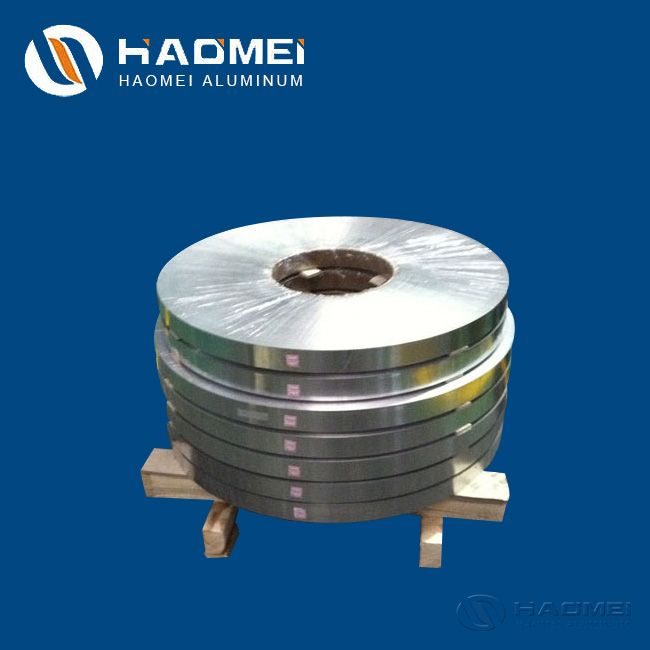

Aluminum Flat Strip for Transformer in Mexico

Aluminum strip for transformer winding are the main choice for different transformers such as dry and low voltage in North America. What are the quality requirements? Learn more.

A transformer is a static motor used to transfer alternating current at a steady frequency from one circuit to another through the process of electromagnetic induction, but with voltage increased or decreased as required.

It is understood that each transformer includes different components such as iron core, winding, coil, insulating material, oil conservator, oil, vent hole, tap changer, Buchtz relay, cooling pipe and explosion-proof door, among which the transformer winding plays a critical role in operation.

Transformer winding materials are aluminum flat strip and copper, which are the most commonly used conductors in transformer windings. Copper has high mechanical strength and electrical conductivity, while aluminum is lighter and cheaper than copper. Typically, copper windings are used for large transformers, while aluminum conductors are used for small and medium-sized transformers.

Aluminum strip for transformer winding are the main choice for different transformers such as dry and low voltage in North America. Copper windings are the main winding material in most parts of the world, but the main reason for choosing this aluminum winding is its low initial cost.

Aluminum's maximum resistivity provides fewer eddy current losses within the winding, which reduces the likelihood of hot spots. Transformers with aluminum or copper windings have the same losses and performance. But aluminum wound coils are larger compared to copper coils. Haomei Aluminum provides aluminum strip for transformer winding.

Alloy | Thickness(mm) | Width(mm) | I.D of Coil(mm) | O.D. of Coil(mm) |

1050/1060/ 1070/1350 | 0.1-3.0 | 30-1600 | 76/152/305 /405/505 | Max. 1000 |

Mechanical properties

Alloy&temper | Thickness (mm) | Mechanical Property | |

Tensile Strength Rm/(N/mm2) | Elongation A50mm/% | ||

1050 O 1060 O 1070 O

| 0.1-0.2 | 60-95 | ≥20 |

0.2-3.0 | ≥25 | ||

Thickness Tolerance

Thickness | Thickness Tolerance |

0.1-0.2 | +/-8%

|

0.2-0.4 | +/-0.02 |

0.4-0.8 | +/-0.03 |

0.8-1.1 | +/-0.04 |

1.1-1.4 | +/-0.05 |

1.4-2.0 | +/-0.06 |

2.0-2.5 | +/-0.07 |

2.5-3.0 | +/-0.08 |

Width tolerance

Thickness(mm) | Width tolerance(%) | ||||

<100 | 100-300 | 300-500 | 500-1250 | 1250-1500 | |

>0.1-0.20 | +/-0.15 | +/-0.2 | +/-0.3 | +/-0.5 | +/-0.5 +/-1 |

0.20-0.60 | +/-0.15 | +/-0.2 | +/-0.3 | +/-0.75 | +/-0.5 +/-1.25 |

0.60-1.0 | +/-0.15 | +/-0.25 | +/-0.5 | +/-0.75 | +/-0.5 +/-1.25 |

1.0-2.0 | +/-0.2 | +/-0.35 | +/-0.6 | +/-1 | +/-0.5 +/-1.25 |

2.0-3.0 | +/-0.5 | +/-0.5 | +/-0.75 | +/-1 | +/-0.5 +/-1.25 |

Physical and mechanical properties of thin aluminum strips

Density in 20 ℃ | Max. Resistivity in 20 ℃

| Electric Conductivity | Hardness |

2.703 kg/dm3 | ≤ 0.02825 Ω mm2/m

| ≥61.4%

| Appro.20 HB |

Burrs and collapse

The width of aluminiums trip (mm) | Burr’s height (mm) | Collapsed side’s height (mm) |

<0.2 | 0.01 | ≥0.05-0.1 |

0.2-1.0 | 0.015 | |

1.1-1.5 | 0.02 | |

>1.6 | 0.03 |

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China