What Is The Manufacturing Process of Traffic Aluminum Disc Circle

1060 alloy, 1070 alloy, and 3003 alloy are the three most commonly used alloys in the production and customization of aluminum discs. 3003 alloy is more often used to make traffic aluminum disc circles.

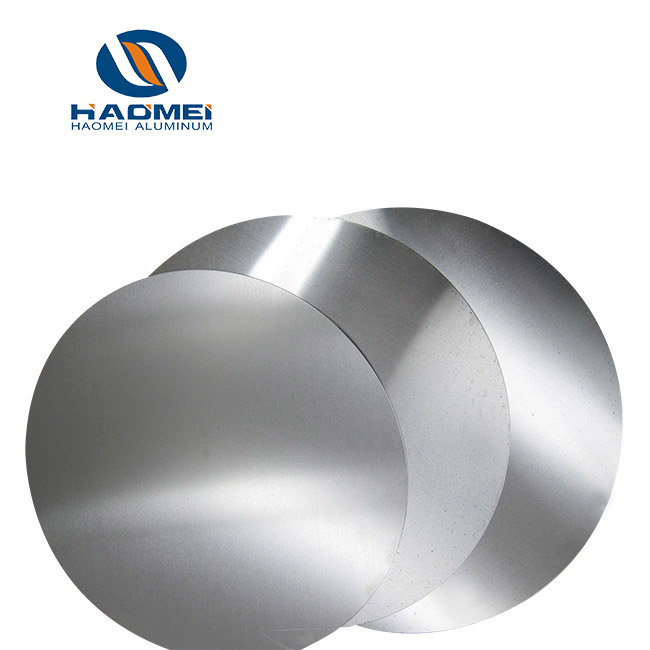

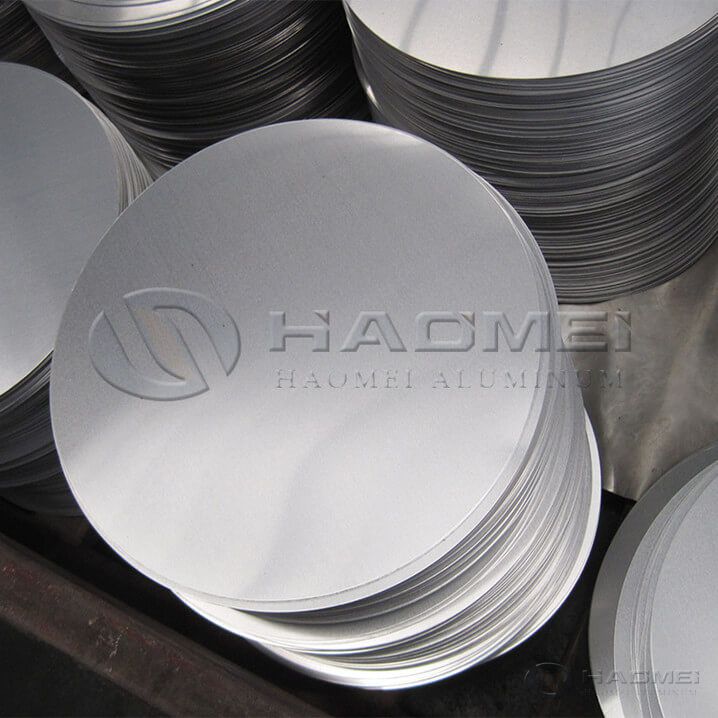

Traffic signs are mostly made of aluminum alloy plates. Due to their light weight and corrosion resistance, they can be used in various severe weather and environments. At present, the traffic aluminum disc circle used in the market are pure aluminum alloy or rust-proof aluminum alloy. The aluminum discs circle diameters are 60, 80, and 100 cm.

1060 alloy, 1070 alloy, and 3003 alloy are the three most commonly used alloys in the production and customization of aluminum discs. Due to the addition of the manganese element, the strength of 3003 aluminum discs is higher than that of conventional 1060 aluminum discs. How are they produced?

Aluminum alloy selection

We need to choose the right aluminum alloy. The selection of aluminum alloys should take into account the purity and chemical composition of the material. High-purity aluminum has better processing performance and corrosion resistance.

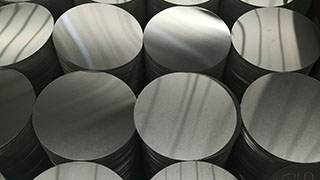

Aluminum circle cutting

Cutting can use traditional mechanical cutting methods such as sawing and shearing. Of course, in modern industry, high-tech means such as laser can also be used for cutting.

Heat treatment

In order to improve the hardness and strength of aluminum sheet, heat treatment can also be carried out. Heat treatment refers to the process of heating and cooling to change the grain structure of aluminum sheet, so as to achieve the predetermined hardening effect. Specific heat treatment methods include aging treatment, solution treatment, etc.

Surface treatment

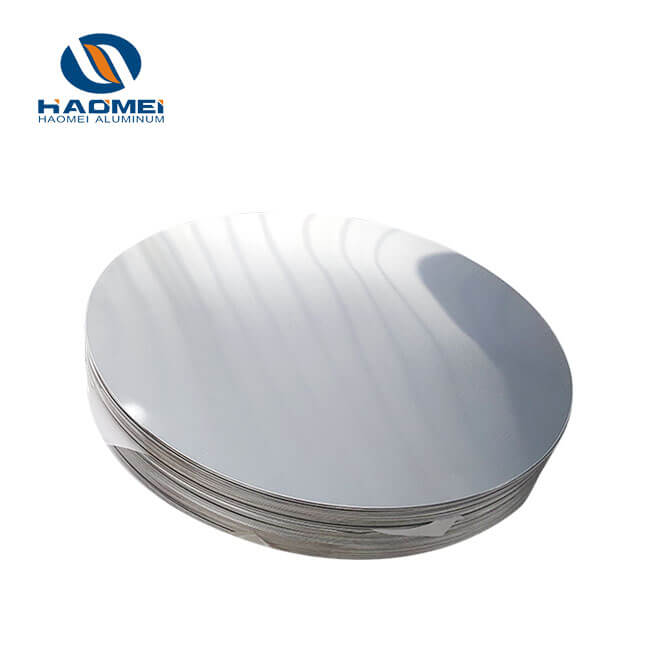

In order to improve the surface quality of aluminum discs, surface treatment can be performed. This includes mechanical polishing, chemical treatment or electrochemical treatment, etc. Mechanical polishing can eliminate burrs, depressions and unevenness on the surface. Chemical or electrochemical treatment can increase the corrosion resistance of aluminum sheets and improve the durability of round aluminum sheets.

Inspection

Surface treatment can further improve the appearance and texture of the aluminum discs, such as spraying, anodizing, etc. Quality inspection can include inspections of appearance quality, dimensional accuracy, hardness and other indicators to ensure that the quality of the aluminum circle disc meets the standards.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China