What Are Uses of Diamond Pattern Aluminum Sheet?

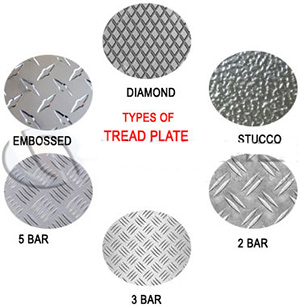

The diamond pattern aluminum sheet, 5 bar aluminum tread plate and orange peel aluminum sheet are several popular patterns. What are their uses and the manufacturing process? Learn more.

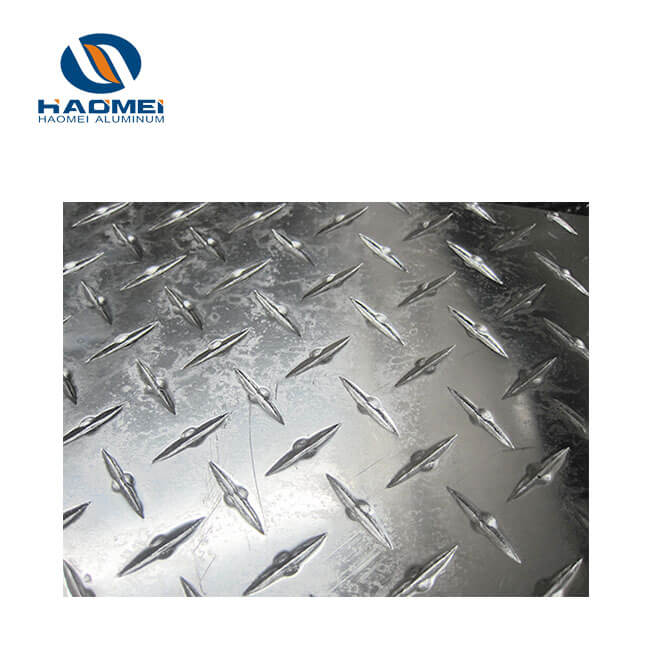

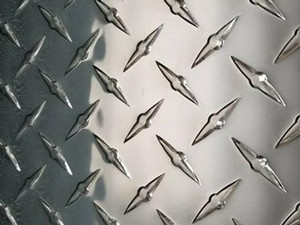

The aluminum diamond plate is mainly for anti-slip. Since the surface of the patterned aluminum plate has been pressed and rolled by an embossing machine, various patterns are formed on the surface. The diamond pattern aluminum sheet is a typical kind of embossed aluminum plate. It has a decorative effect and the thickness and strength of the aluminum plate can be enhanced after embossing.

The diamond aluminum plate can be processed into anodized aluminum tread plate. After embossing, shearing, anodizing and other processes, a high-quality embossed aluminum plate with a dense aluminum oxide protective film on the surface is formed. It is acid-resistant and corrosion-resistant, with long-lasting luster and beautiful patterns.

It is It is widely used in freezers, cold storage, refrigerators, solar heat reflectors, decorations, lamps, luggage, air conditioning ventilation ducts, interior and exterior decoration, mechanical equipment shells and other industries.

