What Is Deep-drawable Aluminum Strip

Deep drawing is a a complex metal forming process. One of the well known deep-drawable aluminium strips is 3004 aluminum strip. How to ensure the deep drawing ability of aluminum strip? Learn more.

Deep drawing is a a complex metal forming process that requires careful material selection to ensure success. When it comes to deep drawing, certain materials are widely used due to their unique properties. One such material is stainless steel, which is known for its excellent corrosion resistance and high strength. Another popular choice is aluminum, which is praised for its light weight and ability to withstand extreme temperatures.

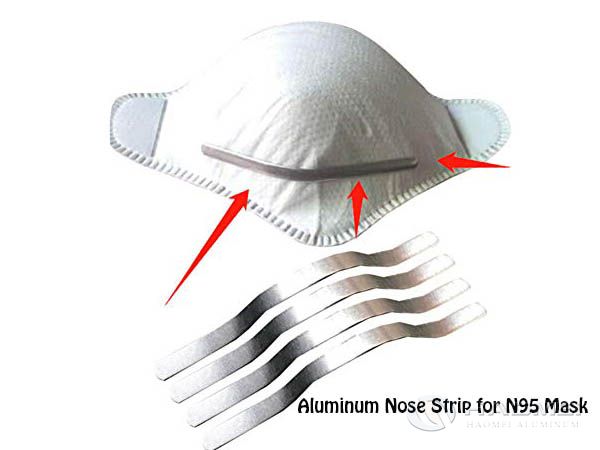

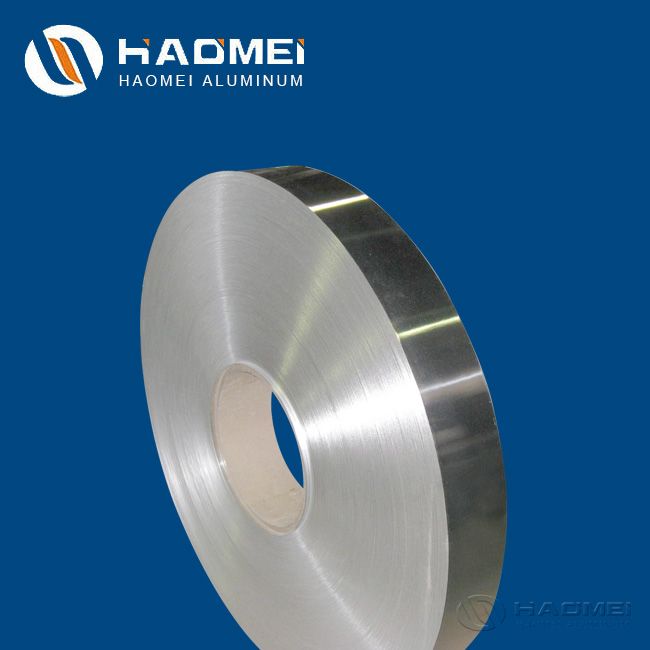

One of the well known deep-drawable aluminium strips is 3004 aluminum strip. 3104 aluminum alloy belongs to one of the Al-Mn-Mg aluminum alloys. Due to its high strength, good corrosion resistance, and good deep drawing and thinning properties, it is widely used in the production of beverage cans.\

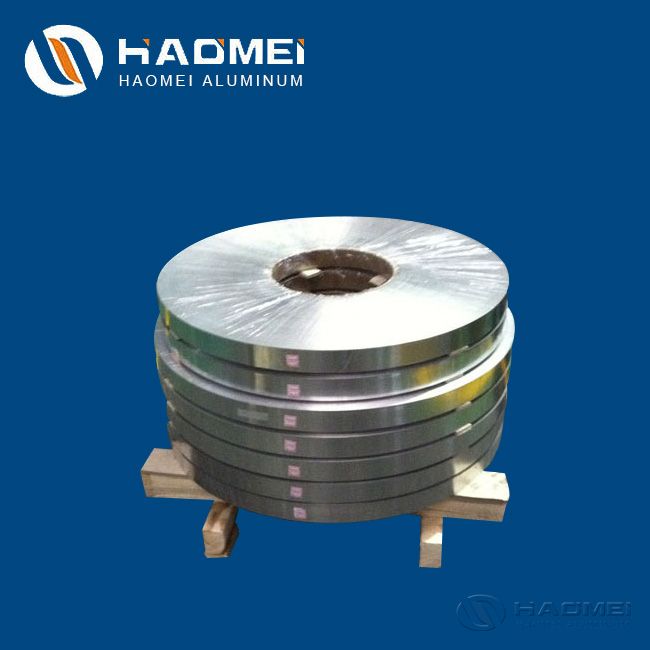

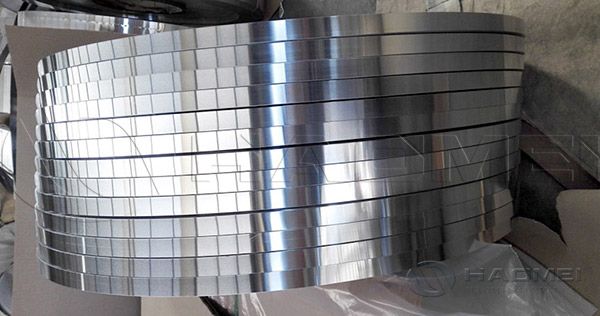

The production process of high-precision aluminum alloy strip mainly includes melting and casting, milling, homogenization and heating, hot rough rolling, hot finishing rolling, finishing, shearing, annealing and other processes.

To make aluminum strips have good deep drawing formability, fatigue resistance, corrosion resistance, excellent surface quality, high strength, sufficient plasticity, small earing rate and strict dimensional deviation, the material is required to have suitable chemical composition, excellent metallurgical quality, reasonable texture and plate shape tolerance, etc.

To achieve these requirements, effective control must be exercised over each production link of aluminum strips for sale. Composition control, aluminum melt treatment, and hot rolling process optimization are key links to improve aluminum strip quality.

The success of deep drawing is influenced by several factors that must be carefully considered. One key factor is the choice of material. Different materials have varying degrees of ductility and formability, which directly impacts the outcome of the deep drawing process.

Another important factor is the design of the die and punch. The shape and size of these tools must be precisely calculated to ensure the material flows correctly and prevent wrinkling or tearing. In addition, the lubrication used during the deep drawing process plays an important role in reducing friction and improving the overall quality of the final product. By understanding and optimizing these factors, manufacturers can achieve consistent and successful deep drawing results.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China