The Manufacturing Process of Aluminum Strip For Cosmetic Cap

What’s the manufacturing process of aluminum strip for cosmetic caps? Haomei, aluminum bottle cap material supplier, tells you. Learn more!

At present, most of the cosmetic bottle caps on the market are made of plastic and aluminum-plastic composite materials. In comparison, aluminum-plastic caps have better sealing performance and attractive appearance. Therefore, it is the primary choice of the high-end cosmetics.

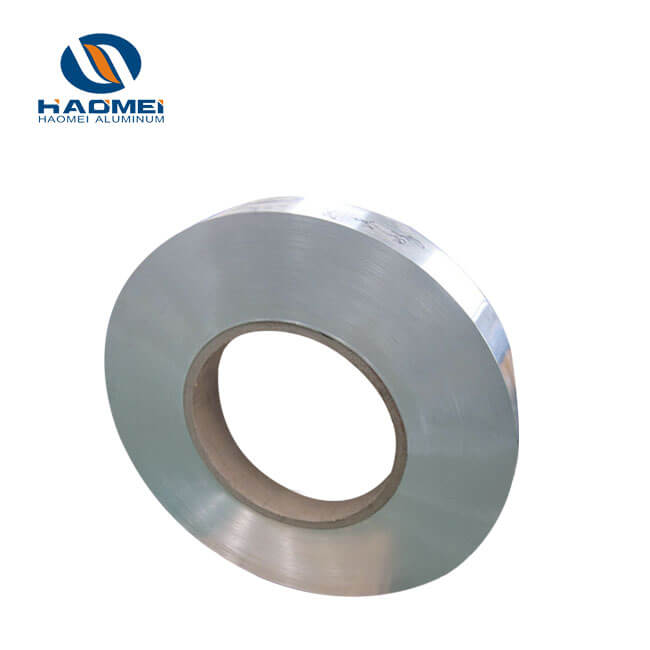

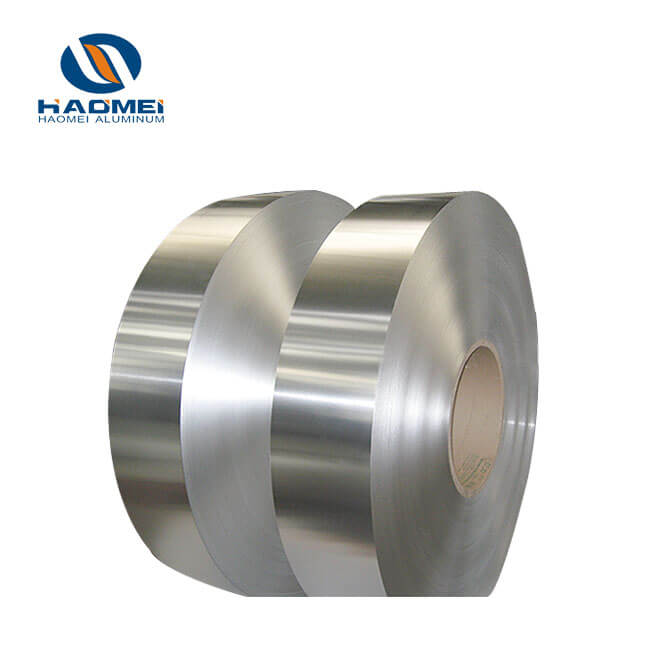

The aluminum strip for cosmetic cap features bright surface, stable mechanical properties, accurate dimensional tolerances, easy stamping and forming, small ear making rate after stamping into bottle caps, and good anodizing effect.

What is the manufacturing process of aluminum strip for cosmetics? This is one of our manufacturing methods.

1. Prepare the aluminum ingot. Each element weight percentages: Si≦0.08%, Fe≦0.1%, Cu≦0.03%, Mn≦0.02%, Mg≦0.02%, 0.01%≦Ti≦0.02%. The rest is Al.

2. Surface milling: The milling width of the face is 5-30 mm and that of side face is 4-25 mm.

3. Even heating: the furnace gas is set at a temperature of 550℃ and the temperature is kept for 12 to 30 hours, and the temperature when the ingot leaves from the furnace is 480 to 500℃.

4. Hot rolling: The ingot with a thickness of 420-620 mm after milling the surface is rolled by a hot rolling machine for 15 to 23 passes, which is rolled into an aluminum coil with a thickness of 2.5-6.0 mm, and the final rolling temperature is 250 -285℃.

5. Cold rough rolling: After hot rolling, the aluminum coil with a thickness of 2.5 to 6.0 mm is cold rolled into the aluminum coil with a thickness of 0.33 to 2.0 mm after 1 to 2 passes, and the rolling speed is 120 -900 m/min.

6. Cleaning. It is cleaned with high-pressure and high-temperature water on the washing machine.

7. Intermediate annealing. In the vacuum annealing furnace, the furnace gas temperature is 370 to 500 ℃ , and the holding time is 9 to 18h for complete recrystallization annealing

8. Cold finish rolling. The thickness will be rolled into 0.2 to 1.2mm in one pass.

9. Stretching, bending, straightening, cleaning and trimming

10. Inspection.

As a big aluminum bottle cap material supplier, Haomei Aluminum has rich kinds of aluminum alloy products such as aluminium strip, aluminum sheet, aluminum foil for cap closure of medicine, cosmetics, beverage and wine.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China