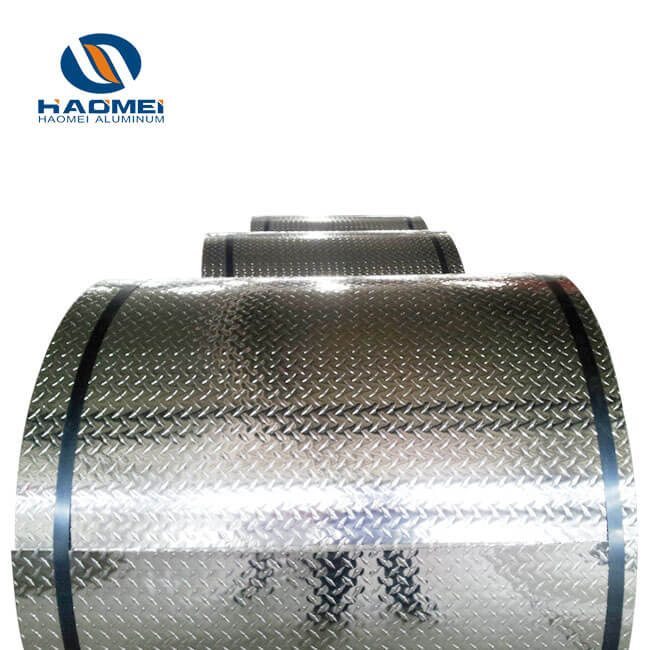

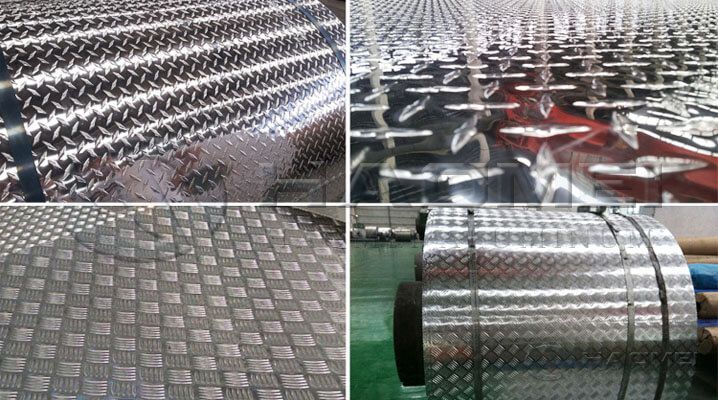

5 bar aluminum tread plate is another popular pattern. The common alloys are 1060, 3003, and 5052. It is widely used in cold storage floors, aluminum pedals, vehicle floors, trunks, service platforms, packaging pipes, screen partition frames, various suspension beams, table feet, decorative strips, door handles, wire racks, etc. Among them, the 1060-H114 aluminum alloy is a common choice for it is of cheap price and good processing performance.

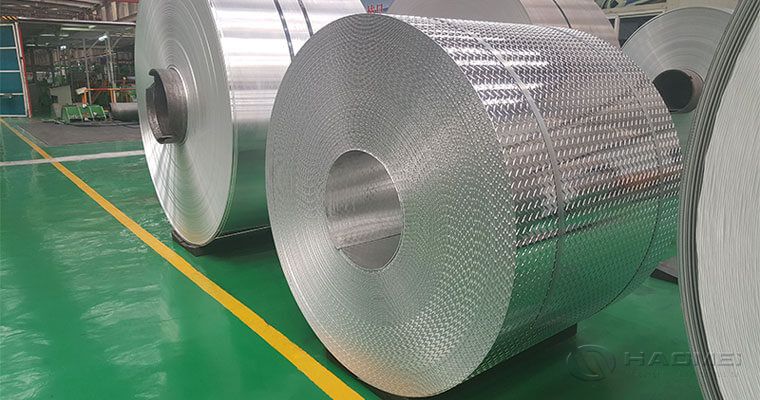

For 5 bar aluminum checker plat, the manufacturing process is like the following: it is annealed after being pressed by embossing equipment. According to the processing technology, it can be divided into continuous embossing of aluminum coil and embossing of aluminum plate after flattening. Among them, the patterned aluminum plate with continuous embossing has the same texture at the edge for the same batch, but it needs to be customized in batches around 5 tons.

Orange peel aluminum plate is made of flat aluminum plate or aluminum coil through orange peel embossing equipment. The main principle is that a pair of embossing rollers are pressed by pressure to make the aluminum plate form an uneven pattern under pressure.

Its pattern resembles cellulite. The orange peel aluminum plate is mainly used in refrigeration, heat exchange and other industries such as refrigerators, air conditioners, heat exchangers, etc. It takes advantage of the good thermal conductivity of aluminum, and the price is lower than copper. After embossing, various concave and convex patterns are formed on the surface of the orange peel, increasing the heat exchange area.

At the same time, after the orange peel aluminum checker plate is embossed, the surface reflection is reduced, so the amount of the orange peel aluminum plate used in anti-corrosion and heat preservation of pipeline equipment that has certain requirements for reflection is not small. The main thickness is between 0.3-1 mm, and is used in various machine rooms, equipment, pipelines and other equipment.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China