How to Ensure Quality of 3 12 Inch Aluminum Disc

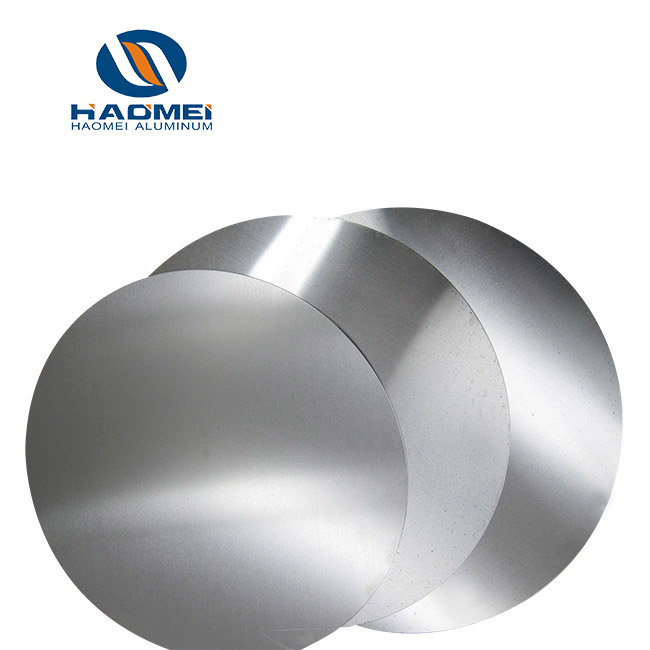

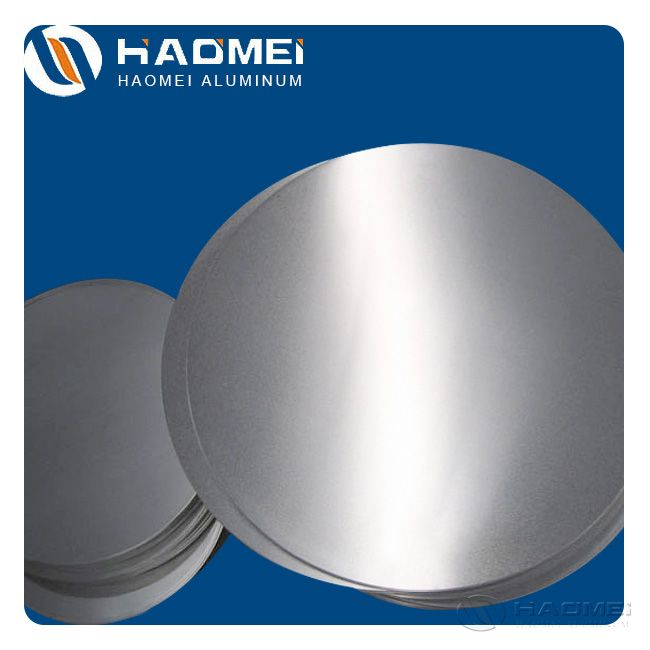

3-12 inch aluminum disc is widely used for kitchenware, cookware, road sign, sublimation, can,etc. How is aluminum discs circle produced and how to ensure its quality? Haomei Aluminum tells you.

Aluminum discs circle is widely used for kitchenware, cookware, road sign, sublimation, can,etc. The size of aluminum circle for different applications are different. The commonly use sizes are 3-12 inch aluminum disk. How is it produced and how to test if its size is accurate?

Aluminum circle production line

1. Fully automatic digital control system

As an aluminum circle manufacturer, Haomei Aluminum needs to use many types of equipment such as uncoilers, feeders, feeding trolleys, swing units, etc., and the main control systems of these machines are fully automatic digital control system.

The feature of the CNC system is that it does not require any manual operation from the unwinding of the production line to the completion of the finished product. Such a system is not only easier to control, but also can avoid hidden dangers to production safety and quality.

