and the rolling speed is 120~ 900m/min.

9. Stretching, bending, straightening, cleaning and trimming.

10. Inspection: The aluminum strip roll should pass the test on the universal testing machine, cupping test machine and anodizing device.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China