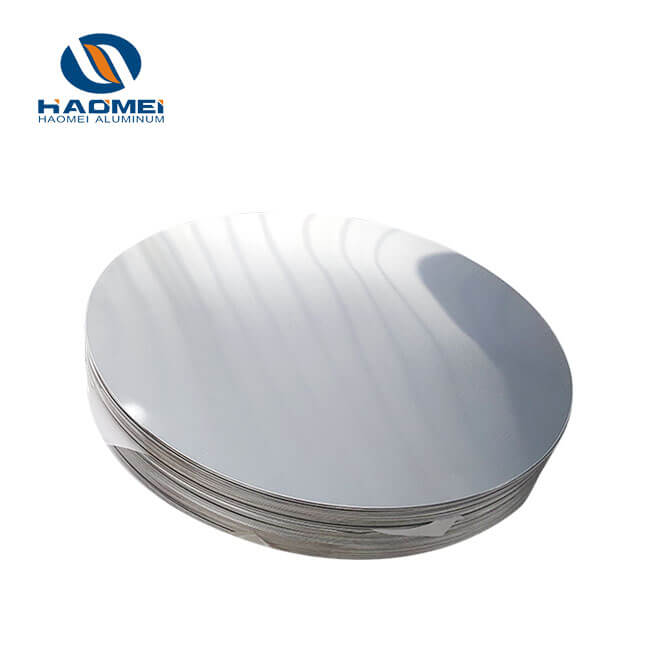

What Are Features of Aluminum Circle 5052

5052 aluminium circle has good corrosion resistance, welding performance, medium strength. Its comprehensive performance is better than 3xxx and 6xxx aluminum discs. Learn more.

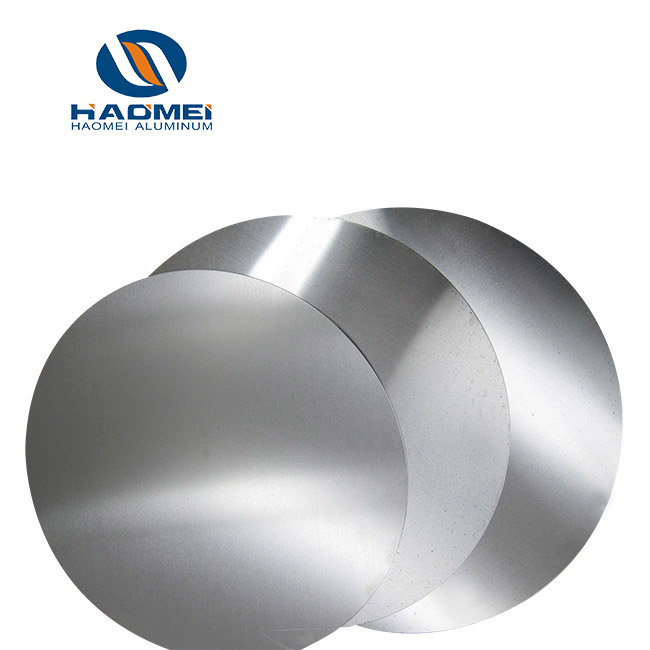

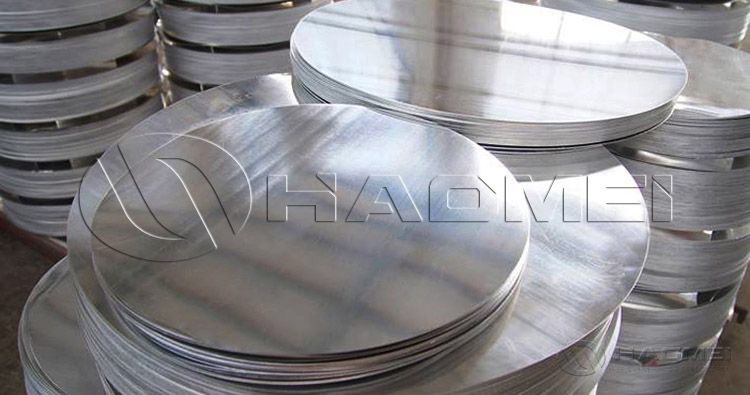

Aluminum circle 5052 belongs to Al-Mg alloys, in which the addition of magnesium and chromium greatly improves its corrosion resistance. In harsh environments such as the ocean and humidity, ordinary metals may corrode quickly, but 5052 aluminum discs can resist erosion and maintain the integrity of their own structures.

