Hydrophilic Aluminum Foil VS Hydrophobic Foil

Inside every operating air conditioner, there are two types of aluminum foil with drastically different "personalities"—hydrophilic aluminum foil and hydrophobic aluminum foil. The former is the "efficiency driver" of the evaporator an

Inside every operating air conditioner, there are two types of aluminum foil with drastically different "personalities"—hydrophilic aluminum foil and hydrophobic aluminum foil. The former is the "efficiency driver" of the evaporator and condenser, facilitating rapid heat exchange and cooling; the latter plays a "protective role" in certain special structures, resisting the intrusion of oil and moisture.

Coating

Whether hydrophilic or hydrophobic, the special properties of aluminum foil stem from its surface functional coating, which is also the core difference between the two.

The coating of hydrophilic aluminum foil is usually based on inorganic silicates and organic resins, with the addition of hydrophilic active ingredients. The molecular structure of this coating contains a large number of polar groups, such as hydroxyl groups (-OH). These groups act like "little hands," actively binding with water molecules, allowing water to spread smoothly on the aluminum foil surface.

To improve the coating's durability and thermal stability, some high-end hydrophilic aluminum foils also incorporate nano-sized silica and other components to enhance the adhesion between the coating and the aluminum foil substrate, preventing peeling off under long-term high-temperature environments.

Conversely, the coating of hydrophobic aluminum foil follows a "repulsion" route. The coatings of hydrophobic aluminum foils often use fluorinated resins (such as polytetrafluoroethylene) and silicone resins.

These materials contain numerous non-polar groups in their molecular structure, resulting in extremely low surface tension. When water molecules land on the surface, they cannot effectively bind with the coating molecules, forming only spherical water droplets, thus achieving a "water-repellent" effect.

Some hydrophobic aluminum foils undergo special nanotexturing treatments, creating tiny uneven structures on the coating surface to further enhance hydrophobic properties, even reaching "superhydrophobic" levels—water droplets rolling on the surface can even carry away dust, achieving a self-cleaning function.

Colors

Besides performance, color is also a direct indicator distinguishing between two types of aluminum foil, which is also closely related to the coating composition.

Hydrophilic aluminum foils are primarily light-colored, most commonly silver-white and light gray, with some also made in light blue or light green depending on the application.

This is because their coatings are mostly transparent or light-colored, and to ensure heat exchange efficiency, dark pigments are usually not added—dark colors easily absorb heat and interfere with the heat exchange process of refrigeration equipment such as air conditioners and refrigerators.

This light-colored appearance also makes hydrophilic aluminum foil look clean and simple inside the equipment, meeting the visual requirements of internal appliance components.

Hydrophobic foil offers more flexibility in color selection, ranging from light colors like silver-white to dark colors like black and dark gray. On one hand, the coating material itself can be formulated in a variety of colors; on the other hand, hydrophobic aluminum foil has a wider range of applications.

In some applications (such as oven liner and range hood panels), decorative color is important, and darker colors can also provide a dirt-resistant visual effect, concealing minor oil stains or dirt. However, hydrophobic aluminum foil used in heat dissipation equipment is still primarily light-colored to avoid affecting heat dissipation efficiency.

Performance

In terms of water contact, the two are polar opposites. Hydrophilic aluminum foil typically has a water contact angle of less than 30°, allowing water molecules to quickly spread into a uniform water film on its surface without forming water droplets. Hydrophobic aluminum foil, on the other hand, generally has a water contact angle greater than 90°, with superhydrophobic aluminum foil even reaching over 150°, causing water droplets to easily roll off the surface.

