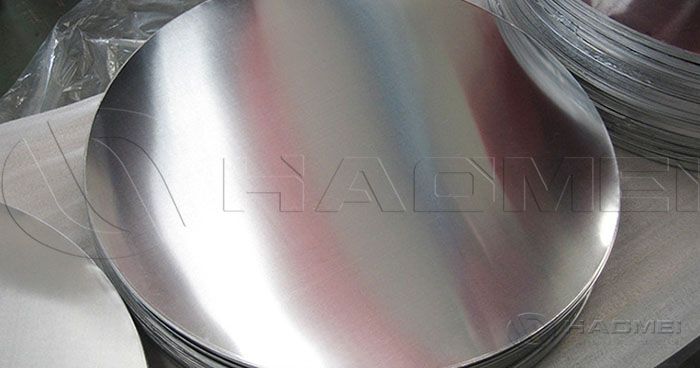

How to Test Quality of The Circle Aluminum?

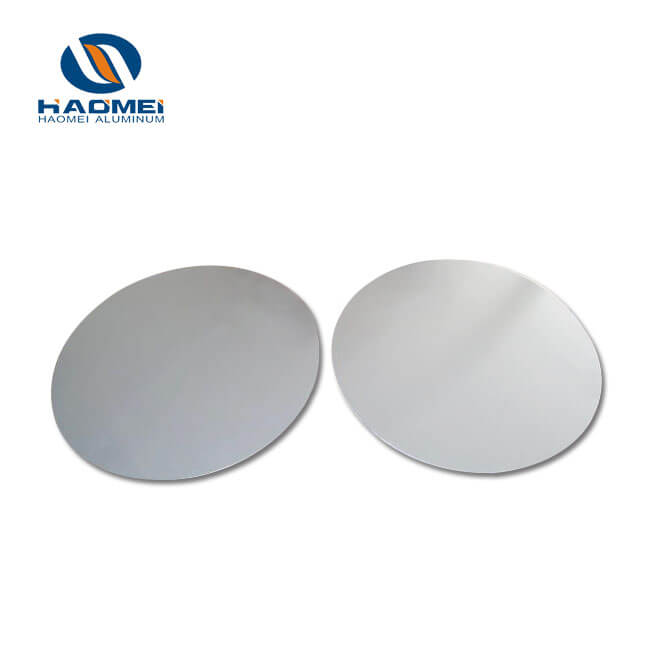

The circle aluminum is widely used in kitchenware, pots, equipment, and traffic signs. How to ensure its quality? There are visual inspection,size inspection,chemical analysis, mechanical properties testing,etc.

Usually, the circle aluminum is mainly used in kitchenware, pots, equipment, and traffic signs. 1060, 1070 and 3003 alloys are the three most commonly used alloys in the production of the aluminum discs circle. 060 and 1070 aluminum alloys are used in large quantities in pots; 3003 is used most in the field of traffic signs.

Aluminum discs need to undergo a series of quality inspections before use to ensure that they meet the requirements and have good performance and reliability. The following is the general aluminum circle inspection process.

Firstly, perform a visual inspection. Check the surface of the round aluminum sheet cratches, bubbles, dents and other defects, and check for obvious deformation or cracks. These defects may affect the performance and service life of aluminum circles.

Secondly, carry out size inspection. Use measuring tools or measuring instruments to measure the diameter, thickness and other dimensions of the aluminum disc to ensure that it meets the design requirements.

The next is to do a chemical composition analysis. By using chemical analysis instruments, the content of various elements in the aluminum discs is detected to ensure that they meet relevant standards. Chemical composition analysis is critical to the performance of aluminum discs as well as subsequent processing and use.

Then, perform mechanical property testing. Through tensile testing, hardness testing and other methods, the strength, hardness, ductility and other mechanical properties of the aluminum discs are tested. These tests can determine whether the strength of the aluminum disc meets the requirements and predict its performance under actual use conditions.

In addition, corrosion resistance testing is required. Aluminum circles are usually used in various environments, especially in humid and corrosive environments, so the corrosion resistance of aluminum discs needs to be tested. Commonly used test methods include salt spray test and damp heat test.

Finally, there are some non-destructive testings. They include ultrasonic testing, radiographic testing and other technologies, which are used to detect internal defects in aluminum discs like pores, inclusions, etc. Non-destructive testing can assess the quality and usability of samples without destroying them.

These testing items can comprehensively evaluate the quality and performance of aluminum discs to ensure that they meet usage requirements. Haomei Aluminum is one of the big aluminum circle and anodized aluminum discs manufacturers. Welcome to leave message below to inquire what you need.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China