What Are The Requirements of Cigarette Inner Packaging Foil

The cigarette inner packaging foil plays the role of preserving the fragrance, moisture and light-shielding for tobaccos. What are its specific requirements like thickness, width and length tolerance? Learn more.

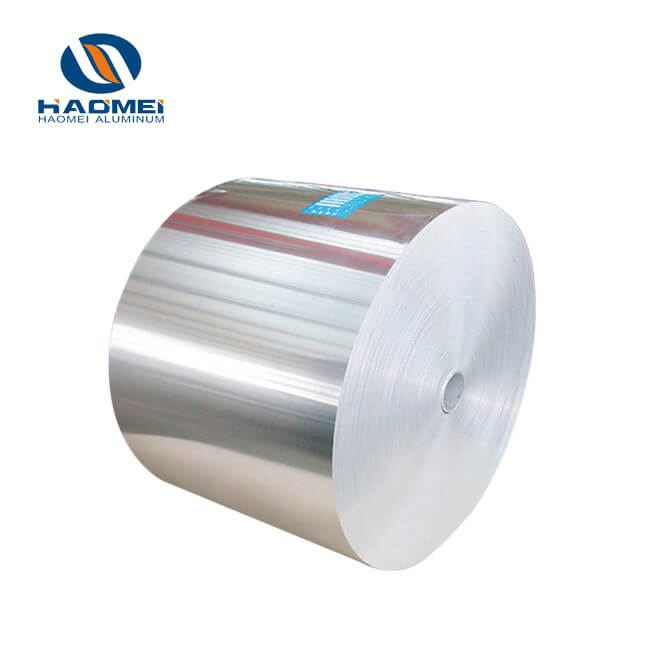

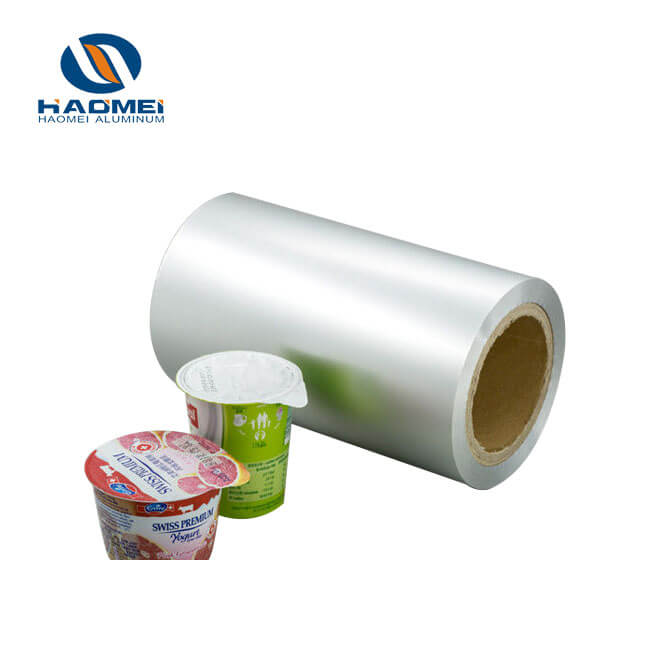

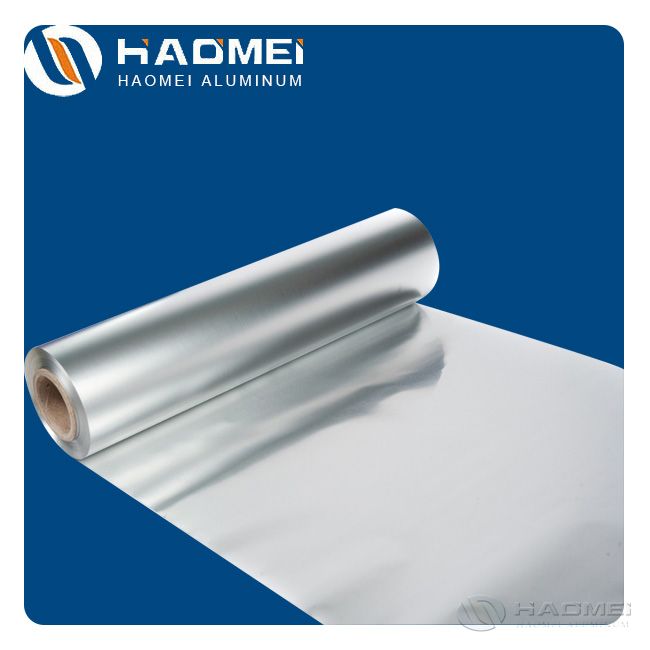

The cigarette inner packaging foil is the paper between the cigarette and the cigarette pack. As the initial packaging layer of cigarettes, it plays the role of preserving the fragrance, moisture and light-shielding for cigarettes. Commonly used cigarette lining papers are mainly composite aluminum foil lining papers.

