How to Choose Aluminum Circle Sheet

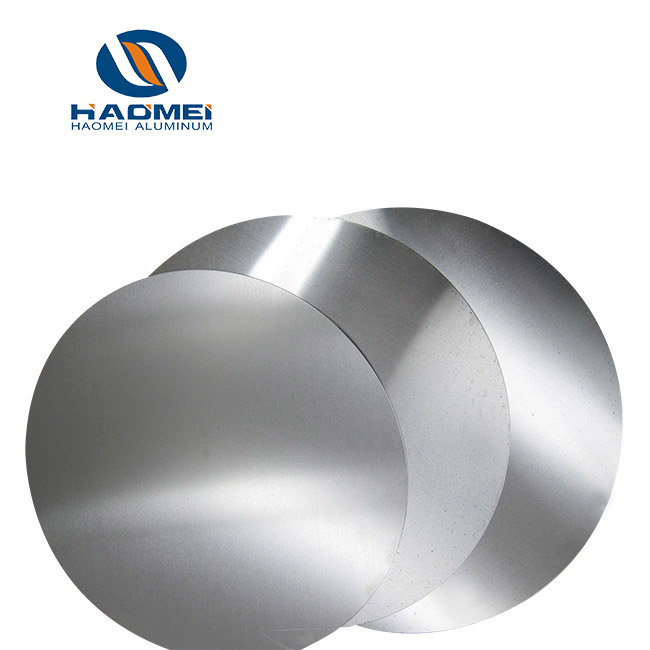

In terms of aluminum circles itself, how should you choose a aluminum discs circle? The choice involves physical and chemical properties, composition, processing performance, aluminum circle sizes, etc. Learn more.

In terms of aluminum circles itself, how should you choose a aluminum discs circle?

1. Physical and chemical properties

Aluminum circle sheet should have good thermal conductivity, electrical conductivity and good corrosion resistance. At the same time, related properties such as the strength, hardness and toughness of the material also need to be considered. Different processing techniques require different performance requirements for aluminum discs.

2. Purity and composition

Generally speaking, aluminum discs with higher purity have better electrical and thermal conductivity. High-purity aluminum discs have good corrosion resistance and are suitable for use in corrosive environments. At the same time, attention should also be paid to the additional elements of aluminum discs, such as magnesium, manganese, etc. Their content has a certain impact on the performance of the material.

3. Strength and toughness

When selecting a material, its balance of strength and toughness needs to be considered. Generally speaking, there is a certain antagonistic relationship between strength and toughness, that is, the stronger the material, the relatively poor toughness. In practical applications, it is necessary to select the appropriate aluminum round sheet according to the specific situation to meet the use requirements after processing.

4. Processing performance

Processing properties include plasticity, weldability, machinability, etc. During the processing, aluminum discs need to undergo shearing, stamping, welding and other processes. Therefore, aluminum circles with good processing properties need to be selected to ensure the smooth progress of the process.

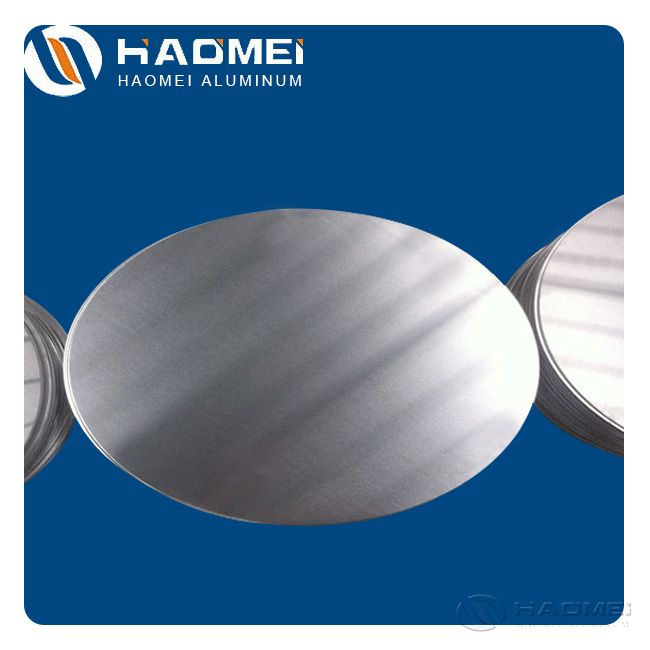

5. Surface treatment

Surface treatment can improve the corrosion resistance, oxidation resistance and surface finish of aluminum discs. Common surface treatment methods include anodizing, electroplating, spraying, etc. When selecting materials, you need to consider the need for surface treatment and choose the corresponding material.

