Cold Forming Blister Foil Pharmaceutical Packaging

The cold forming blister foil pharmaceutical packaging has high requirements for the strength and thickness. 8021 and 8079 blister foil are two pharmaceutical aluminium foil for cold forming.

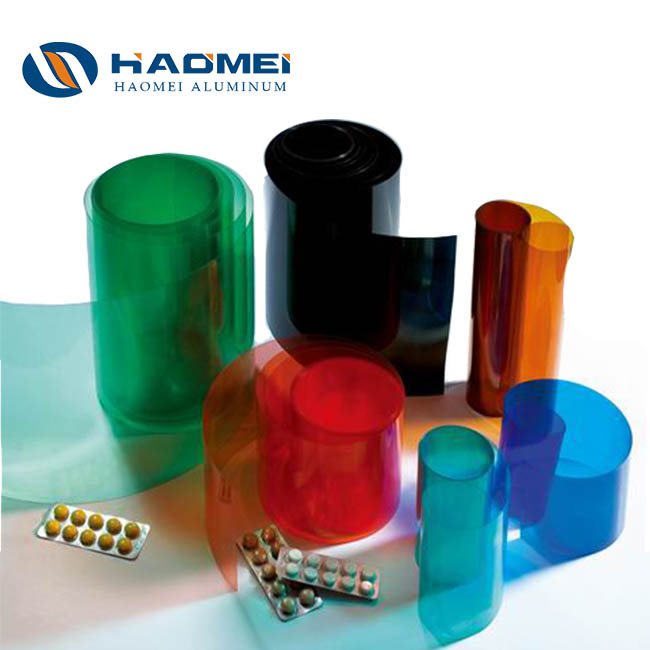

The blister packaging of medicines consists of aluminum foil and PVC rigid sheet. However, with the continuous development of the pharmaceutical industry, this traditional packaging method has exposed its shortcomings: due to the limited barrier properties of PVC rigid sheets, it is difficult to ensure that the quality of the medicines will not change during their service life.

In response to the limited barrier properties of ordinary blister packaging, people have developed cold forming rigid sheets to replace the the vacuum blister forming, so that the cold forming blister foil can be used as as the blister forming material.

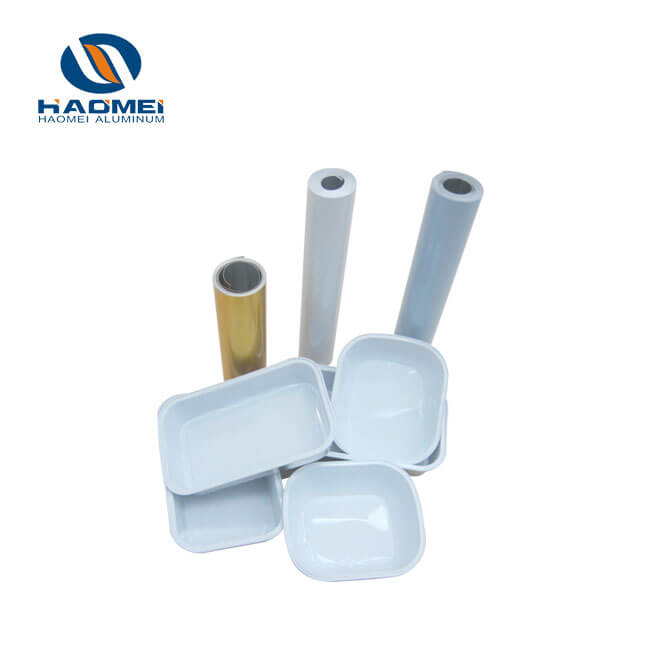

The use of high-strength aluminum foil in cold-stamping makes the cold-stamping hard sheets have extremely high water vapor, oxygen and light barrier properties that cannot be achieved by any other material.