Alloys of cigarette aluminum foil

Alloys | Temper | Thickness(mm) | Width(mm) | ID(mm) | OD(mm) |

1235/8079 | O | 0.006-0.009 | ﹤1500 | 76,150,152 | 300-450 450-820 |

Thickness tolerance

Thickness | Thickness tolerance |

0.006-0.0065 | ±5%.T |

﹥0.0065-0.009 | ±4%.T |

Width tolerance

Width(mm) | Symmetrical deviation | Unidirectional positive deviation | Unidirectional negative deviation |

≦1200 | ±1 | 0+2 | 0-2 |

﹥1200 | ±2 | 0+4 | 0-4 |

Length tolerance(meter)

No less than 90% of the rolls in each batch | No more than 10% of the rolls in each batch |

±1%×nominal length | ±2%×nominal length |

Staggered layers and tower shapes

The end faces of aluminum foil are not allowed to have staggered layers or tower shapes that affect the use.

Glossiness

The glossiness of the same batch of aluminum foil should be uniform and consistent. When the buyer has requirements for the glossiness of aluminum foil, visual measurement or the instrument method can be used to detect the glossiness according to the contract.

Room temperature tensile mechanical properties

Alloys | Temper | Thickness(mm) | Tensile strength Rm MPa | Elongation after break, not less than %(A50mm) | Elongation after break, not less than %(A100mm) |

1235 | O | 0.006-0.009 | 55-100 | 1.0 | |

8079 | 65-110 | 1.2 | |||

Pinholes

Thickness(mm) | Number of pinholes, no more than pcs/m2 |

0.006 | 1000 |

﹥.0060~0.0065 | 600 |

﹥0.0065~0.0075 | 300 |

﹥0.0075~0.0090 | 150 |

Adhesion

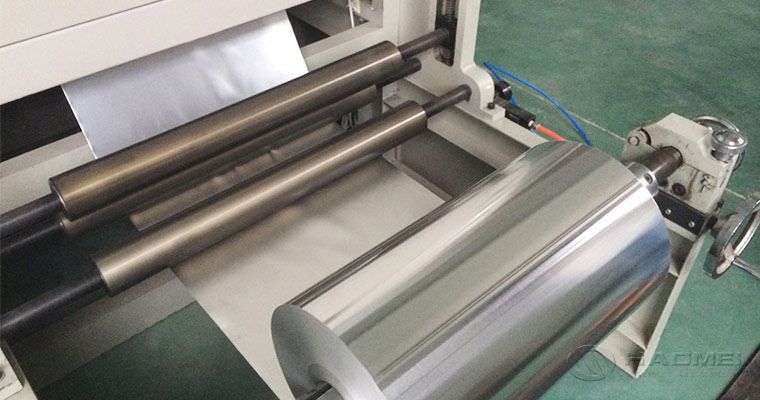

The unwinding performance of the aluminum foil should be good, and no adhesion or tearing is allowed when unfolding. The adhesion test result of the aluminum foil should not exceed 0.5m.

Wettability

The surface of the aluminum foil in state O should be free of oil spots, and the surface wettability should reach Class A.

Appearance quality

1. The aluminum foil has a glossy side and a dark side, with the glossy side facing outward and the dark side facing inward. If you have the opposite requirements, welcome to tell us in advance.

2. The surface of the aluminum foil should be clean and flat, and no defects such as mosquitoes, corrosion, roller marks, abrasions, scratches, oil spots, bumps, wrinkles and obvious color differences that affect the use are allowed.

3. The end surface of the aluminum foil roll should be neat, with smooth edges and no burrs.

4. The aluminum foil roll should be tightly wound, and no sliding between layers or core detachment is allowed.

5. Haomei Aluminum is one of the big cigarette foil paper manufacturers. Welcome to contact us to inquire the aluminum foil price directly.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China