What Are Uses of Deep Drawn Aluminum Disc Circles

Deep drawn aluminum, a key product in the aluminum processing industry, serves as a critical substrate for the production of numerous aluminum product

Deep drawn aluminum, a key product in the aluminum processing industry, serves as a critical substrate for the production of numerous aluminum products. Its excellent ductility, corrosion resistance, and forming stability makes it crucial across multiple industries.

Core features

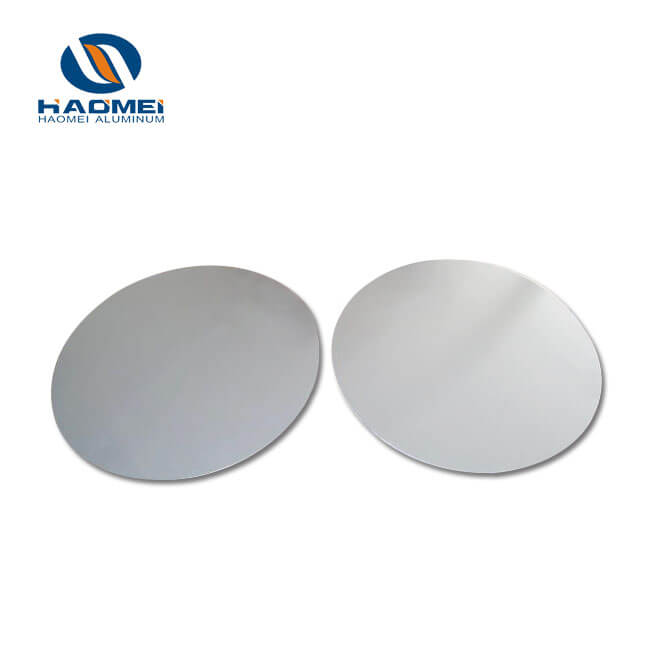

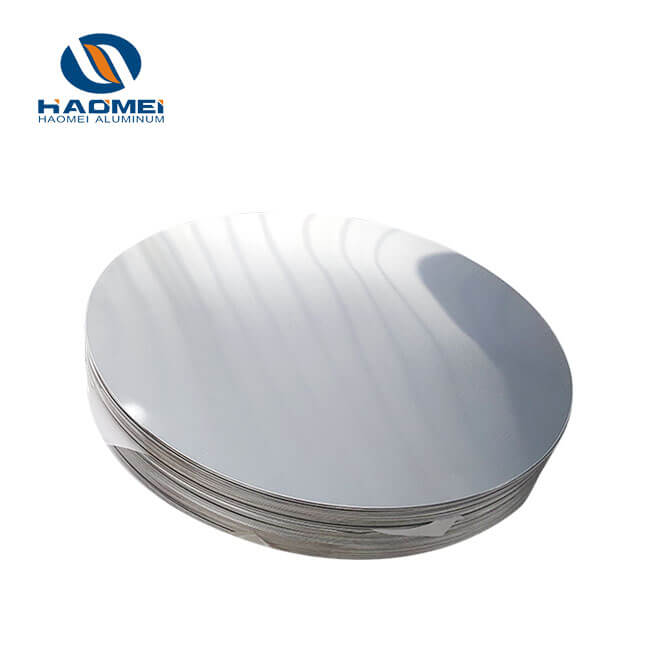

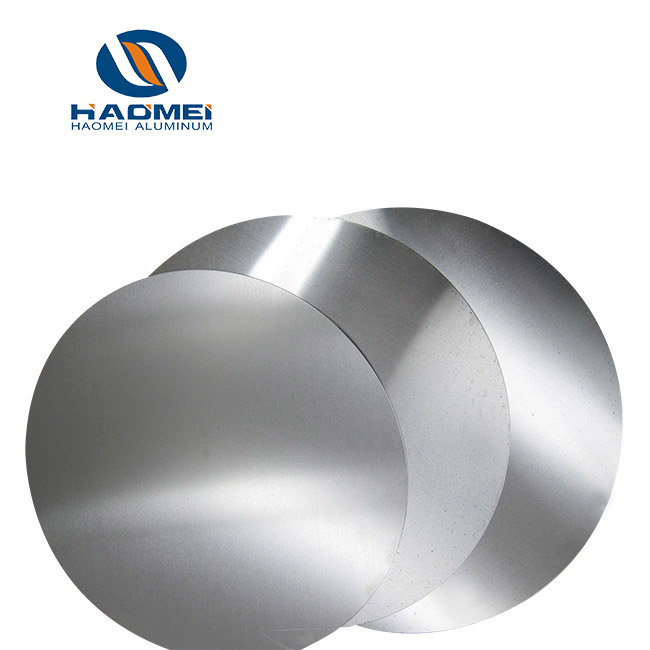

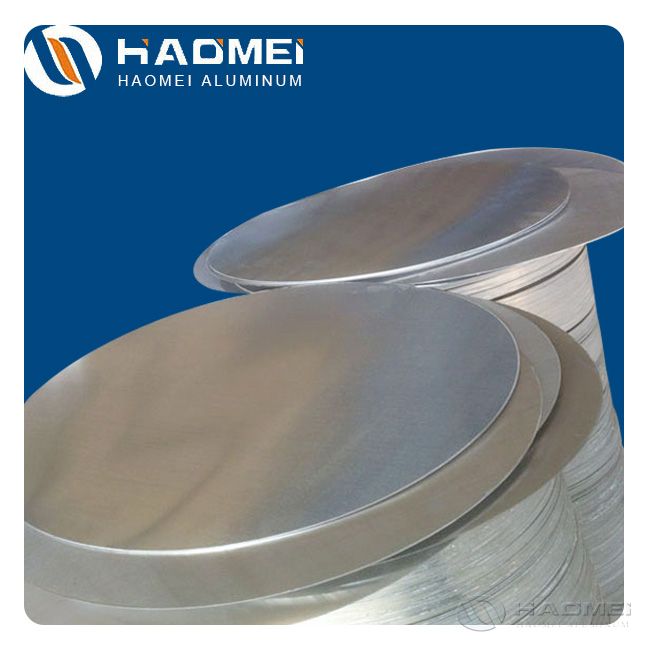

Deep-drawn aluminum discs for sale are not ordinary aluminum sheets. Instead, they are round aluminum products made from high-purity aluminum substrates (such as 1050, 1060, and 3003) through cold rolling and annealing processes. Their key advantage lies in their deep-drawn performance: they can be drawn into thin-walled parts with large depths and complex shapes using a die.

After forming, they resist cracking and maintain a smooth surface. They also retain aluminum's inherent characteristics of being lightweight, easy to process, and recyclable. These characteristics enable them to meet the customized production needs of diverse industries, making them a preferred substrate across a wide range of sectors.

Applications

Food and packaging

Deep-drawn aluminum discs are widely used in the food and packaging industries and are the primary raw material for many food packaging containers. Products such as everyday carbonated beverage cans, aluminum coffee cups, and sealed aluminum snack boxes are often made from deep-drawn aluminum discs.

Taking the common 330ml can as an example, the production process involves placing a deep-drawn aluminum circle with a diameter of approximately 120mm into a specialized mold. This disc undergoes multiple stretching processes to form a cup-shaped semi-finished product. Subsequent processes such as trimming, printing, and sealing ultimately create a pressure-resistant packaging container that can withstand external contamination.

Because food-grade deep-drawn aluminum discs meet national food safety standards and effectively block factors such as oxygen and light that affect food quality, significantly extending the shelf life of food, they have become a core substrate in the food packaging industry.

Industrial and home appliance industry

In home appliance manufacturing, deep-drawn aluminium discs circles are often used to make components such as rice cooker inner pots, electric kettle bodies, and air fryer baskets. For example, rice cooker inner pots require excellent thermal conductivity and high-temperature resistance. Deep-drawn aluminum discs not only meet these performance requirements but can also be formed into a curved structure through a precision drawing process that conforms to the heating plate, ensuring even heat transfer and improving cooking results. Furthermore, aluminum's lightweight nature reduces the overall weight of home appliances, making them easier to transport and use.

