3003-h14 Aluminum Plate for Lithium Battery Shell

In order to reduce the weight of the battery, it is an inevitable choice to use 3003 h14 aluminum plate to make lithium battery shell. What are its properties? Learn more.

Due to he increasing need for lightweight vehicles in recent years, high energy density and lightweight have become the development direction of future vehicle power batteries. At present, there are many technical routes for domestic new energy vehicles in terms of vehicle batteries.

Under the current technical standards, cylindrical batteries, square batteries, and soft-pack batteries have become relatively mature power carriers in the field of pure electric passenger vehicles.

In order to increase the cruising range, new energy electric vehicles need a large number of lithium battery combination modules. Each module is composed of several battery boxes, so the quality of each battery box has a great influence on the quality of the entire battery module. In order to reduce the weight of the battery, it is an inevitable choice to use 3003 h14 aluminum plate to make lithium battery shell.

3003 aluminium sheet belongs to an aluminum-manganese alloy, and the main alloying element is manganese. The boiling point temperature of aluminum and manganese is not much different, so there will be no problems such as the deterioration of weld seam quality due to the burning of metal elements during welding.

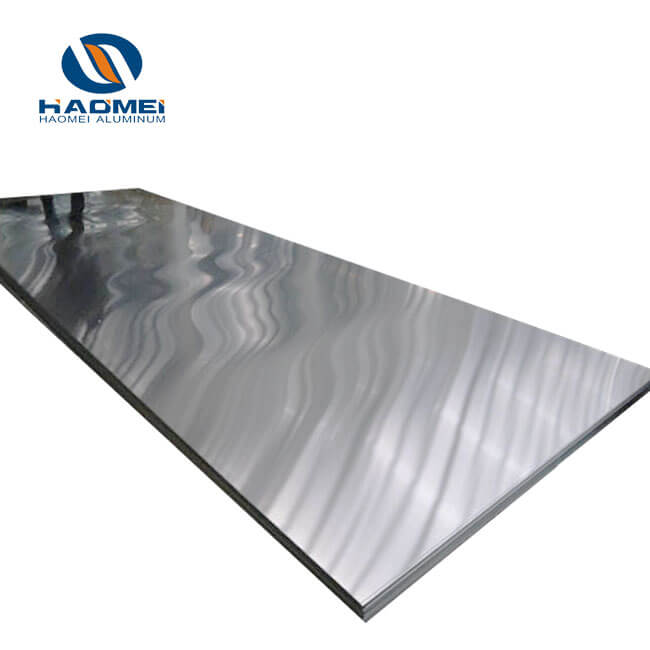

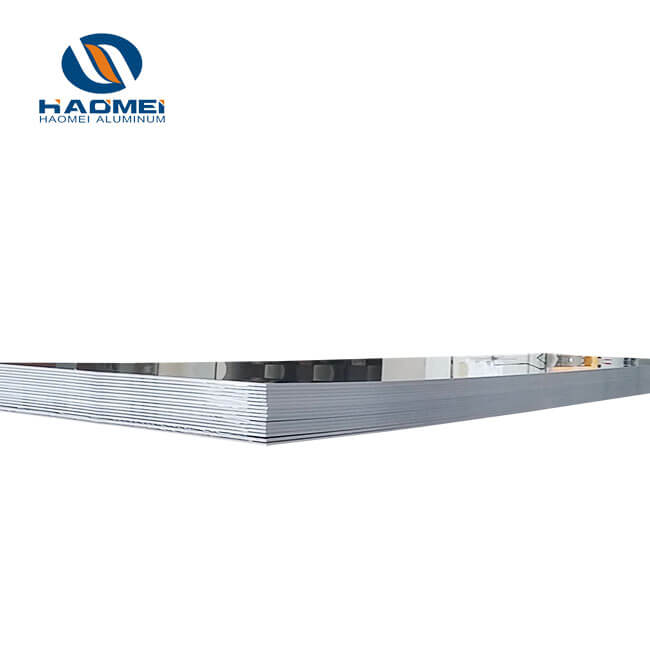

3003 aluminum alloy has low density and soft material, and has the advantages of being easy to stretch and form the aluminum shell of the power battery as a whole. It has been used by many companies for battery packaging. The density of aluminum alloy is much smaller than that of traditional stainless steel packaging materials.

3003 H14 aluminum sheet is used for square lithium battery case. In electric vehicle manufacturing, 3003H14 power battery case is the main material of power batteries. The 3003 aluminum sheet for power battery shells is undergoing a transition from "0 state" to "H14" state. The fundamental reason lies in the advancement of technology.

"O state" material has the characteristics of low production efficiency and high yield. The material in the "H14" state is more suitable for automatic and semi-automatic punching, and has higher production efficiency. Therefore, some large-scale and powerful power battery manufacturers are currently using 3003 H14 aluminum plate.

What are the 3003-h14 aluminum mechanical properties? It refers to the finished product after the aluminum plate undergoes secondary processing after the annealing process, and then comes out after cold rolling, and is not subjected to heat treatment. The strength of the aluminum plate processed in this way will be relatively high, but the tensile strength is relatively small. The tensile strength of 3003-H14 is greater than 140MPa, while that of H24 is 240MPa.

The lithium battery shells have more strict requirements on the chemical composition of 3003 aluminum sheet. Haomei Aluminum has a good control in order to produce raw materials suitable for battery shell materials.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China