The Best Aluminum Foil Gauge for Different Uses

The precise selection of aluminum foil thickness directly affects product performance and cost. What is the best aluminum foil gauge needed in different uses? Learn more.

Although aluminum foil gauge is not a standard unit, some traditional industries (such as the US market) may still use "gauge" to indicate the thickness of aluminum foil. A more reliable approach is to use μm (micrometer) or mm (millimeter) directly to avoid confusion. As a multifunctional material, the precise selection of aluminum foil thickness directly affects product performance and cost.

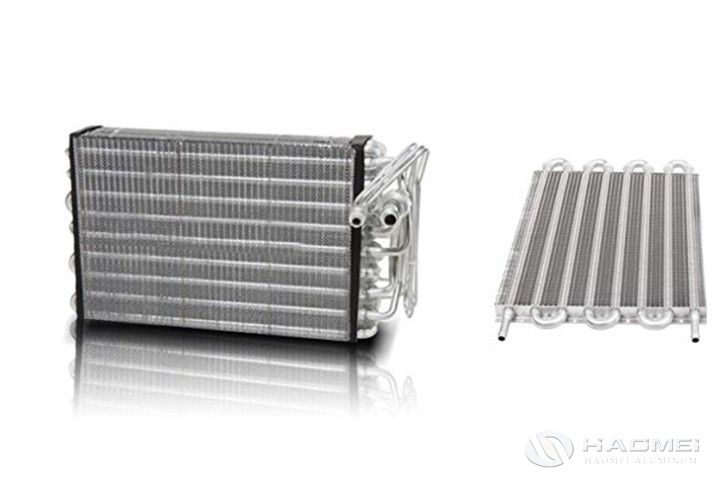

Air conditioning foil

Air conditioning foil is the core material of heat exchanger fins, and its thickness needs to take into account both thermal conductivity and formability. The current mainstream thickness is 0.09-0.15mm, and Japan's leading products have been thinned to 0.09mm. By optimizing the alloy composition (such as 8011, 3003) and coating process (double-sided coating thickness 2-6μm), it can still maintain high strength and uniformity in an extremely thin state.

Thickness selection

Thinning trend: Thinner aluminum foil can increase the number of fins per unit area and improve heat dissipation efficiency, but the plate shape control and surface quality problems during rolling need to be solved.

Coating requirements: Hydrophilic coatings (such as Type A 4-6μm) can improve condensate diversion, while hydrophobic coatings (Type B 2-3μm) are used in special scenarios to reduce frost adhesion.

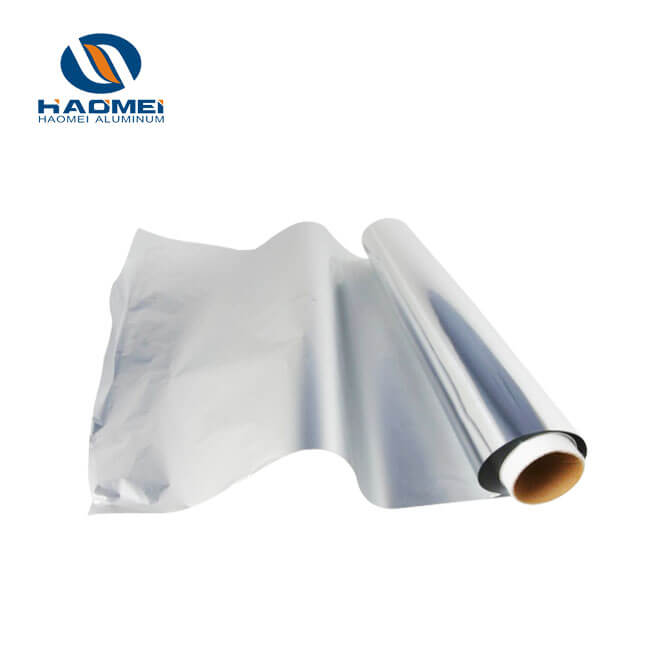

Household aluminum foil

The mainstream of household aluminum foil is 0.012-0.018mm, and common specifications include 8μm, 10μm, 16μm, etc. Its alloys are mostly 1100 or 8011, and it has excellent flexibility in the annealed state, which can meet the needs of baking, freezing, preservation and other scenarios.

Thickness selection

Basic performance: 16μm (0.016mm) is a comprehensive cost-effective choice, which can withstand high oven temperatures (200-250℃) and prevent tearing.

Special scenarios: When grilling or wrapping hard objects, you can choose 20μm (0.02mm) to enhance puncture resistance; for lightweight preservation, use 10μm (0.01mm) to reduce costs.

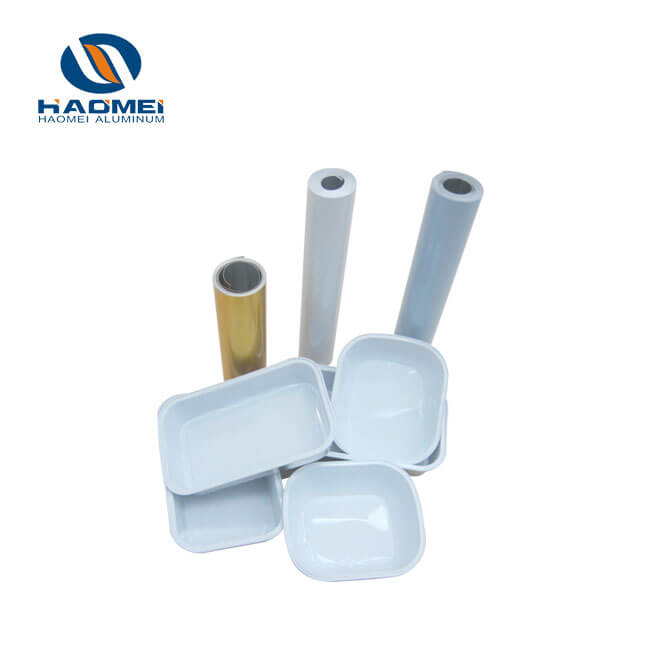

Aluminum foil for food containers

The thickness of aluminum foil for food containers ranges from 0.03-0.20mm, and is divided into two categories: wrinkled and wrinkle-free. 8011 or 3003 alloys are formed by cold stamping and can withstand temperature differences from -20℃ to 250℃, which are suitable for scenarios such as airline lunch boxes and baking containers.

Thickness selection

Wrinkle-free lunch boxes: 0.05-0.10mm for disposable tableware, which needs to take into account both formability and sealing; 0.10-0.20mm for heavy containers (such as barbecue trays) to enhance structural stability.

Chocolate aluminum foil

The best aluminum foil for chocolate packaging is 8011 aluminum foil of 0.009-0.023mm, which is moisture-proof, light-proof and tear-resistant through vacuum coating or composite process (such as combined with 25-80g/m² paper).

Thickness selection:

Single-layer aluminum foil: 0.01-0.015mm is suitable for ordinary chocolate, tightly fitting and blocking water vapor; 0.015-0.023mm is used for special-shaped or multi-layer packaging to enhance tensile resistance.

Composite structure: When aluminum foil is composited with plastic film (such as BOPP), the thickness of aluminum foil can be reduced to 0.007mm, and the overall strength and barrier properties are improved through synergy.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China