For many metal processing, welding performance is crucial. 5052 aluminum discs excel in this aspect. They can easily adapt to various welding processes. For example, common MIG welding can achieve single-sided welding and double-sided forming. The strength of the welded joint can reach 85% of the parent material, and the fatigue strength of the welded joint can reach 70% of the parent material.

5052 aluminum discs have medium strength, and the tensile strength of 5052-H32 state is 230MPa. At the same time, it has good cold processing performance, and can still maintain good plasticity during semi-cold hardening, which is easy to process into various complex shapes.

Its density is relatively low, which makes the products made of 5052 aluminum discs lighter, which has great advantages in today's pursuit of lightweight. And it also has good thermal conductivity, which can play an important role in some scenes that require heat dissipation.

1. Comparison with 3 series aluminum discs

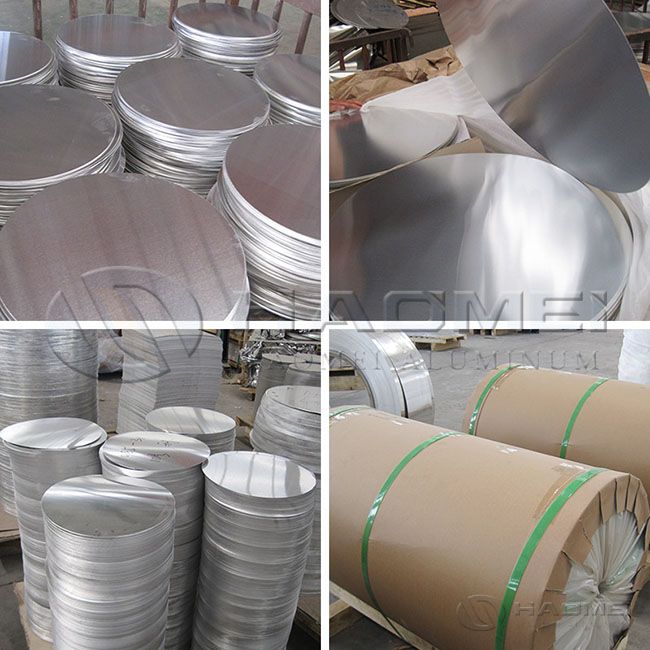

3 series aluminum discs (such as 3003) use manganese to enhance corrosion resistance, with an elongation of over 25% and low sensitivity to welding cracks. However, 5052 aluminum discs are superior in strength. The tensile strength of 5052-H32 state reaches 230MPa, which is higher than 145MPa of 3003.

In the application of structural parts with higher strength requirements, 5052 aluminum discs can better meet the needs. On some key structural parts of ships, 5052 aluminum discs can provide more reliable strength guarantee.

In terms of welded joint strength, the welded joint strength of 5052 aluminum discs can reach 85% of the parent material, far exceeding 3000 disc aluminium, and has obvious advantages in the manufacture of parts that need to be welded.

2. Comparison with 6-series aluminum discs

6-series aluminum discs (such as 6061) are heat-treatable strengthening alloys with high strength and good processing performance. However, 5052 aluminum discs perform better in corrosion resistance.

The corrosion resistance of 6061 aluminum discs circle in strong corrosion scenarios such as marine environments is not as good as that of 5052 aluminum discs. In marine engineering, if 6061 aluminum discs are used to make related parts, additional protective measures may be required to prevent corrosion, while 5052 aluminum discs can be directly used with their own good corrosion resistance, reducing costs and maintenance difficulties. The welding performance of 5052 aluminum discs is also relatively better, and it is more suitable for the production of some complex structural parts with high requirements for welding quality.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China