In industrial production, deep-drawn aluminum discs are commonly used to make hydraulic component housings, automotive component protective covers, and instrument housings. These applications require high forming precision and corrosion resistance. High-quality deep-drawn aluminum discs, after undergoing surface treatments such as anodizing and spray coating, effectively resist the oil and moisture erosion found in industrial environments, extending component life and ensuring stable equipment operation.

Emerging fields

In the new energy sector, some energy storage battery casings are made of deep-drawn aluminum discs. Leveraging aluminum's lightweight and excellent conductivity, they can reduce the overall weight of battery packs while ensuring heat dissipation and safety during battery operation, thereby improving the overall efficiency of energy storage systems.

In the medical device sector, deep-drawn aluminum discs are also being used in the casings of small medical devices such as blood glucose meters and blood pressure monitors. Their easy-to-clean surface meets medical hygiene standards, reducing bacterial growth and meeting the stringent hygiene and safety requirements of medical equipment.

In the cultural and creative industry, customized metal badges, commemorative coins, and other products are often made from thin, deep-drawn aluminum discs. These discs are crafted into specific shapes through stamping and engraving, achieving both aesthetics and durability, enriching the material options available for these products.

Key Points for choosing aluminum circles

In practical applications, selecting the right deep-drawn aluminum disc requires careful consideration of the following three key factors to ensure it meets specific production needs:

Material Grade: Different industries have varying performance requirements for aluminum discs, necessitating the selection of an appropriate grade. For example, 1060 grade (high purity, good ductility, and compliance with food safety requirements) is commonly used in food packaging; 3003 grade (high corrosion resistance, high strength, and suitability for industrial environments) is commonly used in industrial component manufacturing.

Thickness and Diameter: The thickness and diameter of the aluminum disc should be determined based on the dimensions of the final product and the drawing depth. Too thin can lead to cracking and deformation during the drawing process; too thick can increase processing difficulty and cost, requiring careful consideration based on the production process.

Surface Quality: High-quality deep-drawn aluminum discs should be free of defects such as scratches, impurities, and oxidation spots, as these can affect subsequent processing accuracy and product appearance. Surface quality is particularly important for applications such as food packaging and medical devices, as it directly impacts product safety and regulatory compliance, requiring strict control.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China