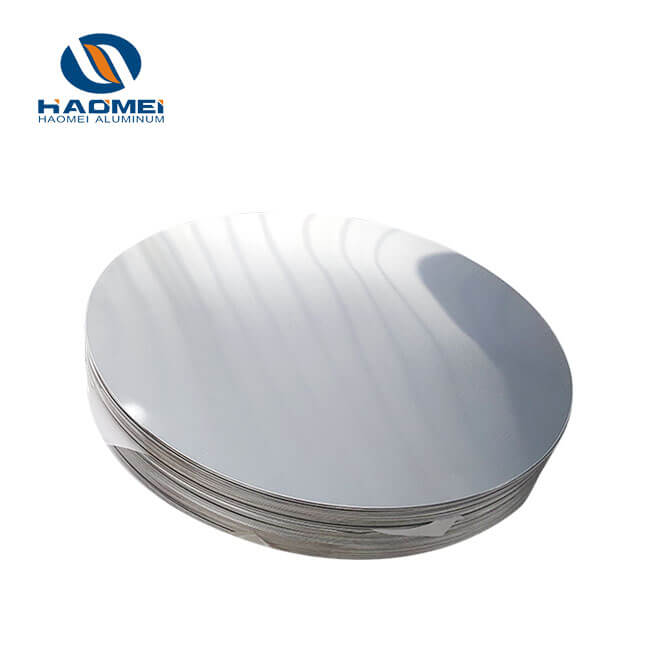

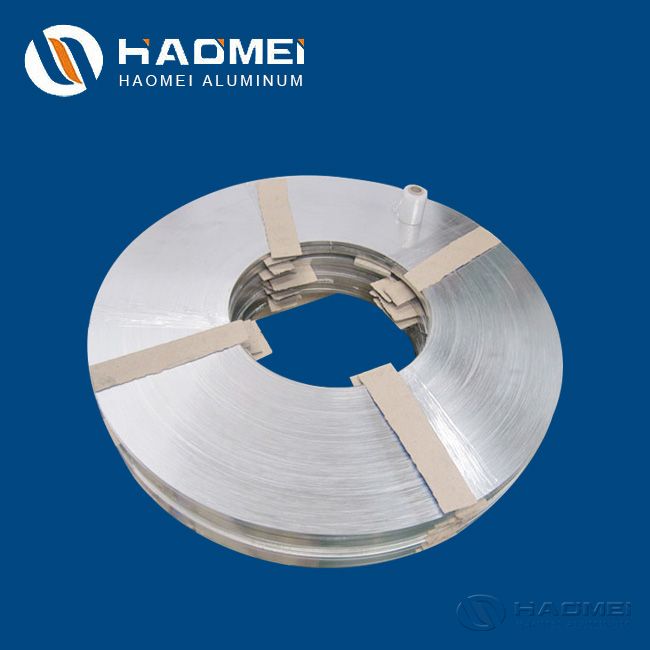

6. Aluminum round blanks thickness and size

The thickness selection of aluminum discs is determined based on specific usage requirements. The first thing to consider is the mechanical performance requirements of aluminum wafers. Aluminum discs of different thicknesses have different mechanical properties such as load-bearing capacity and strength.

If the application needs to bear larger loads or has higher tensile strength requirements, thicker aluminum discs will be selected to meet these requirements. If it is for decoration or thermal conduction, then you can choose thinner aluminum discs.

For road signs, large size aluminum circles are often chosen like 24 aluminum disc. For cookware or small household appliances, small size aluminum disc circles are chosen.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China