How to Control Quality of White Aluminum Trim Coil

Haomei Aluminum has rich trim coil colors, including dark, white, brown, bronze, green, gray. Its popular sizes are 10 inch, 14 inch and 24 inch and 36 inch. Learn more.

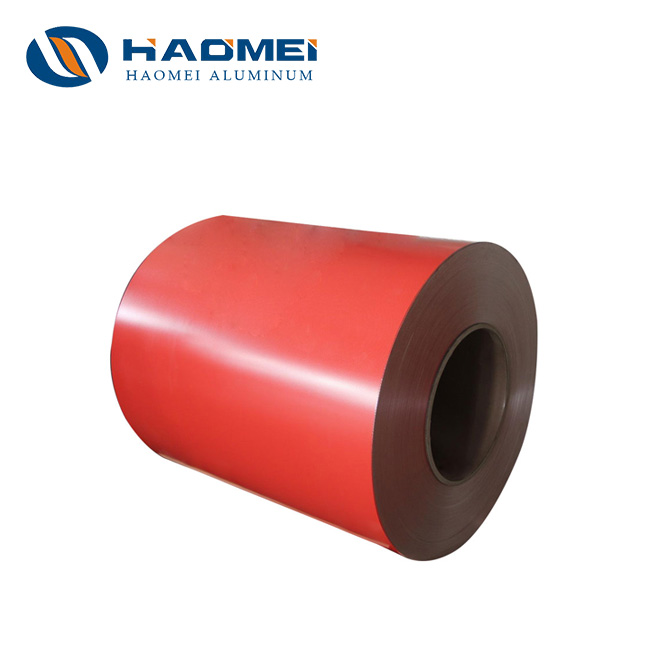

Haomei aluminum trim coil is used to weatherproof and beautify outside building surfaces. It has rich trim coil colors, including dark, white, brown, bronze, green, gray. The common sizes are 10 inch, 14 inch and 24 inch and 36 inch. To ensure its quality, we need to pay attention to the following aspects:

1. The painting quality is inseparable from the blending of the pigments. Only when the paint is properly blended and mixed evenly, can the color of the aluminum trim coil be smooth and beautiful. Therefore, it is necessary to ensure that the coating has no agglomeration and moderate viscosity.

2. The defoamer must be added in the process of blending the paint, thus reducing the foam generated by the machine during the mixing process. The addition amount should be reasonable and suitable. The mixed paint should be allowed to stand for a period of time before being used on the roller.

3. When we choose plain aluminum coil, it is necessary to choose the aluminum coil with high flatness and intact shape. In view of the scratches that may occur during the processing, preventive measures must be taken to ensure that the whole process is free from scratches.

4. The defective rollers are forbidden to use. And pay attention to the changes in paint consumption. If there is a large change in paint consumption, it may be that the pressure between the coating roller and the fixing roller has changed, and the pressure between the rollers must be readjusted.

5. The coating process is a key operation link for the white aluminum trim coil. It is it is also a decisive process that determines the aluminum trim coil quality. For the coatings of the trim coil, the mixing ratio should be strictly adjusted according to the given ratio.

6. Before painting, it is necessary to make the paint used evenly spread on the coating roller as much as possible, and to ensure the flatness of the aluminum coil. Only when the pressure of the coating roller is uniform, can the thickness of the terminal coating film be uniform and consistent.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China