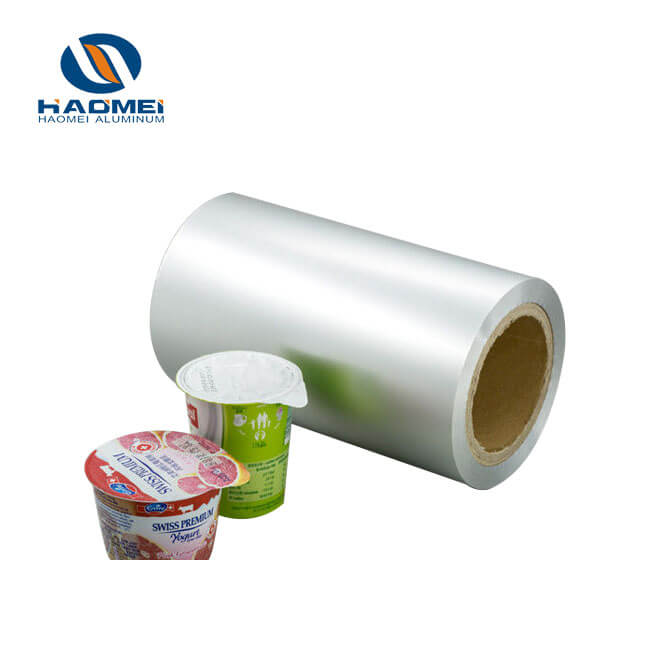

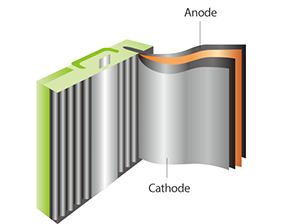

The cold-stamping hard sheet is generally composed of three functional layers: the surface supporting strength layer, the middle aluminum foil barrier layer, and the inner surface heat sealing layer. The surface layer can be printed with the color or pattern required by the customer, and the layers are bonded together to form a composite film as a whole(as shown in the picture).

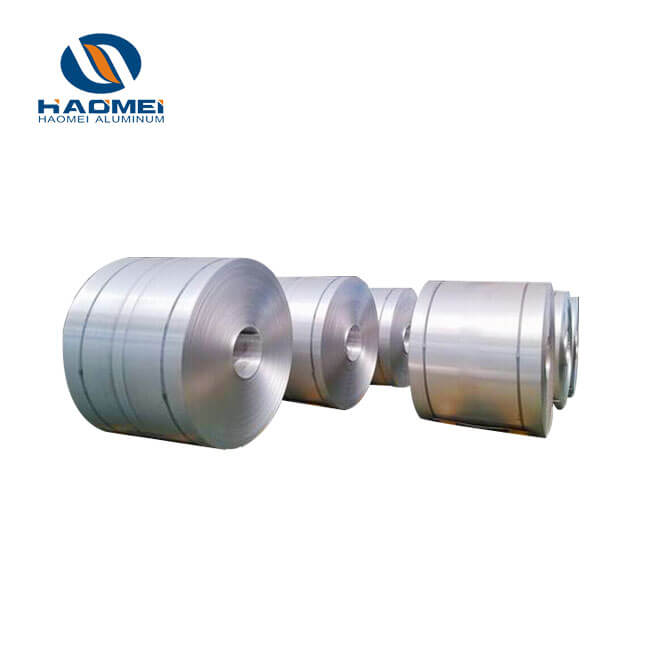

The blister foil used in cold stamping not only performs the barrier function, but also has the functions of strength support, and stamping and stretching resistance, so it is different from the general flexible packaging composite aluminum foil. It needs to be of extremely high strength and good extensibility.

Since the cold forming needs to be stamped, the thickness of the aluminum foil used is much thicker than that of the ordinary composite film. Generally, 45μm thick aluminum foil is used. For the shallow stamping, the aluminum foil thickness is reduced to 30μm. For applications where the punched bubble is particularly deep (≥15mm), the maximum thickness can be increased to 70μm.

The pharmaceutical aluminum foil for cold forming is 8021-O and 8279-O aluminum foil with a thickness of 0.025-0.08mm. The 8021 and 8079 aluminum foil produced by Haomei Aluminum , have high cupping value, high heat seal strength, no pinholes and good air tightness. Haomei Aluminum has been a long-term cold forming blister foil supplier for various medical packaging companies at home and abroad.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China