DC Light Gauge Foil Jumbo Roll for Hairdressing

The common used alloys are 1235 and 1200 DC aluminium jumbo roll for making hair foil. What are the differences of DC and CC aluminum foil? Learn more.

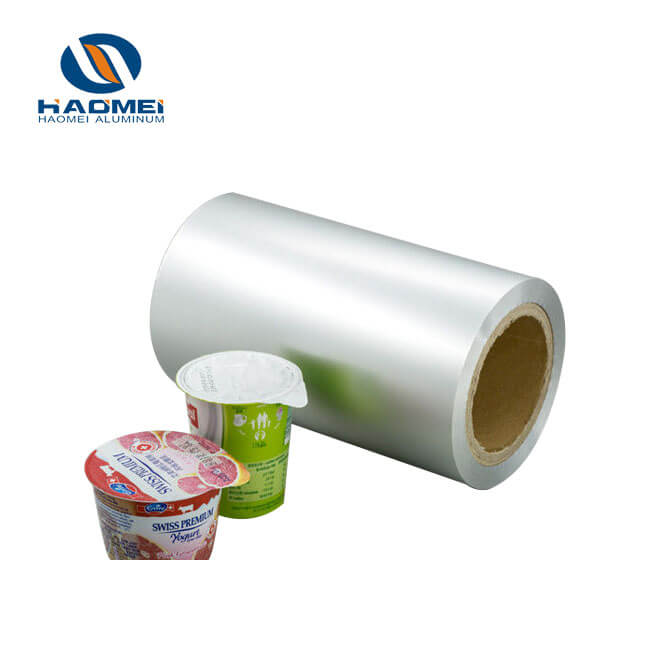

The aluminum jumbo roll from heavy gauge aluminum foil to light gauge foil is of wide applications. In food packaging, it has rich varieties, including household foil, container foil, flexible packaging foil, Tetra Pak/Combi packaging foil, beer sealing foil, etc.

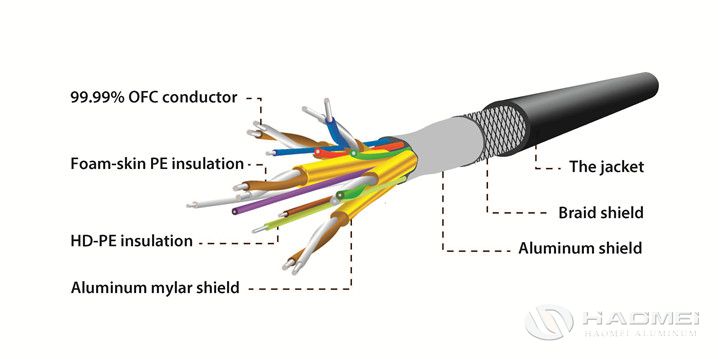

In addition to food aluminum foil, it is also used as medicinal foil, cigarette foil, hairdressing foil, and decorative foil for interior walls of buildings and interior furniture. Other application fields include battery foil, battery soft foil, electronic label foil, circuit board foil, aluminum foil for air-conditioning ducts,etc.

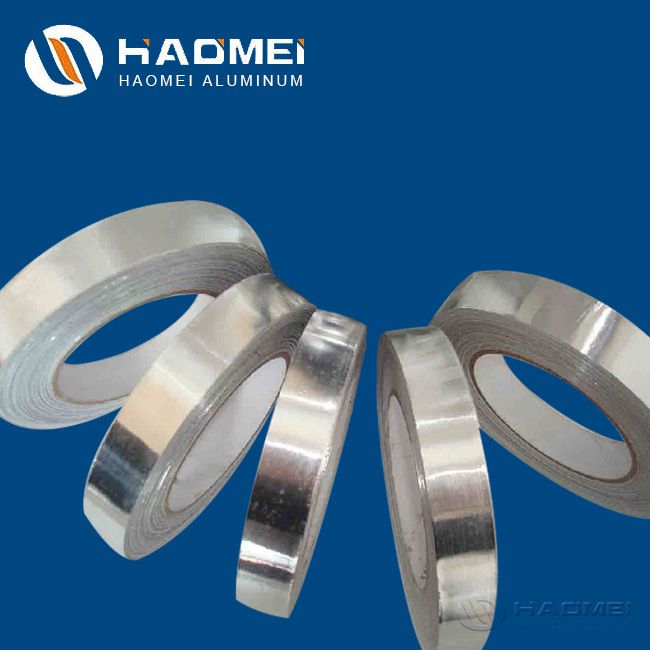

Light gauge foil can be further cut or painted as the hair foil. It is widely used in hairdressing in Europe and America. It has a heat preservation effect, which can shorten the time of hair treatment and avoid the pollution of hairdressing chemicals.

The common used alloys are 1235 and 1200 DC aluminum foil. In terms of the processing technology, do you know the differences between DC and CC Aluminum foil?

Compared with hot-rolled billets, the quality of cast-rolled billets is more difficult to control. Since the deformation of aluminum foil rolled with cast-rolled billets (thickness of 6-8mm) is much smaller, the quality of cast-rolled billets, such as air passages, inclusions, segregation, coarse grains, and other defects, has a greater impact on aluminum foil rolling quality.

If the electrolytic aluminum liquid is used to directly for the production of aluminum foil blanks, the production process eliminates the casting and remelting procedures of aluminum ingots, greatly reducing the energy consumption of remelting and casting, and reducing the secondary remelting. It has been widely used by smelting and processing enterprises.

However, due to the characteristics of electrolytic aluminum liquid, its injection into the mixing furnace makes it difficult to formulate and control the subsequent casting-rolling, cold-rolling, foil-rolling, annealing and other production processes. Therefore, in the entire production process, the strict control of the process are very important.

The aluminum foil blanks produced by the casting-rolling method and the hot-rolling method have different mechanical properties during the aluminum foil rolling process. The CC material has high strength, the rolling work hardening speed is fast, and the final annealing performance of the aluminum foil is also different.

After annealing at the same temperature and time, the aluminum foil produced by CC material has high strength, while the aluminum foil produced by DC material has low strength. Therefore, to produce aluminum foil with different blanks, different rolling, slitting, and annealing processes should be used. Welcome to leave message below to inquire 1200 aluminum foil for hairdressing.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China