Cold Form Aluminium Foil for Pharmaceutical Packaging

Cold form foil is a better choice for the packaging of high-end medicines. 8021 and 8079 medicine aluminum foil are most chosen because of extremely high strength and good elongation. How to ensure its surface quality? Learn more.

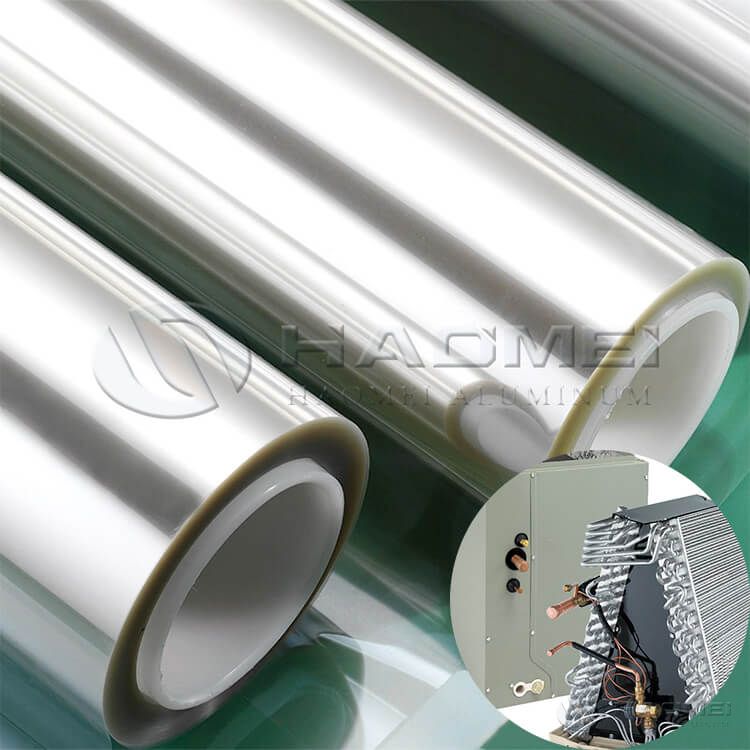

Aluminium foil is the packaging material of choice in the pharmaceutical industry. Cold form foil is a special aluminum foil that provides superior protection against heat, light, moisture and bacteria for critical pharmaceuticals.

The packaging of cold-formed blisters, like other pharmaceutical packaging, originated from the application of food packaging. In the 1970s, the earliest cold-formed blister prototypes were used to package jams. Then in the mid-1970s, Bayer united some material scientists to find a suitable packaging for aspirin tablets.

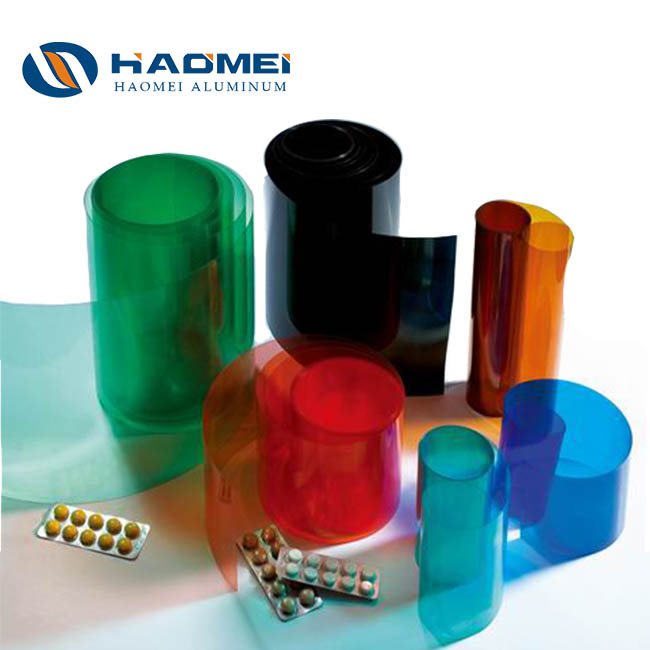

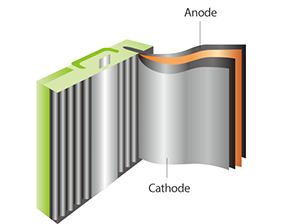

At that time, the bottom application structure they chose was PE/ALU/OPA, which was a packaging material similar to an easy-to-tear film. It was not until the end of the 1970s that the cold-formed blister evolved into our current structure OPA/ALU/PVC, and it was well heat-sealed with PTP aluminum foil without temperature.

Compared with the most common PVC material, cold forming aluminum packaging is an upgraded version of packaging, and it has all the properties of PVC. As for cold aluminum, because of the addition of the aluminum foil, the barrier effect of the material is 60 times that of PVC, and the stability of the packaged medicine is much better than that of PVC.

