The Key Casting Process Affecting Double Zero Aluminum Foil Blank

What are the factors affecting the quality of double zero aluminum foil? We need to have a strict control of the casting process of light gauge foil. Learn more.

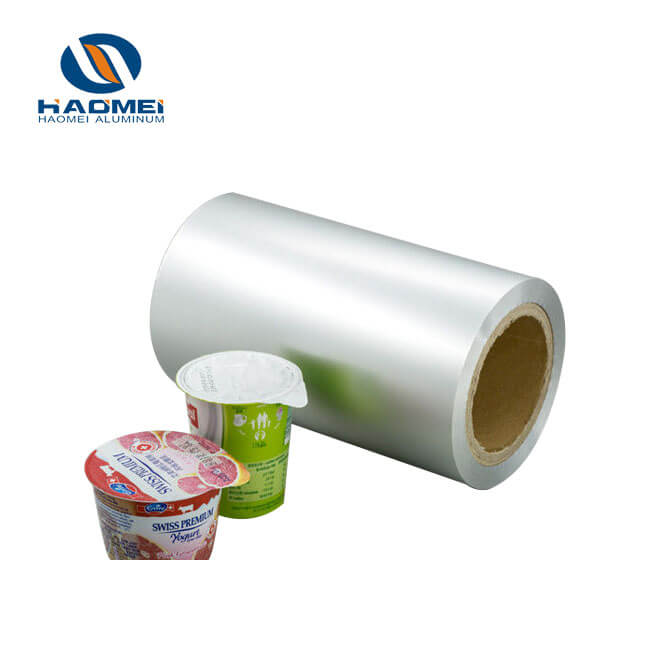

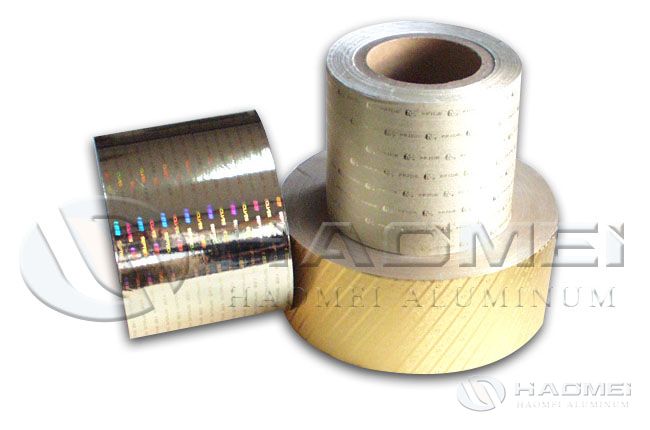

The majority of aluminum foil is made from 99.0% to 99.5% of industrial pure aluminum, among which the common alloys are 1100, 1145, 1235, 1350 and 8079. It has been proved that 1235 and 8079 aluminum alloy are most suitable for the production of light gauge foil, especially double zero aluminum foil. What are the factors influencing the quality of the light gauge foil blank?

Alloy composition

At present, more than 90% of domestic double zero aluminum foil production uses 1235 alloy, while 8079 alloy is generally used in Europe and America. The main impurity elements in 1235 industrial pure aluminum are Fe and Si. Fe and Si are mainly added to the smelting furnace in the form of alloy element additives during the batching.

The content of Si/ Fe, Fe/Si ratio and the size of the compound phase have a significant impact on the rolling performance of aluminum foil.

Smelting and holding temperature and time

The melting point of aluminum is about 660°C, and the general melting temperature is lower than 755°C. The temperature of the molten aluminum should be controlled according to the ambient temperature and the length of the trough outside the furnace. If the molten aluminum stays in the static furnace for too long or the temperature of the molten aluminum is too high, the cast-rolled slab grains will be coarse.

Degassing, Deslaggging and online filtration

Melt purification is to use physical and chemical principles and corresponding technological measures to remove gases, impurities and harmful elements in liquid metal in order to obtain pure aluminum melt. The gas in the melt is mainly hydrogen (H2). Inclusions include oxides suspended on the surface of the melt, oxides in the melt due to processes such as refining, stirring, and refractory materials suspended in the melt.

Grain refinement

The size and uniformity of the cast-rolled billet grains directly affect the pinhole rate and yield of aluminum foil. The small equiaxed grain structure has small anisotropy, uniform processing deformation, and good mechanical properties and processing properties of the blank, which is beneficial to the rolling and forming of the blank.

As an experienced aluminum foil producer, Haomei Aluminum has strict control of each process. Welcome to leave message below to get the latest price of double zero aluminum foil.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China