How to Judge the Quality of Aluminum Foil for Food

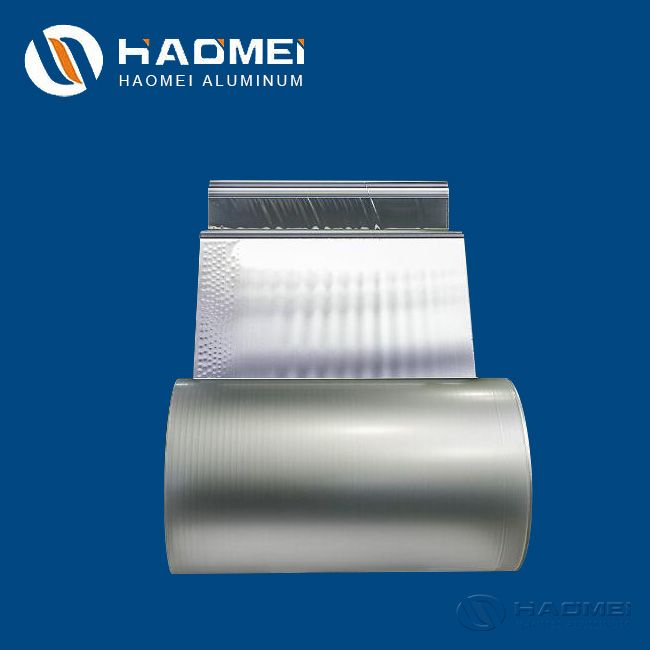

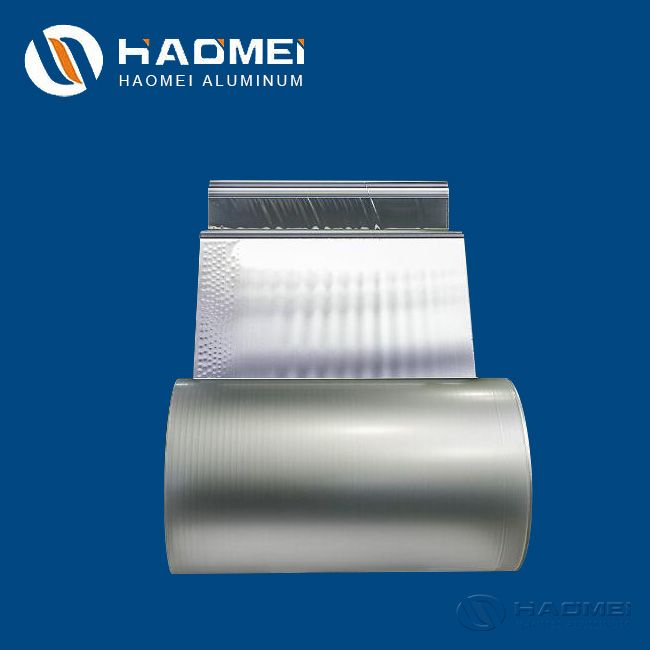

Whether the properties of aluminum foil for food reach the requirements influences its quality greatly. Here is a comprehensive introduction from Haomei, aluminium foil jumbo roll manufacturer.

Whether the properties of aluminum foil for food reach the needed standards has great effect on its quality. Its main properties include thickness, moisture permeability, number of pinholes, surface cleanliness and mechanical properties.

Thickness

Thickness

Thickness is one of the most basic and very important physical properties of aluminum foil. The thickness of the aluminum foil has a certain relationship with its barrier properties. As the thickness of the aluminum foil increases, its transmittance to oxygen, water vapor, light, etc. gradually decreases, and accordingly its barrier performance becomes higher.

In addition, it should also be pointed out that the thickness of the aluminum foil must be uniform. If the thickness of the aluminum foil is uneven, problems may easily occur in production.

Moisture permeability

Moisture permeability refers to the amount of water vapor transmission of aluminum foil under certain conditions. It reflects the moisture resistance of aluminum foil to a certain extent. The relationship between the thickness of aluminum foil and its moisture permeability can be seen in Table 1.

Aluminum foil thickness(㎛) | Moisture permeability(g/m2. 24h)

|

7-8 | ≤7 |

8-10 | ≤5 |

10-15 | ≤2.5 |

15-20 | ≤1.0 |

20-25 | 0 |

3. Number of pinholes

The presence of a large number of pinholes can easily penetrate oxygen, water vapor, and light, which will adversely affect the quality of the packaged food and even cause the food to spoil. Therefore, it is required that the number of pinholes of the aluminum foil should be as small as possible, and the hole diameter should also be as small as possible.

In general, the number of pinholes of 7μm thick aluminum foil should be less than 50 holes / m2, and the number of pinholes of 9μm thick aluminum foil should be less than 30 holes / m2.

4. Surface cleanliness

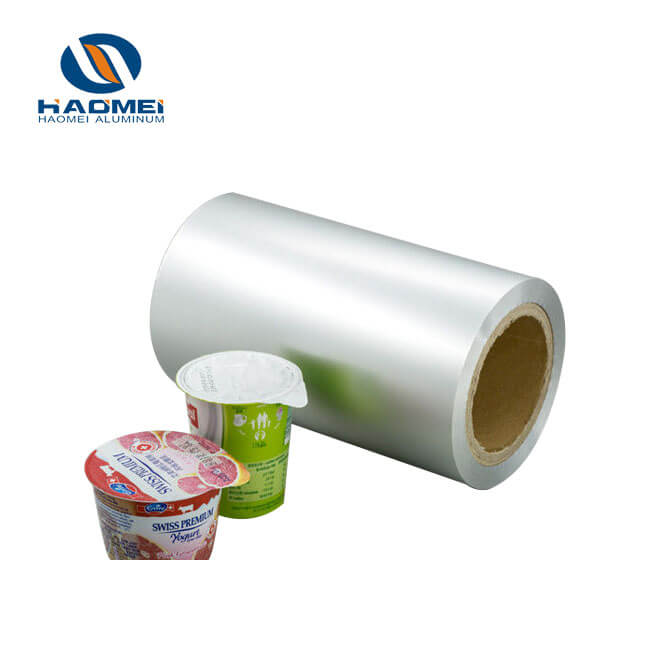

When aluminum foil is compounded with other substrates, its surface cleanliness has a decisive effect on the composite strength. If the surface cleanliness of the aluminum foil is poor and oil stains remain, the composite strength is relatively poor.

The residual amount of oil pollution determines the quality of the surface cleanliness. The surface cleanliness standards of aluminum foil are divided into five levels, A, B, C, D, and E. Among them, A level is the top grade. Haeomei aluminum foil for food packaging can reach Grade A, no oil stains.

5. Mechanical properties

The tensile strength, crack strength, elongation and other performance indicators of food grade aluminum foil have a certain impact on the quality of aluminum foil composite materials. Haomei Aluminum, a big aluminium foil jumbo roll manufacturer, has solid power to provide you quality aluminum foil.

Inquiry

TABLE OF Contents

Haomei Aluminum CO., LTD.

Tel/Whatsapp: +86-15978414719

Email: sale@alumhm.com

Website: https://www.alumhm.com

Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

Office Add: 1103, No.14 Waihuan Road, CBD, Zhengzhou, China