In addition, the sealing of cold formed aluminum and PTP aluminum foil does not require heating. For temperature-sensitive medicines, the sealing temperature of PVC will affect the quality of the packaged medicines.

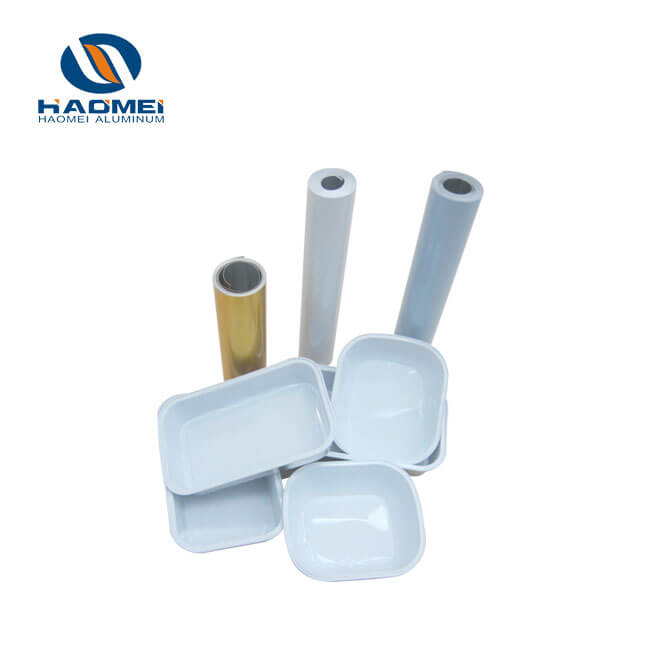

In addition to the barrier function, the intermediate aluminum foil barrier layer used in cold stamping also has functions such as strength support and stamping resistance, so it is different from the general aluminum foil for flexible packaging composites. The aluminum foil used in cold stamping is an aluminum alloy foil with extremely high strength and good elongation.

Since the cold stamping forming hard sheet needs to be stamped and formed, the thickness of the aluminum foil used is much thicker than that of the ordinary composite film. Generally, a 45μm thick aluminum foil is used. For the occasion of stamping into a shallow bubble, the thickness of the aluminum foil can be appropriately reduced to 30μm.

For the application of stamping into a particularly deep bubble (≥15mm), or the application of cold stamping hard sheet with better stiffness, the thickness of the aluminum foil can be increased appropriately to 70 μm.

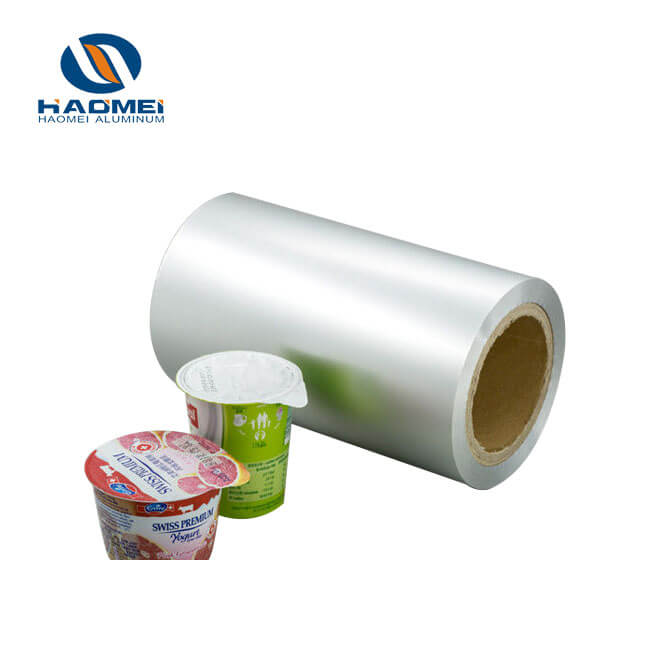

With the development of society, the quality requirements of medicine aluminum foil are getting higher and higher. Now some high-end medicines mostly use cold-formed 8021 and 8079 medicine aluminum foil. In order to obtain high-quality aluminum foil surface and dark side, the roughness of the work roll surface has an important impact on it and must be strictly controlled.

The roughness uniformity of the working rolls are controlled within 0.01μm; the paired diameter difference of the finishing rolls is still within 0.01mm; at the same time, the duplex oil adopts low-flash point, low-viscosity base oil.

It is more volatile, and the oil film formed between two layers of aluminum foil is thinner and more uniform. At this time, the lubricating performance is relatively low, which increases the friction between the two aluminum foils, so that there will be no relative sliding between the two layers of aluminum foil, and the color of the dark side will be relatively uniform, so that there will be no bright spots and no color difference on the surface.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China