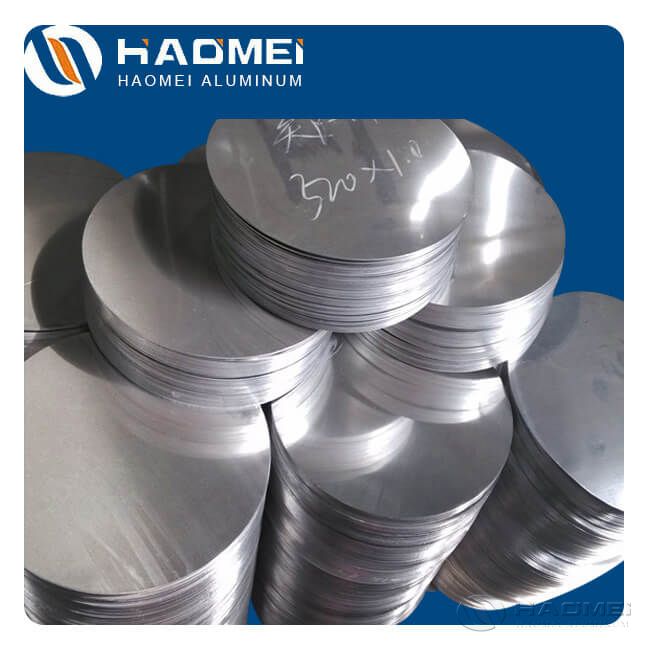

2. Professional aluminum circle production equipment

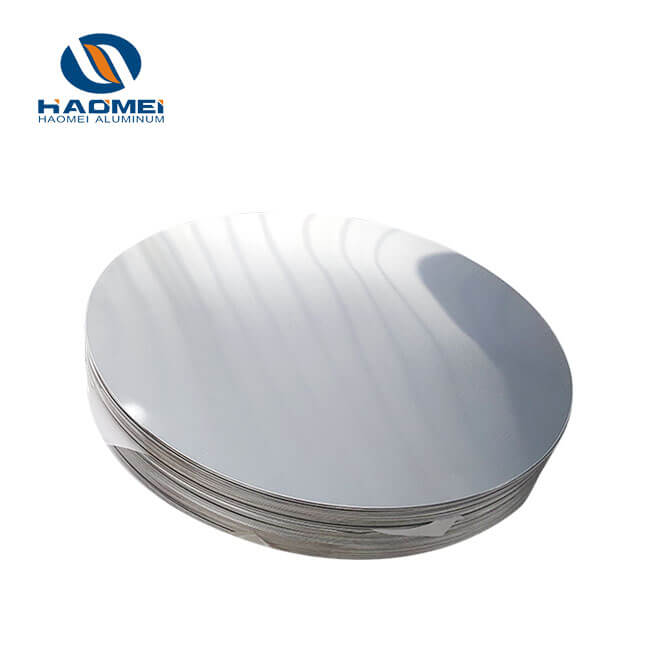

The role of these equipment is not only to produce aluminum circle with specified specifications, but also to directly produce aluminum discs in the coiling step without additional slitting and cross-cutting. There is also a modular design tool in the equipment, which can shorten the mold changeover time greatly, thus reducing the production cost.

To ensure aluminum circle production quality, Haomei Aluminum has special quality inspection positions in the process of producing aluminum discs, and the staff will also use professional tools to carefully inspect the quality of aluminum discs.

What are the regulations for aluminum circle inspection

1. The use of good measuring tools

When inspecting the aluminum disc, the staff needs to use professional measuring tools. Since the aluminum disc is very thin, if there is any defect in the measuring tool, the measurement result will be affected to a certain extent.

Therefore, in order to ensure accurate detection of the accuracy of aluminum round plate, the staff must pay attention to protecting the measurement tools. Not only can the detection tools not be stored near corrosive gases, but they cannot be disassembled by non-measurement protection personnel.

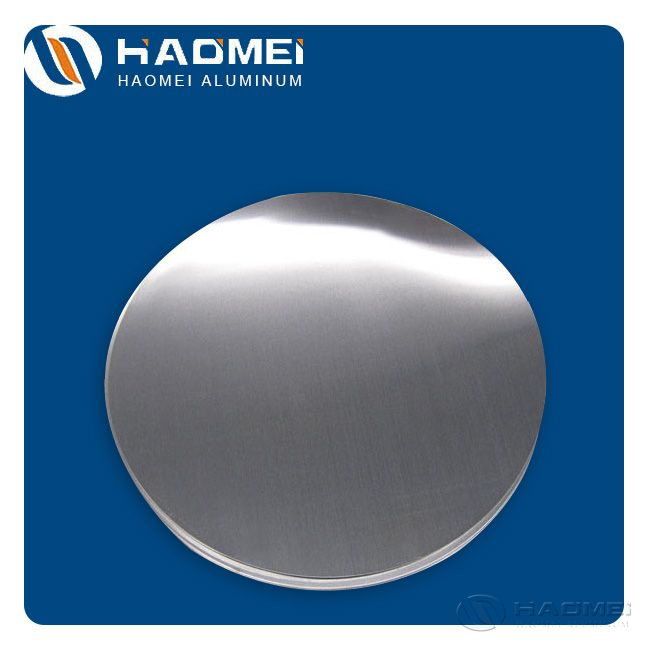

2. Pay attention to remove the surface burr first

When testing the accuracy of aluminum discs during the production process, if there are burrs on the surface of the aluminum discs, it will affect the accuracy testing. Then, in order to avoid affecting the quality detection accuracy of the aluminum discs, the burrs of 3 inch aluminum circle should be removed first.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China