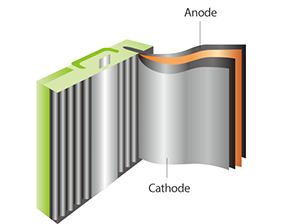

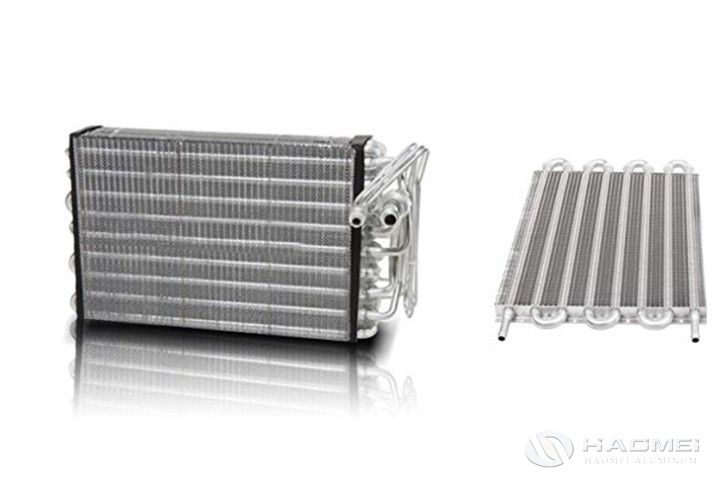

In terms of heat exchange efficiency, hydrophilic aluminum foil has a clear advantage. In devices such as air conditioner evaporators and refrigerator condensers, the water film on the surface of hydrophilic aluminum foil increases the contact area with air, allowing condensate to evaporate or drip off quickly, reducing the obstruction of airflow by water droplets and thus improving heat exchange efficiency.

On the other hand, water droplets on the surface of hydrophobic aluminum foil form a certain insulating layer, which may slightly reduce heat exchange efficiency in refrigeration equipment, thus limiting its application in these scenarios.

Regarding corrosion resistance, both are superior to ordinary aluminum foil, but with different focuses. The coating of hydrophilic aluminum foil isolates water and air, preventing corrosion of the aluminum foil substrate by condensate, extending its service life, especially in humid environments.

The fluorinated or silicone coating of hydrophobic aluminum foil has stronger chemical stability, not only preventing corrosion but also resisting the erosion of oil, acids, and alkalis, and offering better weather resistance, performing better in harsh environments.

In terms of cleaning difficulty, hydrophobic aluminum foil has the upper hand. The hydrophobic coating on its surface is resistant to water stains and oil. Even if stains are present, they can be washed away by water droplets, and daily cleaning only requires wiping with a damp cloth. In contrast, the water film on the surface of hydrophilic aluminum foil easily attracts dust from the air, and over time, scale or stains may form on the surface. When cleaning, a mild detergent should be used to avoid damaging the coating.

Applications

The core application area for hydrophilic aluminum foil is the refrigeration and air conditioning industry. Whether it's the evaporator of a household air conditioner, the condenser of a cabinet air conditioner, or the heat dissipation components of refrigerators and freezers, hydrophilic aluminum foil is indispensable.

In these devices, hydrophilic aluminum foil effectively improves heat exchange efficiency, reduces condensation residue, lowers energy consumption, and prevents corrosion of the aluminum foil by condensation, extending the lifespan of the equipment. Furthermore, hydrophilic aluminum foil also functions well in scenarios such as the evaporator plates of humidifiers and the heat exchange plates of water heaters due to its excellent hydrophilicity.

The application scenarios for hydrophobic aluminum foil are more diverse, and it is particularly adept at handling complex environments of "humidity + oiliness". In kitchen appliances, hydrophobic aluminum foil is commonly used in the panels and filters of range hoods, and the interiors of ovens and microwave ovens. Its oil-repellent, water-repellent, and easy-to-clean properties effectively reduce grease buildup, making kitchen cleaning easier.

In outdoor applications, hydrophobic aluminum foil can be used as a waterproof coating for awnings and in the housings of outdoor lighting fixtures, resisting wind and rain erosion thanks to its weather resistance and water resistance. In industrial applications, hydrophobic aluminum foil is also used in corrosion-resistant components of chemical equipment and in the heat insulation layers of automotive exhaust pipes, leveraging its strong chemical stability.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China