Aluminium for Electric Transformer

Electric transformers play a crucial role as "energy hubs" in the stable operation of power systems, and the choice of materials directly impacts their performance, efficiency, and lifespan. Aluminum alloy, with its advantages such as lightweigh

Electric transformers play a crucial role as "energy hubs" in the stable operation of power systems, and the choice of materials directly impacts their performance, efficiency, and lifespan. Aluminum alloy, with its advantages such as lightweight, corrosion resistance, and excellent electrical and thermal conductivity, has gradually become the preferred material for key components of power transformers, fundamentally helping transformers achieve their development goals of "high efficiency, miniaturization, and long life."

Applications

1. Transformer winds

Although the conductivity of aluminum alloys (such as 1050 aluminum) is slightly lower than that of pure copper (approximately 60%-65% of pure copper), optimized cross-sectional design (such as rectangular or foil windings) can compensate for this difference in conductivity and significantly reduce winding weight.

With a density of only 2.7g/cm³, aluminum alloy can reduce winding weight by approximately 60% for the same electrical conductivity. Furthermore, aluminum alloy windings offer enhanced corrosion resistance, effectively resisting the attack of trace impurities in transformer oil, and extending winding life. They are currently widely used in medium and low voltage distribution transformers.

2. Transformer oil tank and casing

Aluminum alloys (such as 5052 and 6063 series) offer excellent corrosion resistance and can withstand harsh outdoor environments without complex surface treatment. They also possess the strength required for tank structures.

Importantly, aluminum alloy tanks weigh only one-third of steel tanks, reducing not only the overall weight of the transformer but also transportation and installation costs. They have become the mainstream choice for high-end distribution transformers and prefabricated substations.

3. Transformer Heat Sinks

Aluminum alloys (such as 3003 and 6061 series) have excellent thermal conductivity (a thermal conductivity coefficient of approximately 200-230 W/(m·K), over five times that of steel), allowing them to quickly transfer heat from the oil tank to the air.

Furthermore, aluminum alloy heat sinks can be extruded into complex fin structures, increasing the heat dissipation area and further improving heat dissipation efficiency. Besides, aluminum alloy heat sinks are lightweight, corrosion-resistant, and require minimal maintenance, making them widely used in both oil-immersed and dry-type transformers.

Common supply forms

1. Aluminum Alloy Sheet

Aluminum alloy sheet is the primary raw material for transformer tanks and casings. Typical supply specifications include thicknesses of 0.8-10mm and widths of 1000-2000mm, with custom lengths available. Common alloy grades include 5052 (excellent corrosion resistance) and 6061 (a balance of strength and corrosion resistance).

2. Aluminum alloy profiles

Aluminum alloy profiles are manufactured through an extrusion process. Cross-sectional shapes can be customized according to design requirements, such as rectangular tubes, finned tubes, and special profiles. They are the core raw material for transformer heat sinks and brackets. Common alloy grades include 6063 (excellent extrusion properties, suitable for complex cross-section forming) and 3003 (excellent thermal conductivity, suitable for heat sink fins).

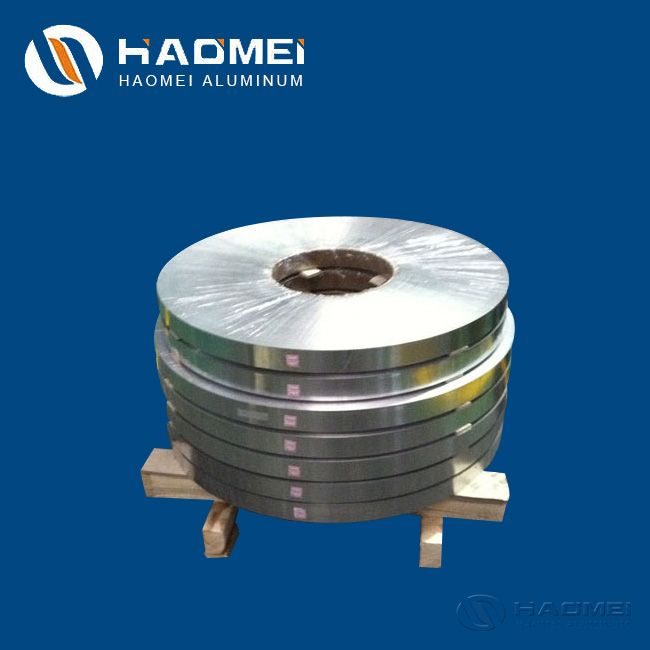

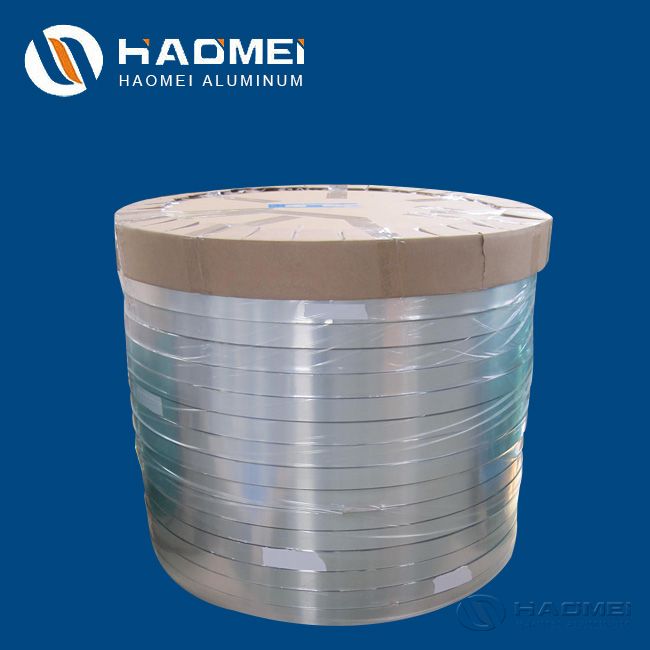

3. Aluminum strip roll

Aluminum alloy winding and leads are primarily supplied in aluminum strip roll. Aluminum alloy wire typically has a diameter of 0.5-5mm. Common alloy grades of aluminum for electric transformer include 1060 (high purity, high conductivity) and 6201 (high strength, suitable for high-current winding).

4. Aluminum alloy castings

For complex transformer components (such as high-voltage bushing flanges and tap-changer housings), aluminum alloy castings are often used due to their irregular shapes and difficult machining. Common alloy grades include ADC12 (excellent die-casting performance, suitable for complex shapes) and A356 (high strength, suitable for load-bearing components).

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China